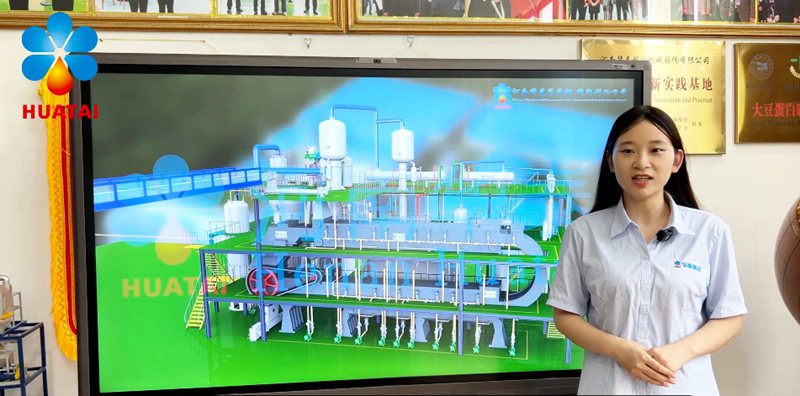

Henan Huatai Cereals and Oils Machinery Co., Ltd., a leading high-tech enterprise in the oil and grain machinery industry, is proud to introduce its fourth-generation sunflower and cottonseed oil extraction line. This advanced production line features state-of-the-art extraction technology, ensuring high efficiency, quality, and sustainability.

Advanced Extraction Process

1. Pre-treatment Workshop

The process begins in the pre-treatment workshop, where raw materials are fed into the extractor. The extractor is designed with adjustable material level heights and a non-permeable device to ensure efficient extraction. The raw materials circulate through the extractor, and the extracted material is discharged from the outlet.

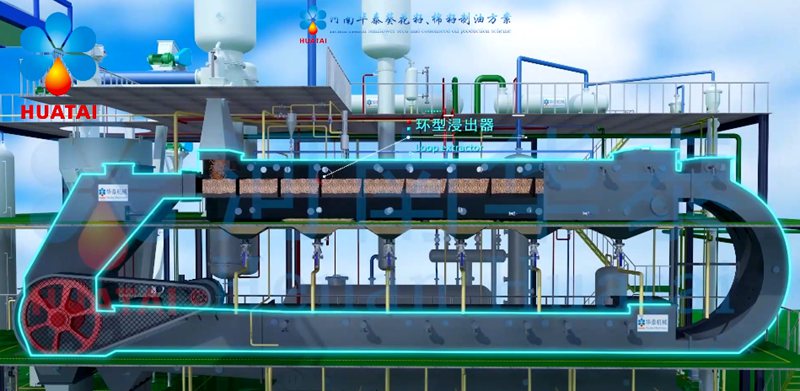

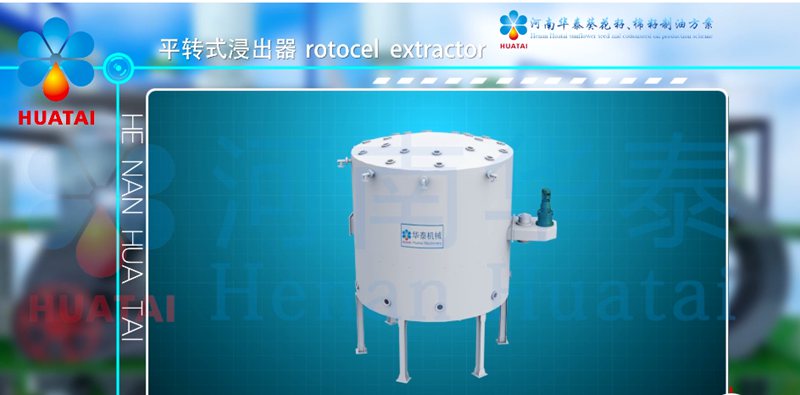

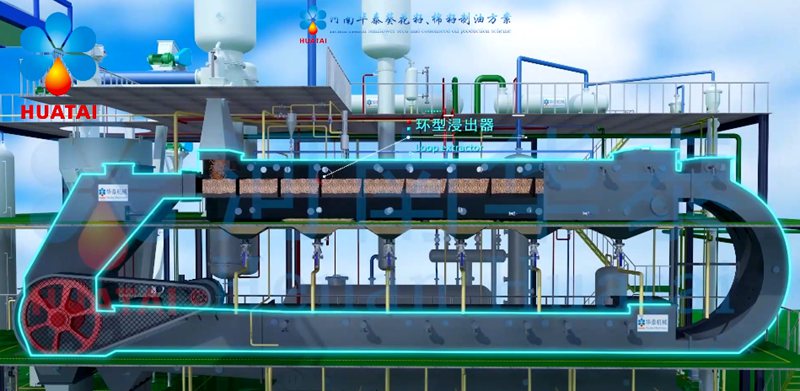

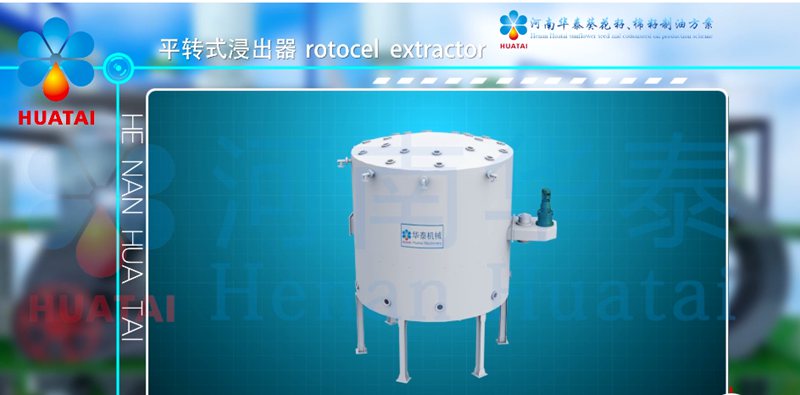

2.Extractor Design

Depending on the production capacity and raw material properties, the production line can be equipped with different types of extractors, such as drag chain extractors, flat rotary extractors, and ring-type extractors. These extractors are designed to optimize the extraction process and ensure high efficiency.

3. Wet Meal Handling

The wet meal is conveyed by a closed conveyor to the DTDC (Desolventizing, Toasting, Drying, and Cooling) machine. The DTDC machine consists of several layers: pre-desolventizing, desolventizing, drying, and cooling. Each layer features automatic material level control to ensure optimal processing conditions. The meal is then conveyed to the meal storage for weighing and packaging.

4.Mixed Oil Processing

The mixed oil from the extractor is separated from fine impurities using a centrifuge. The oil then undergoes a two-stage evaporation process, where the vapor and liquid are separated. The oil is then sent to the stripper tower, where it is further concentrated to meet national standards for crude oil through internal disc distribution.

5.Crude Oil Storage and Refining

After heat exchange, the crude oil is stored in a temporary storage tank, ready for the next stage of refining.

Why Choose Huatai?

Innovation: Our advanced extraction technology ensures high efficiency and quality.

Customized Solutions: Tailored to meet specific production needs, ensuring flexibility and scalability.

Quality Assurance: Our equipment is designed to meet international standards, ensuring pure and safe oil.

Environmental Sustainability: Our processes are designed to minimize environmental impact, promoting green manufacturing.

Contact Henan Huatai Cereals and Oils Machinery Co., Ltd. today to learn more about our advanced oil extraction solutions and how they can benefit your business.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ