Compared to the raw embryo extraction process, extrusion solvent extraction offers numerous advantages

Extrusion involves force-feeding the soybean flakes into the extruder and introducing high-temperature, high-pressure steam. Within the confined chamber of the extruder, the flakes undergo intense mixing, heating, extrusion, bonding, and gelatinization, resulting in structural changes. The bulk density of the extruded pellets increases, the cell structure of the embryo flakes is thoroughly disrupted, and the internal porosity and surface free oil increase. This increases the particle size and mechanical strength. During leaching, the solvent's penetration into the pellet layer is greatly improved, increasing the leaching rate and shortening the leaching time. This can increase the extractor's output by over 30%.

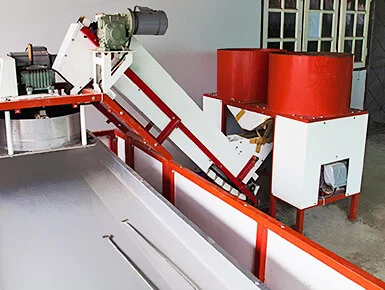

The extrusion discharge temperature is typically 110-120°C, and the moisture content after extrusion is 11-13%. The ideal inlet moisture content is approximately 8-10% and the temperature is 58-62°C. To ensure that the extruded pellets meet the leaching process's moisture requirements, drying and cooling are often required. Commonly used coolers include flat plate coolers and vertical coolers. Flat plate coolers dry and cool materials while they are being conveyed, while vertical coolers dry and cool materials in a countercurrent flow as they fall. Their compact structure and minimal footprint offer significant advantages. After cooling, the material has a moisture content of 8.5-10% and a discharge temperature of 58-62°C, making it ideal for oil extraction.

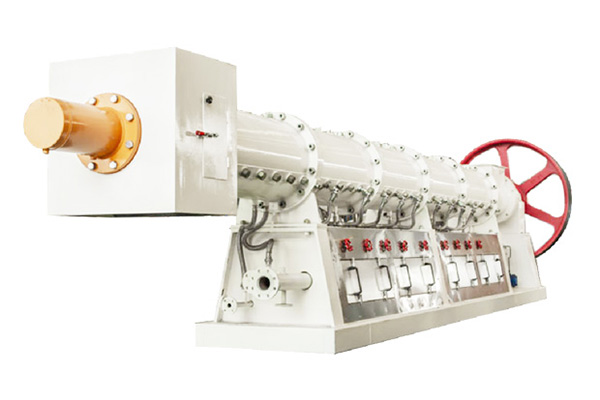

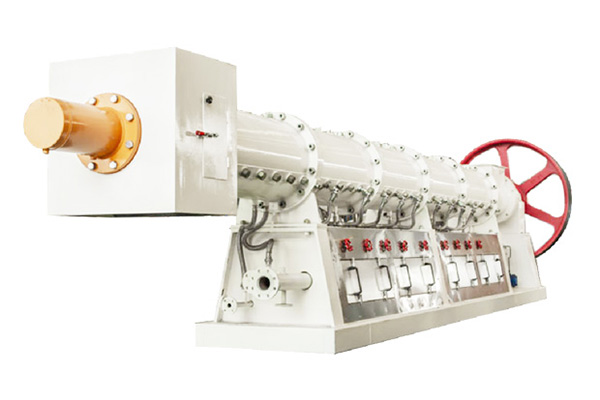

Inside the extruder chamber, a spiral shaft with intermittent screw blades is installed. Shear pins extend into the cylindrical wall, protruding into the spaces between the screw blades. When the machine operates, the rotating screw blades and shear pins mix and stir the materials thoroughly within the cylinder. The screw pitch gradually decreases from the feed inlet to the discharge outlet, causing the material volume to compress, ensuring better cohesion. Steam injection pipes on the cylinder wall spray 4-6 bar direct steam into the materials to increase moisture, elevate temperature, and soften the material.

Under the conditions of high-temperature cooking, mixing, extrusion, and pressure, proteins within the material soften and gelatinize, transforming into a cohesive gel-like substance. The elastic nature of gelatinized proteins enables the formation of porous extruded particles.Extrusion enhances soybean processing by compressing, heating, mixing, and steaming flakes to alter structure. It creates porous materials with improved properties, optimizing oil extraction efficiency and increasing yield.

Huatai Group provides best soybean oil mill plant, fast delivery, perfect after-sale services, and reasonable price, welcome to contact us!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ