Henan Huatai Cereals and Oils Machinery Co., Ltd. is at the forefront of innovation in the edible oil processing industry, offering advanced solutions for sunflower and cottonseed oil production. Our comprehensive pretreatment and pressing technology ensures high efficiency, quality, and sustainability, meeting global standards.

Advanced Pretreatment and Pressing Process

1. Low-Temperature Pressing Technology

Huatai's low-temperature pressing technology is designed to preserve the natural aroma and nutritional value of the oils. This process ensures high yield and quality while maintaining the integrity of the raw materials.

2. Pretreatment of Sunflower Seeds

Cleaning and Destoning: Sunflower seeds are first cleaned and destoned to remove impurities.

Peeling: The seeds are then fed into a peeling machine, which uses Huatai's patented centrifugal impact peeling technology. This ensures a high rate of intact kernels and a daily capacity of 150 to 200 tons.

Kernel Separation: After peeling, the sunflower kernels are separated from the shells.

3.Pretreatment of Cotton Seeds

Self-Cleaning Air Selection: Cotton seeds undergo self-cleaning air selection to remove impurities.

Magnetic Separation: The seeds are then subjected to magnetic separation to remove any metallic contaminants.

Crushing and Hulling: The seeds are fed into a cotton seed crusher, which breaks them down into smaller pieces.

4. Kernel Processing

Kernel Crushing: Both sunflower and cotton kernels are crushed into thin flakes to increase surface area and facilitate oil extraction.

Steam Conditioning: The crushed kernels are then conditioned with steam to prepare them for pressing.

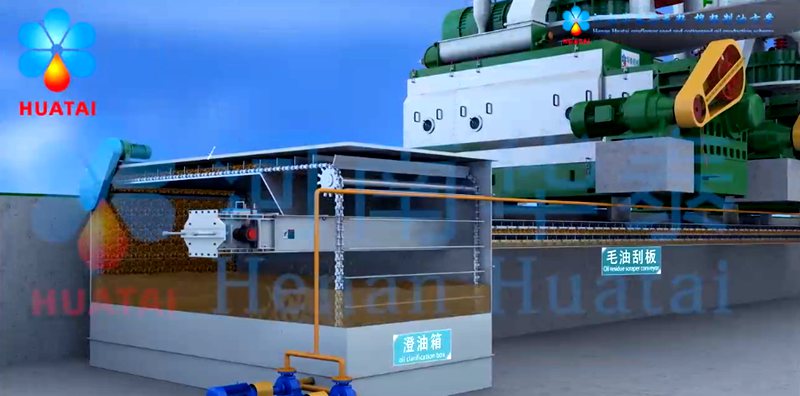

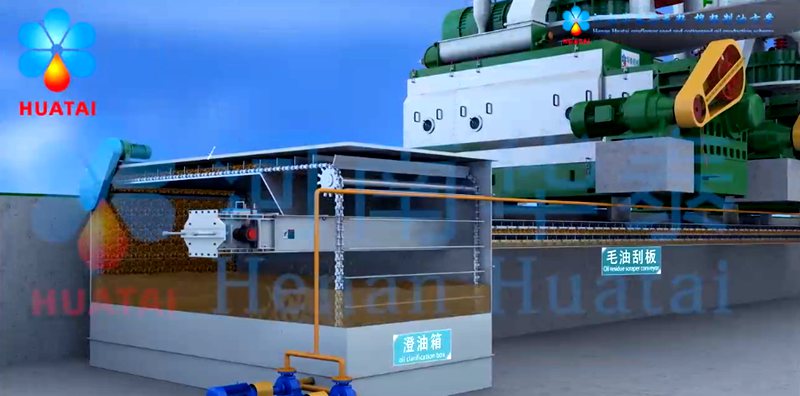

5. Pressing and Oil Extraction

Pressing: The conditioned kernels are fed into the pressing machine, where the oil is extracted.

Clarification and Filtration: The extracted oil is then clarified and filtered through a vibrating filter to remove any remaining impurities, resulting in crude edible oil.

Intelligent Control System

Huatai's proprietary intelligent control system is integrated throughout the entire production line. This system enables real-time monitoring of the production process, early warnings, and efficient energy management. The system is designed to be user-friendly and reliable, ensuring smooth operation and high-quality output.

Environmental Sustainability

Huatai is committed to sustainable practices. Our equipment is designed to minimize energy consumption and reduce waste. The entire production process is optimized for environmental friendliness, ensuring minimal impact on the environment.

Why Choose Huatai?

Innovation: Our patented technologies and advanced processes ensure high efficiency and quality.

Quality: High-performance machinery that guarantees superior oil quality.

Customized Solutions: Tailored to meet specific production needs, ensuring flexibility and scalability.

Support: Comprehensive after-sales support to ensure smooth operation and optimal performance.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ