Huatai Group's steel silos, as modern storage equipment, are widely used in numerous industries including grain, cement, building materials, chemicals, and feed, due to their remarkable features such as sturdiness, durability, efficient storage, and flexible versatility.

Our silos incorporate advanced technology and premium materials, designed and manufactured in strict compliance with international standards to ensure exceptional quality and reliable performance in every unit.

Constructed from standardized prefabricated components, these silos are formed in the factory before being transported to the site for assembly. They offer convenient installation, short construction cycles, and the ability to be repeatedly dismantled and reassembled. This makes them suitable for various temporary or permanent storage needs, such as construction sites and grain transfer warehouses.

Huatai Group Steel Silo Advantages

Sturdy and Durable

Using high-strength, high-quality steel and advanced manufacturing processes, these steel silos offer excellent resistance to pressure, wind, and earthquakes. They can withstand harsh environments and the pressure of heavy material storage, ensuring a long service life and providing long-term protection for your investment.

Efficient Storage

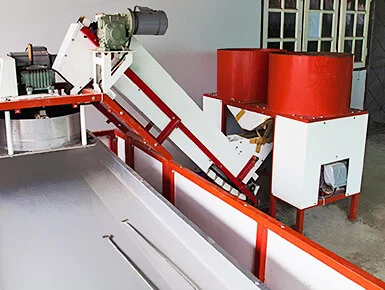

The scientific and rational structural design fully utilizes space and achieves large storage capacity. Furthermore, equipped with advanced loading and unloading systems, they enable fast and convenient material loading and unloading, significantly improving work efficiency and reducing operating costs.

Flexible and Diverse

With a comprehensive range of product specifications, we can tailor a customized steel silo solution to suit your site conditions, storage needs, and budget. Whether you need a small temporary storage silo or a large, professional storage facility, we can meet your needs.

Energy-Saving and Eco-Friendly

Excellent sealing effectively prevents material leakage and airborne contamination, minimizing environmental pollution. Furthermore, the steel silos' excellent thermal insulation properties effectively reduce energy consumption, contributing to energy conservation and environmental protection goals.

Easy Installation and Maintenance

The modular design allows for quick and easy installation, significantly shortening the construction period and minimizing the impact on production operations. Moreover, the maintenance cost of steel silos is low, and daily maintenance work is simple and easy, saving you time and energy.

![Huatai Group grain steel silo projects Huatai Group grain steel silo projects]()

Huatai Group Grain Steel Silo Parameters

Equipment Type

Equipment Type

Application

Application