Core Components of a Rapeseed Oil Production Line

A complete rapeseed oil production line usually includes the following core equipment:

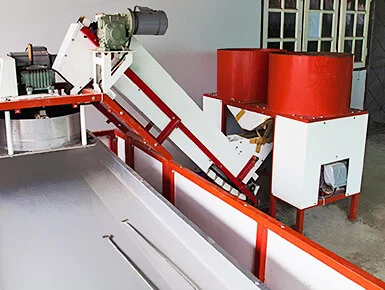

Pre-treatment equipment: cleaning machine, destoner, magnetic separator, dehulling machine, crusher, softening pot, flaking machine, etc.

Pressing equipment: cooking pot, oil press (screw oil press or hydraulic oil press)

Refining equipment: degumming, deacidification, decolorization, deodorization, dewaxing equipment, etc.

Auxiliary equipment: filter press, dryer, cooler, conveying equipment, electrical control system, etc.

Main Factors Affecting Rapeseed Oil Production Line Price

Production Scale

Production scale is the primary factor determining the price of a rapeseed oil production line. Based on different daily processing capacities, rapeseed oil production lines can be divided into

Small-scale rapeseed oil production line: 5-20 tons/day, suitable for individual businesses or small rapeseed oil processing plants

Medium-scale rapeseed oil production line: 20-100 tons/day, suitable for medium-sized rapeseed oil processing enterprises

Large-scale rapeseed oil production line: 100-1000 tons/day and above, suitable for large-scale rapeseed oil processing enterprises

Degree of Automation

The degree of automation directly affects equipment costs

Semi-automatic rapeseed oil production line: requires more manual operation, relatively lower investment

Fully automatic rapeseed oil production line: PLC control system, high degree of automation, low labor costs, but higher initial investment

Refining Grade

According to different finished oil quality standards, the rapeseed oil refining process can be divided into

Primary refining (degumming, deacidification, decolorization, deodorization)

Secondary refining (moderate refining, retaining more nutrients)

Solutions from Henan Huatai Cereals and Oils Machinery Co., Ltd.

As a national high-tech enterprise, Henan Huatai Cereals and Oils Machinery Co., Ltd. provides customized rapeseed oil production line solutions for its customers:

Technological Advantages

Possesses multiple national patented technologies, with mature and reliable processes

Adopts advanced low-temperature pressing and refining technology to maximize the retention of nutrients

Automated control system, easy to operate, saving labor costs

Energy-saving and environmentally friendly design, reducing energy consumption and meeting national environmental protection requirements

Price Range Reference

Based on Huatai Oil Machinery's project experience, the approximate investment range for a complete rapeseed oil production line is as follows:

Small-scale production line (5-20 tons/day)

Semi-automatic configuration: 300,000-800,000 RMB

Fully automatic configuration: 800,000-1,500,000 RMB

Medium-scale production line (20-100 tons/day)

How to Choose the Right Rapeseed Oil Production Line?

Define your needs: Determine the scale of the rapeseed oil production line based on your target market, budget, and business size.

On-site inspection: Visit Huatai Oil Machinery's production base and customer case sites.

Technical consultation: Communicate in detail with Huatai Oil Machinery's engineering team regarding process requirements.

Solution customization: Obtain a personalized rapeseed oil production line design plan and detailed quotation.

Comprehensive evaluation: Compare factors such as technical solutions, equipment quality, after-sales service, and price.

For the edible oil business, Huatai Machinery is a dependable supplier of top-notch engineering and construction services. Our goods include

oil press machines,

oil refinery plants, and packaging machinery, and we have years of experience developing, manufacturing, and installing machinery systems. In order to suit particular customer needs, we can provide bespoke solutions. Our team of professionals is committed to offering free consultation assistance and experienced direction to make sure your edible oil plant is a success. To find out more about our offerings and how we can support you in achieving your goals, get in touch with us right now.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

500tpd花生浸出生产线-封面_副本.jpg)

乌干达棕榈油精炼分提-封面.jpg)