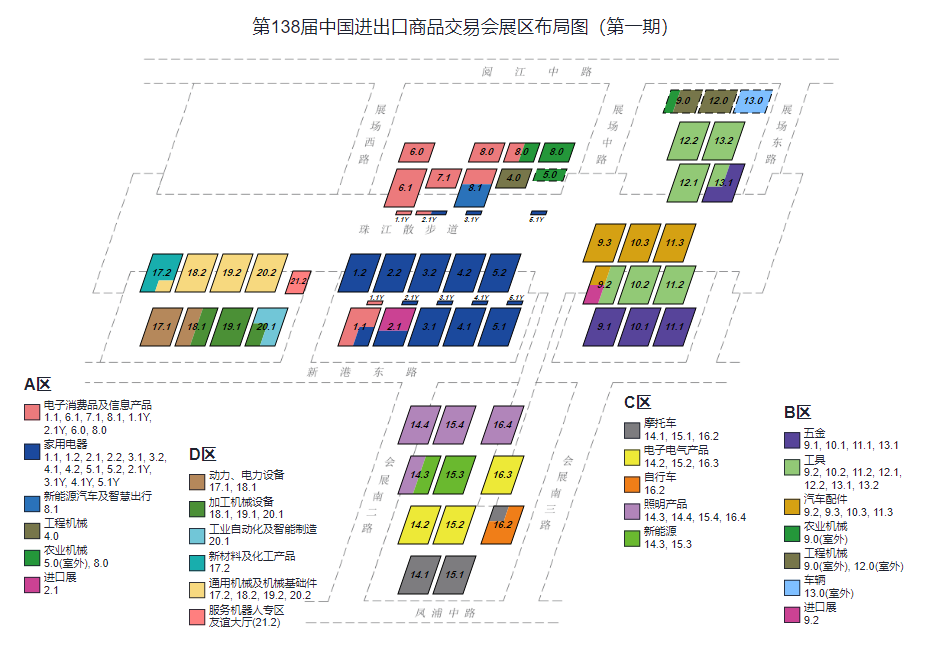

The core production process of corn oil is divided into pressing and

solvent extraction (the mainstream industrial methods). Both methods ultimately require refining to produce edible finished corn oil. The overall process follows a core flow: raw material pretreatment → oil extraction (pressing/solvent extraction) → crude oil refining → bottling and packaging. Corn oil uses corn germ as raw material (over 85% of corn oil is concentrated in the germ, with a germ oil content of 35%~45%). Throughout the production process, emphasis is placed on impurity removal, degumming, and deacidification to ensure the purity and edibility of the oil.

The following is a detailed process for large-scale industrial production, taking into account both pressing and solvent extraction methods, and also explaining the differences in simplified processes used in home/small workshops:

I. Extraction and Pretreatment of Corn Germ The raw material for corn oil is corn germ. The first step is to separate the germ from the corn, followed by pretreatment. This directly affects the oil yield and oil quality, and is the fundamental step in corn oil production.

Corn Germ Extraction

Industrially, this is achieved using a corn germ remover: After cleaning and removing impurities (sand, dust, and moldy particles), the corn is peeled, broken up, and graded to separate the germ from the endosperm and seed coat. The purity of the separated germ must be above 90%; low purity increases the difficulty of subsequent oil refining.

Supplement: Companies processing corn into starch and corn flour also extract the germ simultaneously, as this is the main raw material for corn oil, realizing the resource utilization of corn in deep processing.

Germ Pretreatment (Four Steps to Improve Oil Yield)

Drying: Fresh germ has a moisture content of approximately 15%~20%. It needs to be dried in a hot air dryer to a moisture content of 8%~10%. Too much moisture will lead to low oil yield and easy rancidity of crude oil; too little moisture will cause the germ to become brittle, resulting in excessive breakage and residue during pressing.

Screening and Impurity Removal: The germ is screened again to remove corn grits, sand, and metal impurities, preventing impurities from damaging equipment and contaminating the oil.

Softening: The dried corn germ is heated to 40-50℃ with steam or warm water to soften the cell walls, making it easier for oil to be extracted. This also helps maintain some elasticity in the germ, facilitating subsequent rolling.

Rolling: The germ is pressed into a thin, uniform cake (0.3-0.5mm thick) using a rolling mill. This breaks down the germ's cell structure, increasing the contact area between the oil and the pressing/leaching medium, significantly improving the oil yield (oil yield after rolling is more than 30% higher than direct oil extraction).

Pressing vs. Solvent Extract

Oil extraction is crucial for extracting oil from corn germ. Industrially, leaching is the dominant method (high oil yield, suitable for large-scale production; over 90% of corn oil in China uses this method). Pressing emphasizes "physical pressing, no chemical solvents" and is mostly used for high-end corn oil products. Both methods require further refining of the crude oil; the only difference lies in the oil extraction method and yield.

(I) Physical

Pressing Method (Cold Pressing + Hot Pressing, Hot Pressing is Commonly Used) This method extracts oil from corn germ cake using purely physical methods, without the use of chemical solvents. It meets consumer demand for "physically pressed oil," with an oil yield of approximately 30%~35%.

Hot Pressing (Mainstream): The corn germ cake is placed in a steaming and roasting pan at 120~140℃ for 15~20 minutes. This reduces the viscosity of the oil in the germ, further breaks down cells, and kills microorganisms, reducing rancidity. After steaming and roasting, the cake is fed into a screw press, where the oil is squeezed out of the germ cake by the screw shaft, yielding crude oil. The remaining residue is corn germ meal (which can be used as animal feed or for extracting protein powder).

Cold Pressing: The corn germ cake does not require steaming or roasting. It is directly pressed at room temperature using a low-temperature press, yielding an oil yield of approximately 25%~30%. However, cold-pressed crude oil has fewer impurities and retains more nutrients (such as vitamin E), and is often used for high-end cold-pressed corn oil, commanding a higher price.

Coarse Filtration: The pressed crude oil is initially filtered through a filter screen to remove germ residue and debris, yielding preliminary pressed crude oil.

Solvent Extract Method (Mainstream for Industrial-Scale Production)

Using food-grade n-hexane (non-toxic, volatile, and miscible with oils) as the extractant, the oil in the germ cake is fully dissolved. The solvent and oil are then separated by heating, achieving an oil yield of 40%–45%. This method boasts high raw material utilization, is suitable for large-scale production, and results in lower finished oil costs.

Leaching Extraction: The pretreated germ cake is placed in a rotary extractor, and food-grade n-hexane is added. The mixture is thoroughly mixed and extracted at 50–60°C for 30–40 minutes, allowing the n-hexane to completely dissolve the oil in the germ, yielding an oil-meal mixture.

Oil-Meal Separation: The mixture is separated through a screen and centrifuge, yielding an oil-soluble mixture (oil + n-hexane) and wet cake. The wet cake is desolventized and dried to become solvent-free corn germ cake (feed ingredient). Solvent Evaporation and Recovery: The oil-soluble mixture is fed into an evaporation tower and a stripping tower, heated at 80-100℃ to rapidly evaporate hexane, separating the crude extracted oil. The evaporated hexane is condensed and recovered, and can be recycled (industrial recovery rate exceeds 99%). The solvent residue in the finished crude oil is far below the national food safety standard (≤50mg/kg), posing no safety risks.

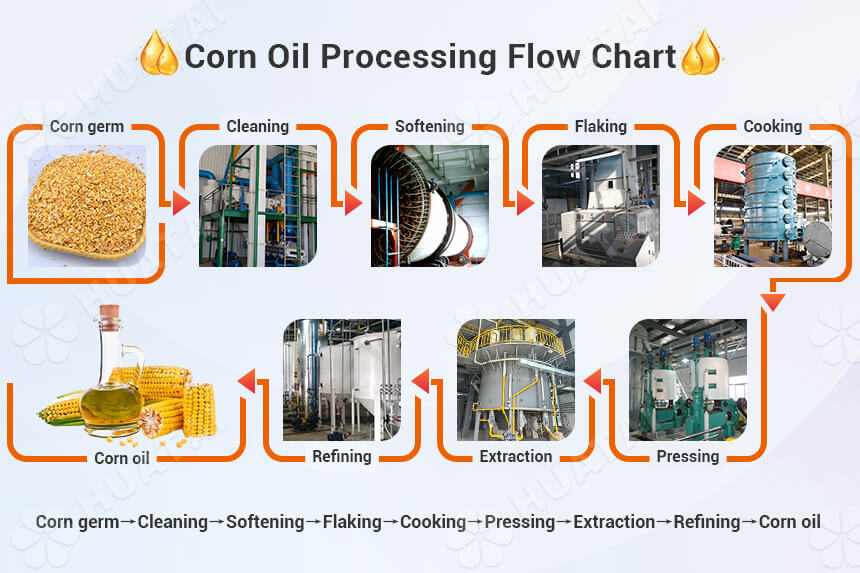

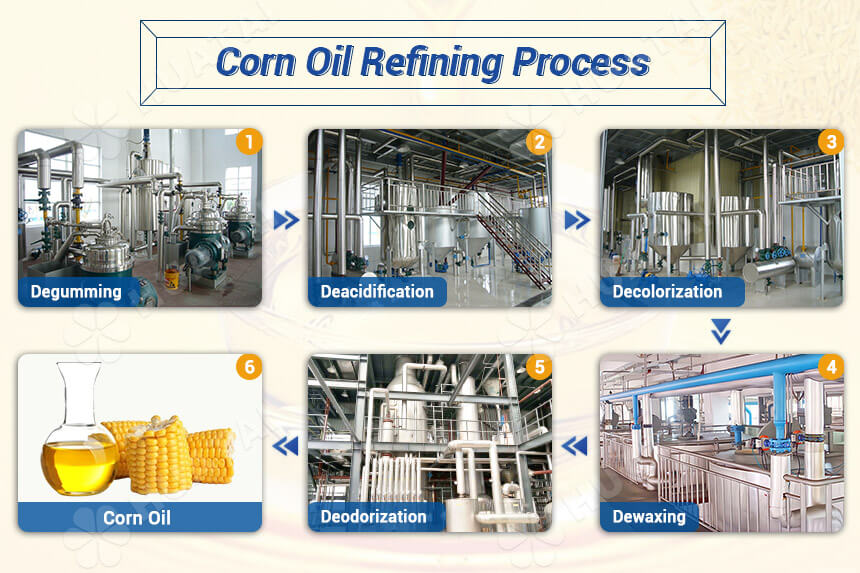

Crude Oil Refining

(A necessary step for all corn oil, determining the grade of the finished product) Crude oil obtained from pressing/extraction contains impurities (mechanical impurities, gums, free fatty acids, pigments, off-odors, etc.). Direct consumption will result in a bitter taste, easy rancidity, and will affect the taste and storage. Refining processes are necessary to remove impurities and produce refined corn oil. Based on the degree of refining, it can be divided into Grade 1, Grade 2, Grade 3, and Grade 4 (Grade 1 oil is the purest and suitable for frying and stir-frying; Grade 4 oil retains more nutrients and is suitable for cold dishes). Refining, industrially, is completed using continuous refining equipment, with a streamlined process:

Degumming: A suitable amount of warm water (80-90℃) is added to the crude oil. After stirring, the gums (phospholipids) in the oil absorb water and precipitate. These are then removed by centrifugation, preventing foaming and smoking during heating (phospholipids are the main cause of foaming).

Deacidification: Crude oil contains free fatty acids, which can cause a sour taste and high acid value. Food-grade sodium hydroxide solution is added to react with the free fatty acids in a saponification reaction, forming soap sludge precipitate. This precipitate is removed by centrifugation, reducing the oil's acid value and improving storage stability.

Decolorization: The degummed and deacidified oil is sent to a decolorization tower. Activated clay, activated carbon, and other decolorizing agents are added. The mixture is stirred and adsorbed under vacuum at 80-90℃ for 20-30 minutes to remove pigments such as carotenoids and chlorophyll, changing the corn oil from deep yellow to light yellow and clear. This process also adsorbs some odor-causing substances.

Deodorization: This is crucial for improving the taste of corn oil. The decolorized oil is sent to a vacuum deodorization tower, where high-temperature steam is introduced at 240-260℃ under high vacuum to strip away odor-causing substances such as aldehydes, ketones, and fatty acids, while preserving the natural aroma of corn oil. After deodorization, the oil has no bitter or off-flavors.

Dewaxing: Corn oil contains a small amount of wax, which crystallizes at low temperatures, causing the oil to become cloudy. The oil is cooled to 5-10℃ to allow the wax to crystallize, which is then removed by a filter press, ensuring the corn oil remains clear and transparent even at low temperatures (Grade 1 corn oil must be dewaxed).

Detoxification (Optional): This removes trace amounts of aflatoxin and other harmful substances from the oil through adsorption agents or ultraviolet sterilization, meeting national food safety standards.

After refining, refined corn oil is obtained. At this point, the corn oil meets edible standards and can be graded according to requirements (Grade 1 oil undergoes full-process refining, while Grade 4 oil only undergoes simple degumming and deacidification).

Post-Production Stages: Blending (Optional), Bottling and Packaging

Blending (Optional): Some corn oils will be blended according to requirements, such as with sunflower oil or peanut oil, to create blended oils; pure corn oil proceeds directly to the next step. Some high-end products will have fortified oils such as Vitamin E added at this stage.

Filtration and Inspection: The finished oil is filtered again through a precision filter to remove minute impurities, and then sent to a laboratory for physicochemical testing (acid value, peroxide value, solvent residue, color, etc.). Only after passing the tests can it be bottled.

Bottling and Packaging: The qualified corn oil is filled into glass bottles, plastic bottles, and oil drums using an automatic filling machine. It is packaged according to specifications: small bottles (500ml, 1L), family packs (5L), and commercial packs (20L). Then, it is labeled, capped, boxed, and finally stored in a warehouse (corn oil should be stored in a cool, dry place, avoiding direct sunlight; shelf life is approximately 18 months).

Core Standards and Characteristics of Corn Oil Production

National Standard Requirements: Edible corn oil must comply with GB 19111-2017 "Corn Oil," which sets strict limits on acid value, peroxide value, solvent residue, and aflatoxin. Grade 1 corn oil has an acid value ≤0.2mg/g and solvent residue ≤50mg/kg.

Product Characteristics: After refining, corn oil contains over 80% unsaturated fatty acids (linoleic acid accounts for 50%~60%), is rich in vitamin E and phytosterols, has a high smoke point (Grade 1 oil has a smoke point of approximately 230℃), and does not easily smoke or foam when heated, making it suitable for various cooking methods such as frying, stir-frying, braising, and deep-frying.

In summary, the core production process for industrial corn oil is: corn germ extraction → pretreatment → oil extraction (pressing/leaching) →

refining → bottling. Among these, leaching is the mainstream method for large-scale production, while the refining process determines the oil grade and quality. Physical pressing emphasizes "solvent-free" production and is mostly used in high-end products. The safety and quality of finished corn oil depend primarily on raw material selection, refining processes, and factory testing. Corn oil produced by reputable companies meets national food safety standards and is safe for consumption.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

The core production process of corn oil is divided into pressing and

The core production process of corn oil is divided into pressing and

(1)大豆竖版-封面.jpg)