Introduction

Corn oil, also known as maize oil or corn germ oil, comes from corn germ extraction. Corn germ contains 17% to 45% fat, accounting for over 80% of the total fat content in corn.

Research shows, corn oil contains 80%–85% unsaturated fatty acids, mainly oleic acid and linoleic acid. It is also rich in vitamin E and plantsterols, which offer antioxidant properties and help regulate blood lipids.

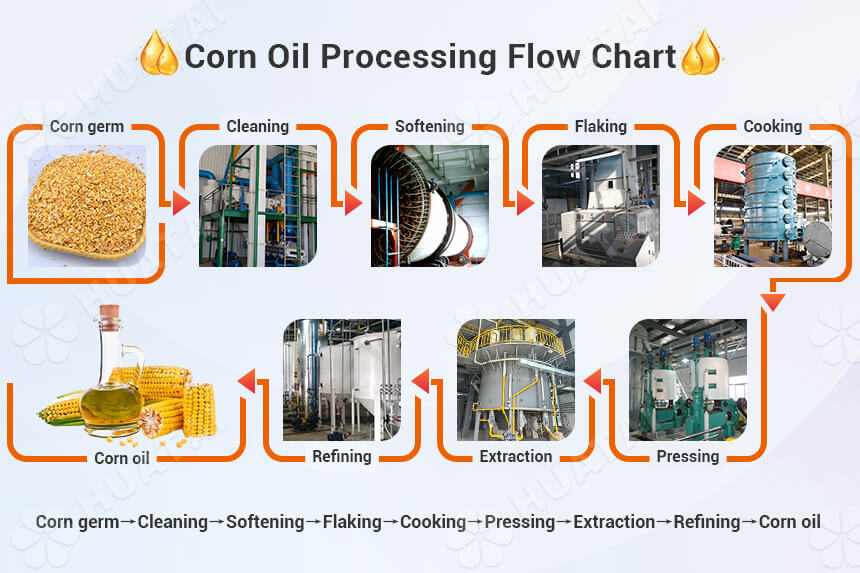

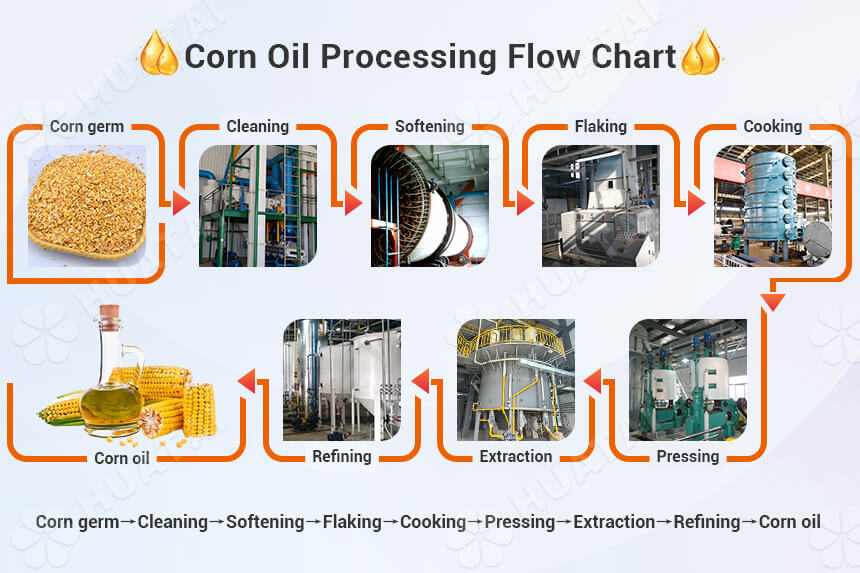

Below, I will introduce you to the complete process of extracting corn germ oil in a corn oil processing plant.

Step 1: Corn Germ Extraction (Three Methods)

Corn germ extraction is the first step in producing corn oil, directly determining the purity of the raw material, oil yield, and final oil quality. Based on raw material moisture content and processing methods, there are three different methods:

| Indicators |

Dry Method |

Wet Method |

Semi-Wet Method (Semi-Dry Method) |

| Process Principle |

Directly crush, dehull, and press corn embryos at safe moisture levels (≤15%). The method separates germs, endosperm, and hulls through air separation and screening, utilizing differences in specific gravity and suspension velocity. |

Soak corn in process water containing sulfurous acid for 48-72 hours. After softening, finely grind the corn, then use cyclone separators to separate germs. |

This method uses the differences in water absorption and elasticity between corn germ and endosperm. Moisten corn (adjusting moisture to 16-18%), allow brief conditioning, then dehull and break it. The process continues with embryo pressing and graded purification. |

| Germ Index Comparison |

Pure germ rate:60.29%-88.92% (starch factory materials); Crude fat content:High; Vitamin E content: High. |

Pure germ rate:84.11%-97.85%; Moisture content:3.51%-5.51%; Crude fat content:53.42%-54.77% (extremely high). |

Moisture content:9.09%-14.48%; Crude fat content:23.63%-26.94%; Volatile flavor:Fresh grassy sweet aroma. |

| Advantages |

Simple process, low investment, low energy consumption, no wastewater discharge. |

High germ purity and integrity, extremely high fat content, minimal protein denaturation, low risk of toxin contamination. |

Balances the benefits of dry and wet methods, achieves high germ yield and purity, consumes less energy than the wet method, preserves germ flavor compounds well. |

| Applications |

Comprehensive processing plants that mainly produce corn grits and corn flour. |

Corn starch processing plant. |

Plants developing edible corn germ products or focusing on high value-added by-products. |

Step 2: Corn Germ Pretreatment

Cleaning

This step removes corn flour, debris, husks, and magnetic metal impurities mixed with the germs. Plants typically combine double-layer vibrating screens with gravity destoners and magnetic separators to ensure raw material purity before pressing.

Softening

Adjusts the moisture content and temperature of the germ to enhance its plasticity. After softening moisture at 10%-12% to prevent the material from pulverizing when too dry or sticking to rollers when too wet during flaking.

Flaking

Roller mills press the softened germs into uniform flakes of 0.25-0.40 mm. This process destroys cell structures, increases surface area, and facilitates oil extraction and cooking.

Cooking

Cooking directly determines corn germ oil extraction efficiency and crude oil quality. By adjusting temperature, moisture, and time to denature and coagulate proteins, aggregate oils, and reduce viscosity.

Process parameters require adjustment based on germ flake purity. For example, at 70% purity, cooking temperature is 128-130°C, reduce moisture content to 1-2% before pressing.

![Automatic corn oil extraction machine for sale Automatic corn oil extraction machine for sale]()

Step 3: Corn Germ Oil Pre-pressing

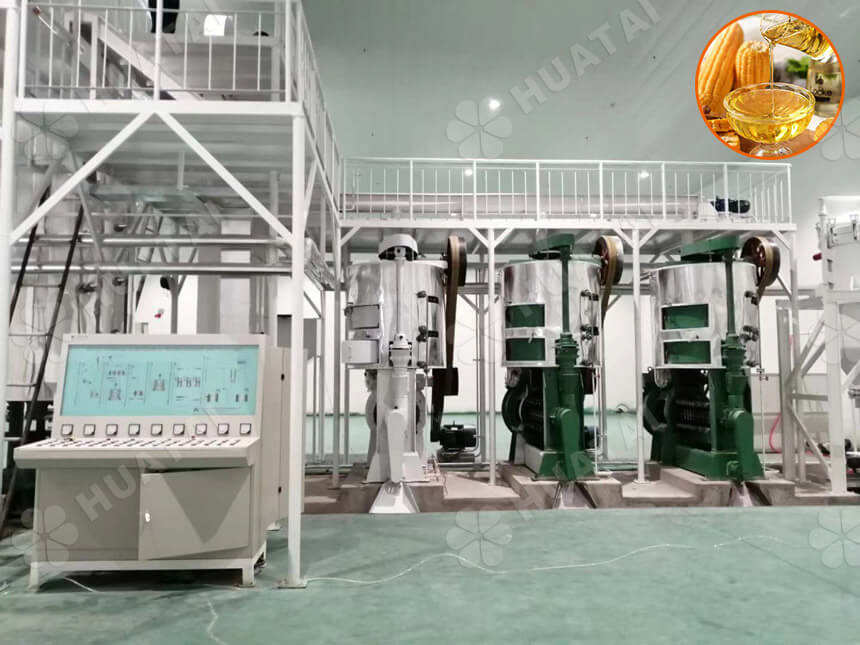

The corn germ oil pressing uses physical pressure to directly extract oil. It includes pre-pressing and single pressing, using screw oil press machine.

Pre-pressing requires pressure of at least 6.9MPa and controls residual oil in the cake at 6-7% to prepare for extraction. The physical structure (porosity) of the pre-pressed cake is critical to extraction efficiency.

Step 4: Corn Germ Cake Solvent Extraction

This process uses solvent extraction to further remove residual oil from corn germ pre-pressed cake, achieving a total oil yield exceeding 99%.

- Solvent soaking or spraying: The pre-pressed cake contacts the solvent (n-hexane) in countercurrent flow within the extractor. The oil dissolves and forms miscella (mixed oil).

- Wet cake desolventization: The solvent-laden wet cake requires desolventization and solvent recovery. Using the extractor and DTDC desolventizer, reduce residual solvent in the meal to below 650mg/kg under vacuum while lowering energy consumption.

- Mixed oil evaporation stripping: The mixed oil through multi-stage evaporation and negative pressure stripping to separates solvent, yielding crude oil.

- Solvent recovery: The system condenses solvent vapor generated throughout and recycles it after water separation, reducing solvent consumption.

![Crude corn oil refinery process flow chart Crude corn oil refinery process flow chart]()

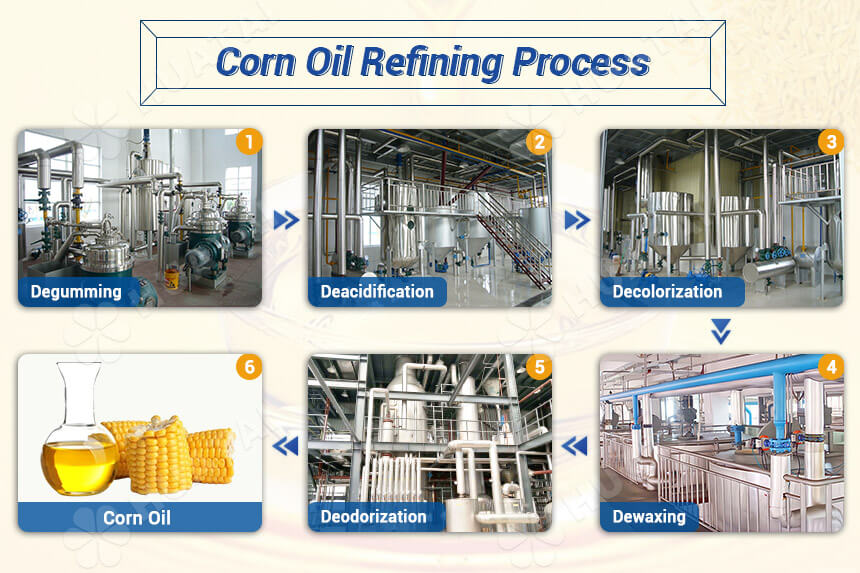

Step 5: Crude Corn Oil Refining

Crude corn oil must go through refinery to remove gums, free fatty acids, pigments, off-flavors, and waxes before people suitable for consumption.

Degumming

This process removes phospholipids. Henan Huatai Group's degumming process removes about 95% of phospholipids, reducing phosphorus content to below 18mg/kg without producing soapstock, thereby minimizing wastewater.

Deacidification/Neutralization

This step removes free fatty acids. For high-acid-value corn oil, physical deacidification is more efficient than alkali refining. It reduces free fatty acid content from 2.55% to 0.04%, minimizing neutral oil loss and trans fatty acid formation.

Decolorization

Adsorption removes pigments, trace metals, and residual soap particles. The two-stage process of clay pre-decoloration and re-decoloration reduces clay usage by 20%-50% compared to single-stage decoloration.

Dewaxing

Corn oil contains 0.01%-0.04% wax, affects low-temperature clarity. Using crystallization overflow tanks achieves automated continuous crystallization, crystal growth, and filtration. This process keeps the finished corn oil clear and transparent for over 30 hours at low temperatures.

Deodorization

Under high-temperature, high-vacuum conditions, deodorization removes off-flavors, free fatty acids, and peroxides. The optimized dual-tower deodorization process controls tocopherol (vitamin E) loss at around 19.9% while significantly reducing peroxide value.

![Ethiopian corn germ oil extraction plant project Ethiopian corn germ oil extraction plant project]()

Corn Germ Oil Extraction Project Introduction

Henan Huatai Intelligent Equipment Group customized a 15 ton per day corn germ oil production line and 3 ton per day corn oil refining line for an Ethiopian client, with shipment completed on July 16, 2024.

This project meets the Ethiopian people's growing demand for high-quality edible oil, promotes local agricultural processing industry development, improves agricultural product added value, and aligns with Ethiopia's national strategy to advance industrialization.

Since local clients lack professional technology and experience in oil processing, they need a reliable, worry-free, complete solution that ensures successful production startup. This involves not just equipment procurement, but the complex challenge of establishing an entire production system from scratch, including technical training and long-term support.

Therefore, Henan Huatai Group provided a complete corn oil production line and systematic engineering solution. It covers all stages from factory planning and design, equipment manufacturing, installation and commissioning, to producing qualified finished oil.

This project guarantees economic benefits while lowering the initial investment threshold and operational risks. The customized design ensures the production line matches local raw material characteristics, market capacity, and the client's investment budget.

Global Market Analysis of Corn Oil

| Country |

Annual Production (10,000 MT) |

Global Share |

Caption |

| America |

950 - 1,100 |

40% |

The world's largest corn producer, with advanced fuel ethanol and starch industries generating massive germ byproducts. |

| China |

650 - 750 |

25% |

The world's second-largest corn producer, supported by a vast starch and fermentation industrial system ensuring raw material supply, with a rapidly growing consumer market. |

| European Union |

250 - 300 |

10% |

Represented by France, Germany, and Italy, possessing mature starch and biofuel industries. |

| Brazil |

80 - 100 |

3.5% |

Corn production is growing rapidly, with feed and ethanol industries driving increased germ byproduct generation. |

| Mexico |

50 - 65 |

2.5% |

A major corn consumer, with stable germ feedstock generated by domestic food processing. |

| South Africa |

35 - 45 |

1.8% |

Africa's largest corn producer and deep-processing hub. |

| Canada |

30 - 40 |

1.5% |

Advanced agriculture and food processing sectors. |

| Argentina |

25 - 35 |

1.2% |

A major corn exporter, with ongoing development in domestic crushing and food processing. |

| India |

20 - 30 |

1.0% |

Significant corn production, but deep-processing industries remain developing with substantial potential. |

| Turkey |

15 - 25 |

0.8% |

Regional centers for starch and food processing. |

| Other countries |

200 |

8.7% |

\ |

| Total |

2,300 - 2,500 |

100% |

\ |

Tips: The global corn oil supply essentially is a by-product supply chain of corn deep processing (especially starch and ethanol production). Therefore, when you invest in a corn oil mill plant, you must closely monitor the layout and capacity changes in the corn deep processing industry.

Conclusion

Henan Huatai Intelligent Equipment Group not only supplies single machine but also undertakes turnkey corn oil processing plant projects. We integrate pretreatment, pressing/extraction, refining, and automated filling lines to ensure project delivery and efficient production startup. At the same time, it creates a safe, efficient, and profitable complete production system for clients.

With the goal of "Delivery Equals Production", Henan Huatai Group offers end-to-end services from factory planning and design, machinery manufacturing, installation and commissioning, to personnel training and production support. Feel free to contact us anytime to consult about corn oil extraction plant project solutions!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ