Subcritical fluid extraction is performed under closed, oxygen-free conditions, making it simple, safe, and convenient to operate. The solvent used in subcritical extraction is a gas at room temperature and pressure, but becomes a liquid when pressurized. The basic principle of this process is to use a subcritical fluid countercurrent to extract oilseed germs or pellets (such as grape seeds, flax seeds, walnut kernels, wheat germ, peony seeds, pumpkin seeds, and evening primrose seeds) at room temperature and a certain pressure (0.3MPa-0.8MPa). The solvent in the mixed oil and meal is then decompressed and vaporized. The vaporized solvent gas is then compressed, condensed, and liquefied by a compressor for recycling. The heat required for solvent vaporization during the desolventizing process is partially absorbed by the system itself, while the remaining heat is supplied by the heating system. The process is as follows:

(1) Open the feed valve, load the pretreated raw materials into the extraction tank, close the feed valve, start the vacuum pump to exhaust the air in the extraction tank;

(2) Use the solvent pump to inject the subcritical fluid into the extraction tank to soak the raw materials, and start the stirring extraction;

(3) Use the solvent pump to extract the mixed oil from the extraction tank and pump it into the evaporation tank;

(4) Open the compressor outlet valve, start the compressor, connect the extraction tank and the compressor intake port, vaporize the residual solvent in the meal, and the solvent gas enters the compressor. After compression and condensation and liquefaction by the condenser, it flows back to the solvent turnover tank and is recycled. The meal is discharged from the extraction tank;

(5) Connect the evaporation tank and the compressor intake port, indirectly heat the evaporation tank, evaporate the solvent and separate it from the crude oil. The solvent vapor is compressed by the compressor, condensed and liquefied, and flows back to the solvent turnover tank and is recycled. The crude oil is discharged from the evaporation tank. Operating parameters: temperature 40°C, extraction pressure 0.4-0.7 MPa, extraction times 3-5 times (depending on the oil content of the raw materials); mixed oil concentration 10-40%, temperature 40-45°C, mixed oil evaporation temperature 45-60°C, mixed oil desolventizing vacuum -0.095 MPa; meal desolventizing temperature 45°C, residual solvent in crude oil <30 ppm, residual solvent in meal <500 ppm.

Subcritical fluid low-temperature extraction

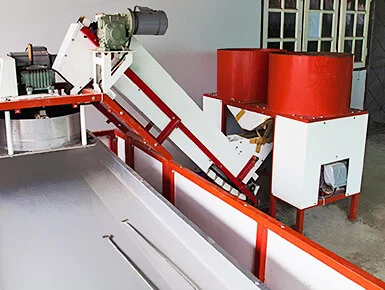

Subcritical fluid low-temperature extraction equipment is widely used in the extraction of small-variety edible oils and proteins, pigments, and plants.

We have successfully built numerous oil and protein production lines for grapeseed oil, wheat germ oil and protein, linseed oil and protein, pumpkin seed oil and protein, walnut oil and protein, almond oil, sea buckthorn seed oil, microbial oil, peony seed oil, coix seed oil, sugarcane wax, pyrethrum oil, mealworm oil and protein, and evening primrose seed oil.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

Subcritical fluid extraction is performed under closed, oxygen-free conditions, making it simple, safe, and convenient to operate. The solvent used in subcritical extraction is a gas at room temperature and pressure, but becomes a liquid when pressurized. The basic principle of this process is to use a subcritical fluid countercurrent to extract oilseed germs or pellets (such as grape seeds, flax seeds, walnut kernels, wheat germ, peony seeds, pumpkin seeds, and evening primrose seeds) at room temperature and a certain pressure (0.3MPa-0.8MPa). The solvent in the mixed oil and meal is then decompressed and vaporized. The vaporized solvent gas is then compressed, condensed, and liquefied by a compressor for recycling. The heat required for solvent vaporization during the desolventizing process is partially absorbed by the system itself, while the remaining heat is supplied by the heating system. The process is as follows:

Subcritical fluid extraction is performed under closed, oxygen-free conditions, making it simple, safe, and convenient to operate. The solvent used in subcritical extraction is a gas at room temperature and pressure, but becomes a liquid when pressurized. The basic principle of this process is to use a subcritical fluid countercurrent to extract oilseed germs or pellets (such as grape seeds, flax seeds, walnut kernels, wheat germ, peony seeds, pumpkin seeds, and evening primrose seeds) at room temperature and a certain pressure (0.3MPa-0.8MPa). The solvent in the mixed oil and meal is then decompressed and vaporized. The vaporized solvent gas is then compressed, condensed, and liquefied by a compressor for recycling. The heat required for solvent vaporization during the desolventizing process is partially absorbed by the system itself, while the remaining heat is supplied by the heating system. The process is as follows: