To find a suitable palm oil machine, you can start from the following aspects

Clear production needs

Processing scale: Determined according to the output or expected output of palm fruit. For example, in a small plantation, the daily processing capacity may only be a few tons, and a single-screw palm oil press with a smaller production capacity can be selected, with a processing capacity of about 500kg/h. For large-scale palm oil processing plants, the daily processing capacity may reach dozens of tons or even hundreds of tons, so you need to choose a double-screw palm oil press, which has 1TPH, 5TPH, 10TPH, 15TPH, 50TPH, 100TPH, and other capacities to choose from.

Process requirements

If you just want to squeeze crude oil, a basic oil press is enough. If you want to produce high-quality refined palm oil, you need a complete production line, including sterilization tanks, fruit threshing machines, crushing tanks, oil presses, oil clarification equipment, oil drying equipment, and refining equipment, etc., to complete the refining processes such as degumming, deacidification, decolorization, and deodorization.

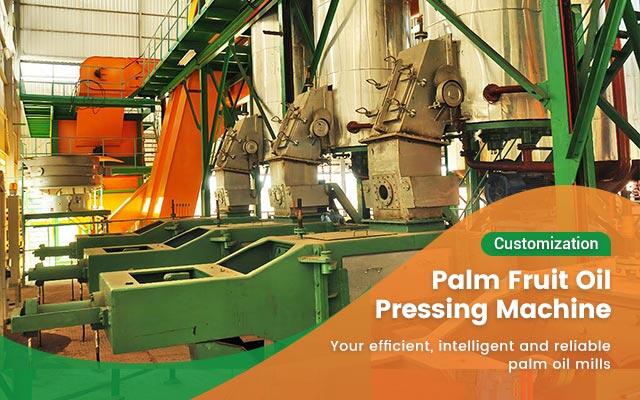

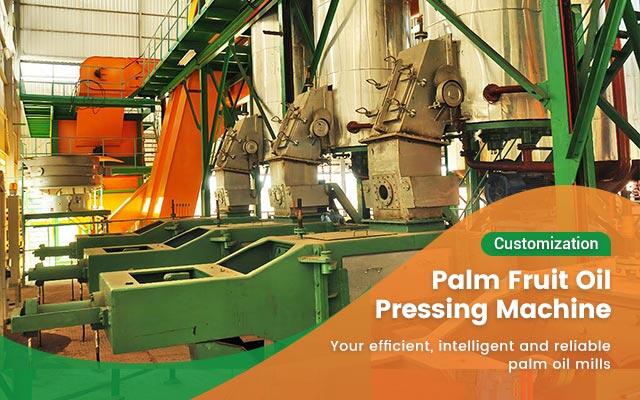

Understand the types and characteristics of equipment

Oil press: Single-screw palm oil press is suitable for small plantations; double-screw palm oil press is not easy to clog and has good oil output. It can be used alone or connected to a production line, which is suitable for situations with large processing capacity.

Refining equipment: Including intermittent refining equipment, semi-continuous refining equipment and fully continuous refining equipment. Intermittent refining equipment is suitable for small factories, with small investment and flexible operation; fully continuous refining equipment has high production efficiency and stable product quality, which is suitable for large factories; semi-continuous refining equipment is between the two.

Investigate brand and reputation

Industry reputation: Consult other

palm oil production companies to find out which brands of equipment have reliable quality, stable performance and good after-sales service. You can also ask in relevant industry forums and social media groups to obtain actual user experience and evaluation.

Brand awareness

Well-known brands usually have stricter standards and richer experience in R&D, production processes, quality control, etc. Some manufacturers specializing in the production of palm oil equipment, such as Henan Huatai Grain and Oil Equipment, have a high reputation and good reputation in the industry. Huatai Group has established many projects in Africa, such as Cameroon, Ethiopia, Nigeria, Democratic Republic of Congo, Congo-Brazzaville, Togo, Benin, Angola, Mozambique, Tanzania, Djibouti, Egypt, Kenya, Ghana, Cote d'Ivoire, Burkina Faso, etc., with rich and professional experience in palm oil equipment, tailor-made perfect solutions for customers, perfect after-sales service, and have won unanimous praise from customers. Enjoy a good reputation in Africa,

Consider price and budget

The prices of palm oil machines of different types, specifications and brands vary greatly. When choosing, you should consider it comprehensively according to your own investment budget. Generally speaking, the price of a small

palm oil press may range from several thousand yuan to tens of thousands of yuan, while the price of a complete large-scale palm oil refining production line may be as high as hundreds of thousands or even millions of yuan.

Focus on after-sales service

High-quality after-sales service is essential for the long-term and stable operation of equipment. Choose manufacturers with timely after-sales service response, high service quality, good service attitude, and comprehensive guarantees, including equipment installation and commissioning, operation training, maintenance, spare parts supply, etc.

Field inspection and trial machine: If conditions permit, it is best to conduct a field inspection at the equipment manufacturer to check the production process, material, manufacturing quality, etc. of the equipment. You can also ask the manufacturer to conduct a trial machine demonstration, visit the model room

palm oil project, observe the actual operation of the equipment, and understand its performance and oil yield and other indicators.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

To find a suitable palm oil machine, you can start from the following aspects

To find a suitable palm oil machine, you can start from the following aspects