What are the differences between virgin, cold-pressed, pressed, and refined edible oil? How can refined oil be made delicious and healthy?

There are two methods for extracting vegetable oils: chemical extraction and physical pressing.

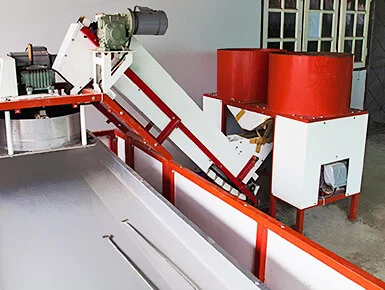

Physical pressing uses traditional techniques. Raw materials are carefully selected. After removing impurities and stones, the oil is crushed, steamed, and pressed to separate the oil from the raw material. This maximizes the integrity of the raw material and does not reduce the various natural nutrients in the edible oil. However, the residual oil content is high, resulting in higher costs.

Based on the pretreatment of the raw materials, the pressing method can be divided into cold pressing and hot pressing (cooked pressing).

The difference between cold pressing and hot pressing:

Cold pressing involves the complete physical and mechanical processing of unsteamed oil. Processing must be performed at temperatures below 60°C. The resulting cold-pressed oil does not require further refining like conventional oils; it can meet edible oil standards simply by filtering. This is a green and environmentally friendly production technology suitable for producing high-quality oils from high-oil-content oils. Cold-pressed oil is characterized by its complete preservation of nutrients and active ingredients, generally requiring no additives and allowing for long-term storage. However, its oil yield is low and its price is high. Cold-pressed oil is primarily used for high-end edible oils such as camellia oil and olive oil.

Hot-pressing involves cleaning and crushing the oil before subjecting it to high-temperature heating. This process causes a series of internal changes within the oil, such as destroying oil cells, denaturing proteins, and reducing oil viscosity, making it suitable for pressing and increasing oil yield. Traditional pressing methods employed in artisanal workshops are examples of

hot pressing. The oil produced by this method has a rich aroma, a darker color, and a higher yield than cold-pressed oil.

Virgin oil, as the name suggests, comes from the first extraction step, resulting in a high yield and purity. Virgin oil is produced from the oil using mechanical pressing or heat alone. The extraction process does not alter the oil's properties, and purification can be performed simply by washing, settling, filtration, and centrifugation. Virgin oil is suitable for consumption in its natural state, but not all virgin oils are edible, depending on the degree of purification. Taking extra virgin olive oil as an example, the International Olive Oil Council categorizes it primarily based on acidity: extra virgin (acidity ≤ 1.6), virgin (acidity ≤ 4.0), ordinary virgin (acidity ≤ 6.6), and lampante virgin (acidity > 6.6). The first three types of virgin oil can be consumed directly as long as other indicators meet relevant regulations. However, there is no specific acidity limit for the last type of virgin olive oil. Even if other indicators meet relevant regulations, it cannot be consumed directly and must be refined before consumption.

"Extra virgin"

Refined oil refers to crude oil that has been refined to remove impurities that are harmful to consumption and storage, resulting in a finished product that meets national quality standards. Most vegetable oils sold on the market have undergone a

refining process. This involves degumming, defatting, bleaching, deodorizing, dehydrating, removing impurities, and removing acidity from crude oil obtained through pressing or extraction processes under high temperature and pressure. While refined cooking oils may increase their smoke point and purify the oil, they also remove most of the beneficial ingredients in the oil, such as vitamins A, D, and E. For example, first-grade soybean or peanut cooking oils and margarine sold on the market are all refined vegetable oils.

Huatai Group is your partner in achieving superior quality and sustainable oil processing solutions.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ