Huatai Cereals and Oils Machinery Co., Ltd. (“Huatai”), a globally recognized leader in grain and oil engineering, has successfully delivered a fully integrated 20 m³/day wastewater treatment system along with a 10 m³/hour pure water preparation unit to a prominent edible oil producer in Tanzania. This export project demonstrates Huatai’s steadfast commitment to combining industrial productivity with ecological responsibility under the guiding philosophy of “Chinese Manufacturing, Green Sailing.”

The system is designed to operate synergistically with the client’s existing Huatai 50-ton/day sunflower seed oil processing line, forming a complete, environmentally sustainable production circuit. This comprehensive solution is tailored to meet the stringent environmental standards in Tanzania while enhancing the plant’s operational efficiency and long-term viability.

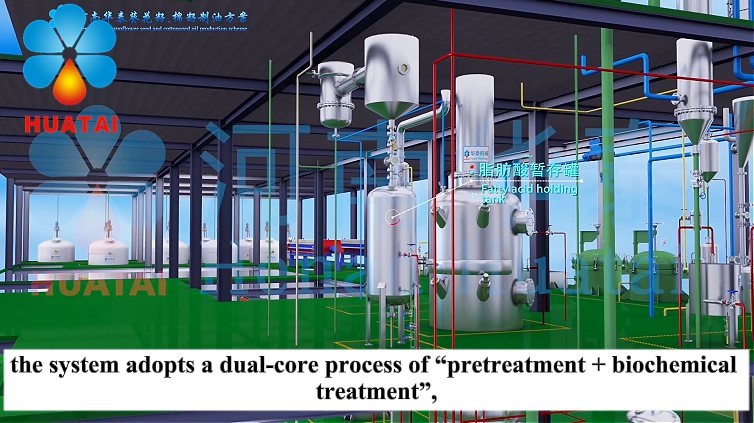

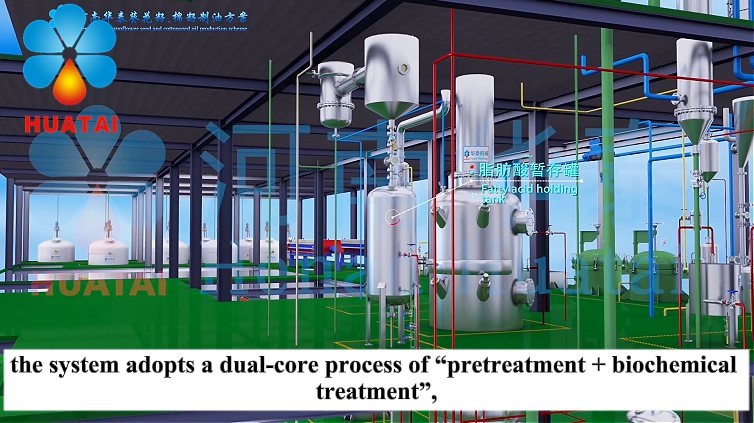

System Overview and Engineering Innovation

Grain and oil processing wastewater presents significant treatment challenges, characterized by high concentrations of fats, oils, grease (FOG), and complex organic compounds that contribute to elevated Chemical Oxygen Demand (COD). Huatai’s solution employs a robust dual-core “pretreatment + biochemical treatment” process engineered for high-efficiency purification and reliable, long-term compliance.

1. Advanced Pretreatment Stage: Two-Stage High-Efficiency Air Flotation

At the heart of the pretreatment phase is Huatai’s proprietary two-stage high-efficiency air flotation unit. This system integrates advanced demulsification and coagulation technologies, enabling the rapid and effective separation of free oils, greases, and suspended solids from the wastewater stream. This critical first step significantly reduces the pollutant load, protects downstream biological systems, and ensures stable influent conditions for optimal treatment performance.

2. Core Biochemical Treatment Stage: Intelligent Microbial Degradation

Following pretreatment, the wastewater enters the intelligent biochemical treatment section. Here, Huatai utilizes specially selected and acclimated microbial consortia within optimized reactor designs (such as sequencing batch reactors or membrane bioreactors) to thoroughly decompose dissolved organic pollutants. This biological stage is monitored and controlled via an automated system that adjusts aeration, nutrient dosing, and retention times in real-time, guaranteeing stable effluent quality that meets or exceeds local discharge limits.

3. Integrated Pure Water Preparation: Multi-Stage Purification Process

To support sustainable water usage within the production plant, Huatai’s 10 m³/hour pure water system employs a sophisticated “filtration–adsorption–membrane separation” process. This setup typically includes multi-media filtration, activated carbon adsorption, and reverse osmosis (RO) or ultrafiltration (UF) membrane technology, producing high-purity water suitable for boiler feed, equipment cleaning, or process reuse. This closed-loop approach minimizes freshwater consumption and reduces overall operational costs.

4. System-Wide Intelligence and Efficiency

The entire wastewater and water treatment plant is designed with smart automation at its core. A centralized PLC-based control system enables remote monitoring, automatic parameter adjustment, fault diagnosis, and data logging. The design emphasizes low energy consumption, minimal chemical usage, and strong adaptability to fluctuating wastewater characteristics, providing the client with a sustainable, low-operational-cost solution.

Huatai’s Integrated Approach: From Oil Seeds to Clean Water

This Tanzania project exemplifies Huatai’s unique capability as a single-source provider of integrated processing solutions. The seamless compatibility between the new wastewater treatment system and the existing sunflower oil line—both supplied by Huatai—eliminates interface risks, optimizes overall plant efficiency, and ensures unified technical support. It reflects Huatai’s holistic engineering philosophy: every production line should be efficient, profitable, and environmentally sound.

“The successful delivery of this system to Tanzania is a testament to our technical expertise and our commitment to global sustainable development,” stated a senior Huatai project engineer. “We are not just exporting machinery; we are exporting a vision of green industry, where economic growth and environmental stewardship go hand in hand. This project will help our Tanzanian partner enhance their production capacity while protecting local water resources.”

污水处理-封面_副本.jpg)

Huatai is a leading Chinese enterprise specializing in the research, development, manufacturing, and export of complete plants and machinery for cereals and oils processing. With over 38 years of experience, Huatai provides tailor-made turnkey projects, from single machines to fully automated production lines, serving a global clientele with a commitment to quality, innovation, and sustainable development.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

污水处理-封面_副本.jpg)