Grain dryer

Grain dryer

Grain dryer is a mechanical equipment used to dry various types of grains. Since grain dryers are usually tower-type, they are also called grain drying towers. Grain dryers can be used to dry: corn, wheat, rice, soybeans, cereals and other grain crops.

Grain dryer is a kind of equipment that dries grains through high or low temperatures to achieve a safe storage target of less than 13% moisture content to prevent grain from mildewing during storage.

Downstream dryer

Grain and hot air move in the same direction, using a tower structure that combines a funnel-type air inlet and an angular box exhaust duct to increase the contact time between hot air and grain, thereby improving efficiency and reducing energy consumption. The wind temperature is between 150-250 degrees, and the single precipitation is 10-15%. It is the most efficient and has the largest precipitation range among all dryers. However, it is not suitable for crops with high heat sensitivity.

Mixed flow grain dryer: mostly in angular and parallel or staggered distribution on the drying tower body, which slows down the wind speed and grain flow speed, increases the contact area and time between grain and hot air, thereby reducing wind temperature and drying unevenness. It is suitable for crops planted in the south with low moisture but high heat sensitivity, such as rice, rapeseed, soybeans, etc.

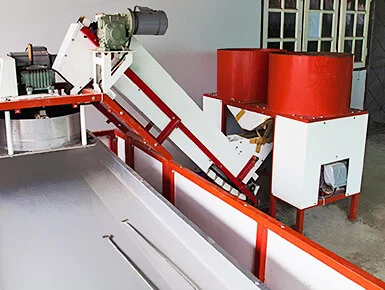

Henan Huatai grain dryer is suitable for drying corn, rice, wheat, soybeans, sorghum, millet, barley, oats, parboiled rice, and other grains, as well as oil crops such as rapeseed, sunflower seeds, soybeans, and cash crops such as coffee beans and chia seeds. It has extremely wide applicability. The hot air generated by the burning fuel in the hot air furnace is used as the drying medium. It mainly consists of a drying section, a slow cooling section, and a cooling section. The advanced process of multi-stage drying and slow cooling is adopted to ensure the quality of the grain after drying.

Grain dryers can be divided into corn, rice, wheat, rapeseed dryers, etc. according to the type of materials.

According to different working principles, it can be divided into: downstream dryer, mixed flow dryer, downstream mixed flow dryer, countercurrent dryer, downstream countercurrent dryer, mixed countercurrent dryer, cross-flow dryer and other models.

Performance characteristics

1. The equipment has a simple structure, small size, easy operation, no auxiliary equipment required, and is easy to transport and move.

2. The precipitation range is large, and the maximum precipitation range of a single machine can reach 25%.

3. It has strong adaptability and extremely wide applicability. It is suitable for drying high-moisture corn and rice in Northeast China.

4. The grain is dried thoroughly and evenly, the refrigeration is sufficient, and the cooling is thorough. After drying, the grain can be directly stored.

5. The equipment uses coal, rice husks or straw as fuel, which is converted into clean hot air after combustion and heat exchange. This is used as the drying medium. The circulating drying process is adopted. The dried grain is heated and precipitated evenly and fully without any pollution. The grain quality is good after drying.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

Grain dryer

Grain dryer