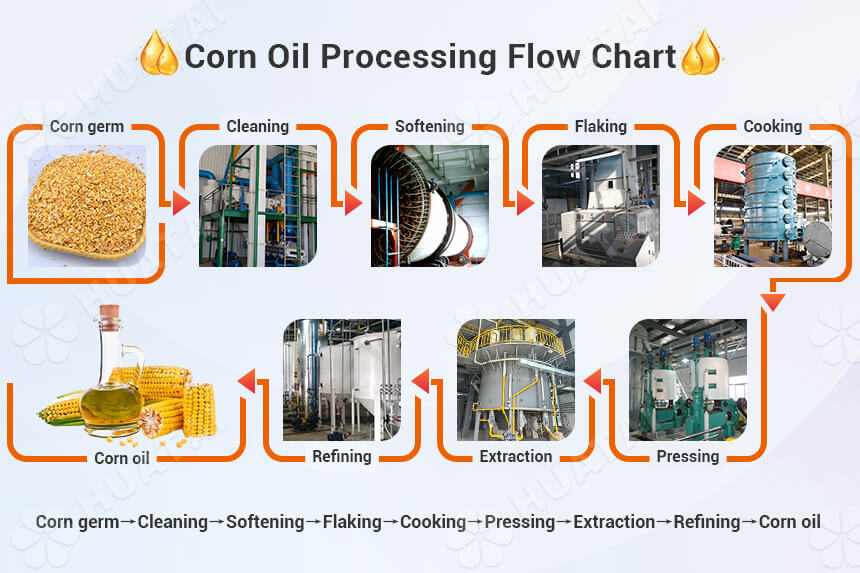

What Is a Corn Milling Line?

A

corn milling line is a complete set of equipment designed to clean, dehull, grind, and separate maize kernels into different end products such as:

Maize flour (for food industries, bakeries, and household use)

Corn grits (used in snacks, brewing, and cereals)

By-products like bran (often used for animal feed)

This production line integrates multiple machines, ensuring efficient processing and consistent product quality.

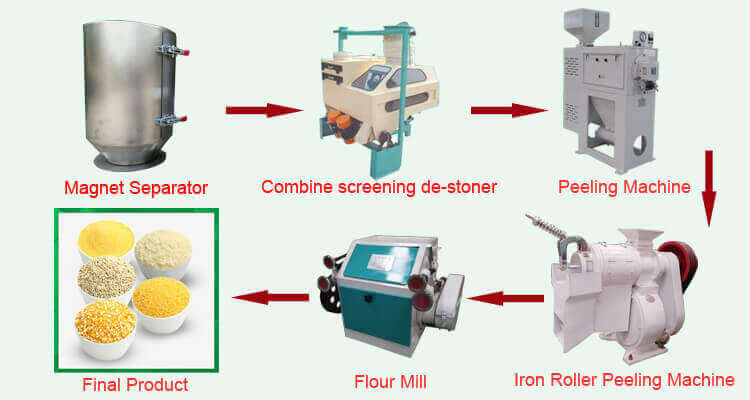

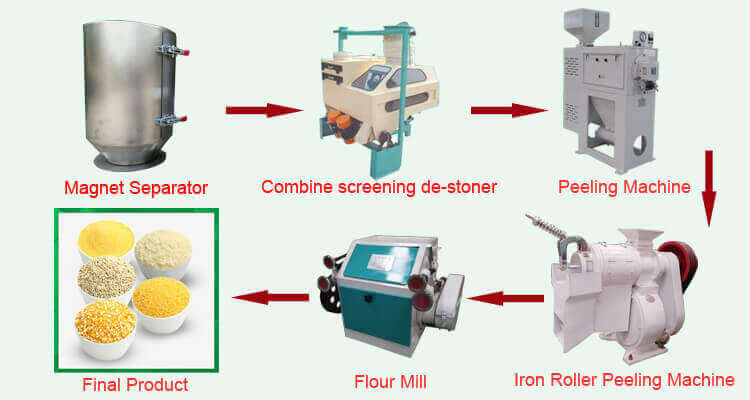

Key Components of a Maize Milling Line

Cleaning Section

Removes stones, dust, husks, and impurities to ensure food-grade processing.

Degermination & Dehulling Machine

Separates the maize germ and hull from the kernel, improving flour quality.

Milling Section

High-efficiency maize flour milling machines grind maize into fine flour or grits.

Grading & Sieving

Separates flour into different sizes based on customer requirements.

Packaging System

Automated packing machines ensure clean, accurate, and efficient bagging of the final product.

Advantages of a Modern Corn Milling Line

High Efficiency: Continuous operation with minimal manual labor.

Stable Quality: Advanced control systems ensure consistent flour fineness.

Versatility: Can produce maize flour, cornmeal, grits, and animal feed simultaneously.

Energy Saving: Optimized design reduces power consumption.

Scalable Production: Available in small, medium, and large capacities (from 20TPD to 1000TPD).

Applications of Maize Flour and Grits

Food industry: Bread, tortillas, biscuits, instant noodles, and snacks.

Brewing industry: Corn grits for beer and beverage production.

Animal feed: By-products such as bran and germ are valuable for livestock feed.

How to Choose the Right Corn Milling Line

When selecting a maize milling line, consider:

Production capacity (daily output in tons per day)

Final product requirements (flour fineness, grits size)

Automation level (manual, semi-automatic, or fully automated)

After-sales service and spare parts support

Energy efficiency and maintenance cost.

Huatai Group,a brand of 37 years one-stop supplier of grain milling,

grain processing Machine. Welcome your inquiry!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

(1)大豆竖版-封面.jpg)