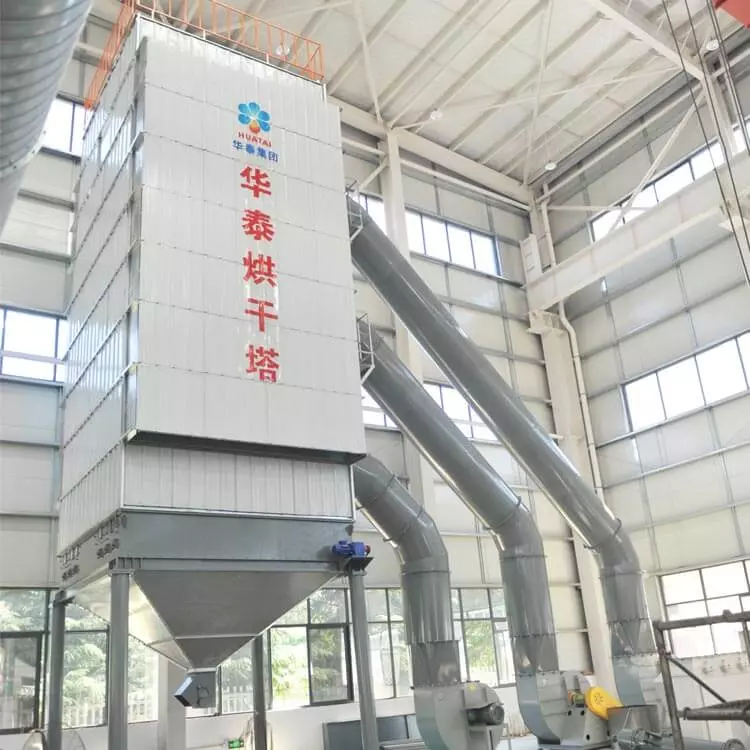

Huatai Intelligent Equipment Group grain drying tower is a commonly used grain drying equipment. It evaporates the moisture in the grain through the contact between hot air and grain, thereby achieving the drying effect. Its working principle mainly includes three parts: the generation, transmission, and drying process of hot air.

Huatai Group Grain Drying Tower Component

Hot air blower

As a heat source providing system, it generates high-temperature hot air

Hot air distribution system

Evenly distributes the hot air generated by the hot air blower into the drying tower to ensure that each grain can be fully dried.

Multi-layer drying tower

Composed of metal plates, the grain falls from top to bottom in the tower layer by layer and is fully in contact with the hot air.

Dehumidification system

Including dehumidification fans and dehumidification pipes, responsible for discharging the evaporated moisture and humid hot air from the grain out of the tower.

Cleaning and dust removal device

Prevent impurities from entering the system, while recovering dust in the hot air to keep the environment clean.

Automatic control system

Integrates the monitoring and adjustment of parameters such as temperature, humidity, and air volume to achieve intelligent management of the drying process.

![Huatai Intelligent Equipment Group grain drying tower Huatai Intelligent Equipment Group grain drying tower]()

Application of Huatai Group Grain Drying Tower

- Rapidly reduce the moisture content of the grain to the safe storage standard and reduce the risk of mildew.

- Improve the quality of grain and maintain the nutritional content and color of grain.

- Suitable for grain processing needs of different scales, from small farms to large grain processing companies.

Advantages of Huatai Group Grain Drying Tower

High efficiency and energy-saving

Using advanced heat recovery technology and optimized hot air circulation system to greatly reduce energy consumption and improve drying efficiency.

Uniform drying

The multi-layer tower design combined with the intelligent air volume distribution system ensures that each grain can be dried evenly to avoid local overheating or over-humidification.

Intelligent control

The integrated advanced automatic control system can monitor and adjust key parameters such as temperature, humidity, and air volume in real time to achieve precise control of the drying process.

Environmental protection and low noise

The use of low-noise fans and environmentally friendly fuels reduces noise pollution and harmful gas emissions and meets national environmental protection standards.

Strong adaptability

The drying process can be adjusted according to different grain types, moisture content, and climatic conditions to meet the personalized needs of different users.

Huatai Group Grain Drying Tower Cases

![Thailand 1000 TPD rice drying project Thailand 1000 TPD rice drying project]()

![300TPD rice and wheat drying project 300TPD rice and wheat drying project]()

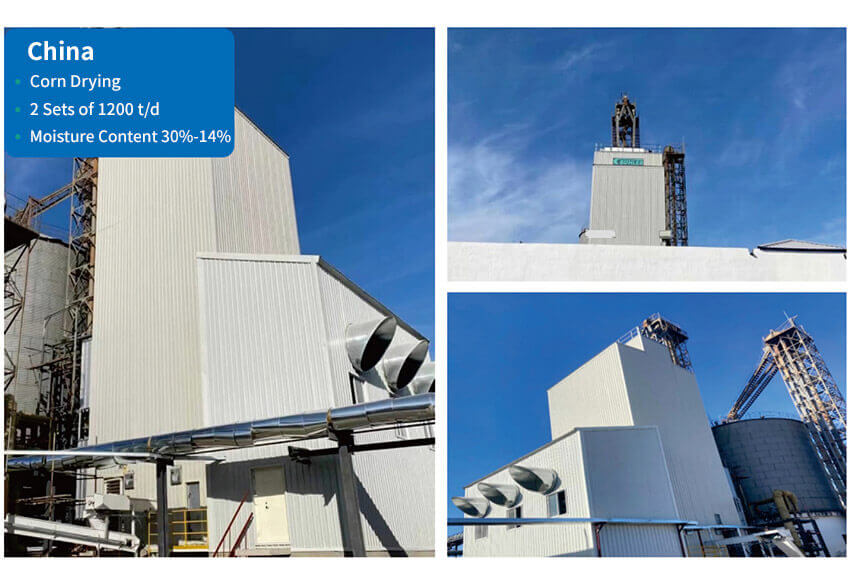

![China 1200TPD corn drying project China 1200TPD corn drying project]()

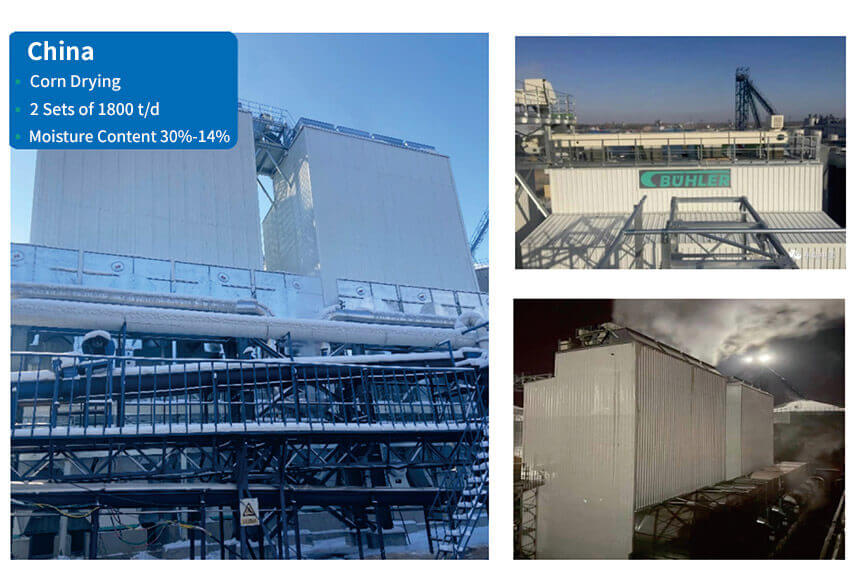

![China 1800TPD corn drying project China 1800TPD corn drying project]()

Huatai Group Grain Drying Tower Parameters

Equipment Type

Equipment Type

Application

Application