Walnut is known as one of the four major nuts and is rich in nutrients. The oil content of walnuts is as high as 65%~70%, which is the first of all oils. Walnut oil squeezed from walnut kernels also has rich nutrients. Walnut oil contains a variety of fatty acids needed by the human body. Walnut oil can effectively supplement the trace elements in the body.

There are many ways to eat walnut oil. It can be added to the baby’s complementary food to improve the baby’s brain development. Walnut oil can also be used to cook hot and cold dishes. It can also be used to make pastries.

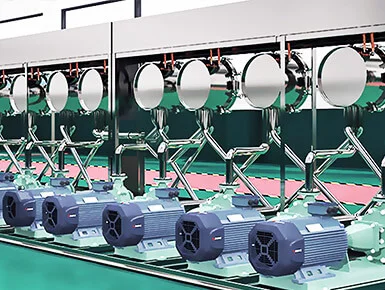

Complete equipment of walnut oil peeling and cold pressingPressing oil is the traditional processing method in China's vast walnut producing areas. Henan Huatai machinery developed walnut shelling and peeling cold pressing technology on the basis of traditional walnut pressing technology, which can obtain high-quality cold pressed walnut oil and high protein walnut powder from pressed cake. The process is as follows

Technological process: Walnut raw material → cleaning → shelling → peeling → drying → crushing → conditioning → cold pressing → first pressing walnut oil

Process Description: the walnut is first transported to the vibrating cleaning screen to remove impurities, and then the metal impurities and stones are removed by magnetic separator and specific gravity stone remover.

.jpg)

After cleaning, the walnut was shelled, and the walnut kernel and shell were separated.

The walnut kernel is peeled by water machine, then separated by separator, and finally dried by dryer.

The dried walnut kernel is crushed by crusher, and the crushed walnut kernel is transferred to the cold press for cold pressing after conditioning.

The process is cold pressing, the residual oil is 13-20%, and the conditioning temperature can be increased. For hot pressing, the residual oil rate can be reduced to 6%, and the unique aroma of walnut can be maintained.

Main equipment: vibrating cleaning screen, magnetic separator, specific gravity stone remover, sheller, peeling machine, crusher, dryer, tempering pot, etc.

Main features: cold pressing technology, conditioning and pressing temperature controlled at 60-80 ℃, can better maintain protein.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

Walnut is known as one of the four major nuts and is rich in nutrients. The oil content of walnuts is as high as 65%~70%, which is the first of all oils. Walnut oil squeezed from walnut kernels also has rich nutrients. Walnut oil contains a variety of fatty acids needed by the human body. Walnut oil can effectively supplement the trace elements in the body.

Walnut is known as one of the four major nuts and is rich in nutrients. The oil content of walnuts is as high as 65%~70%, which is the first of all oils. Walnut oil squeezed from walnut kernels also has rich nutrients. Walnut oil contains a variety of fatty acids needed by the human body. Walnut oil can effectively supplement the trace elements in the body..jpg)