Soy protein concentrate

Soy protein concentrate is produced from soybeans through a series of processes, including crushing, peeling, solvent extract, separation, washing, and drying. After removing oil, low-molecular-weight soluble non-protein components (primarily soluble sugars, ash, alcohol-soluble proteins, and various odorants), the resulting soy protein product contains at least 65% protein (N x 6.25) on a dry basis.

Soy Protein Concentrate (SPC) Production Line:

Raw Materials: Soybean Low-Temperature Soybean Meal (High-Temperature Soybean Meal)

Products: Food-Grade (or Feed-Grade) Soy Protein Concentrate

By-Product: Soy Syrup

Applications:

Applications:Food Grade: Food additive (protein content at least 70%).

Feed Grade: A feed additive particularly suitable for pigs, aquatic animals, calves, and pets.

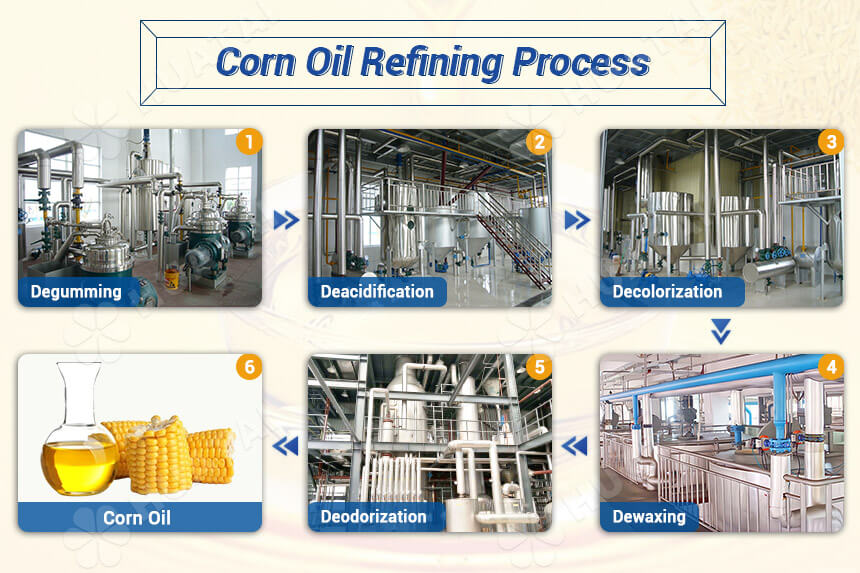

Process Features: Alcohol-based soy protein concentrate is extracted and separated from low-temperature soybean meal (high-temperature soybean meal) using edible ethanol. The product is then extruded, crushed, dried, and ultra-finely ground to produce alcohol-based soy protein concentrate. This product is water- and air-pollution-free, energy-efficient, and environmentally friendly, making it a leading future direction in soy protein production. Advantages of Soy Protein Engineering:

1. Utilizing low-temperature soybean meal secondary extraction ensures a product yield of 34-41% (2.7-3 tons of low-temperature soybean meal are required to extract 1 ton of protein powder).

2. Enzymatic hydrolysis and secondary granulation technologies rapidly gel the product, improving its solubility, dispersibility, and dusting properties, resulting in a high-quality product.

3. The production process is simple and easy to operate, ensuring stable product quality and easy for workers to master.

4. Optimized overall design and automated control of key production steps.

5. Continuous sterilization and deodorization minimize the beany odor of the product.

6. The entire production equipment meets food hygiene requirements, with all contact parts made of stainless steel.

7. Low equipment investment and low operating risk.

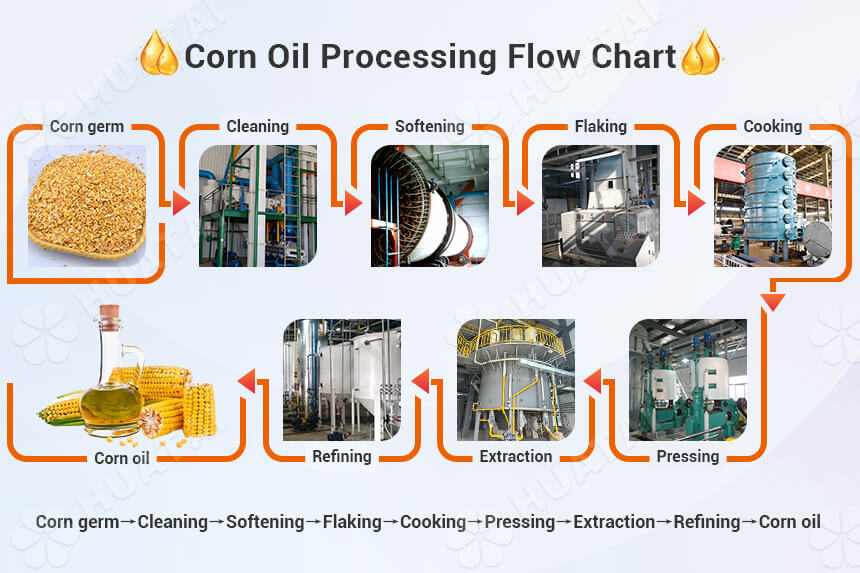

Henan Huatai Intelligent Equipment Co., Ltd., established in 1988, specializes in

oil pressing, extraction, refining, protein processing,

grain milling, starch processing, and environmental engineering. We provide clients with comprehensive solutions and turnkey projects for grain economic projects, including professional planning, design, R&D, equipment manufacturing, construction and installation, guidance and commissioning, and personnel training.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

Soy protein concentrate is produced from soybeans through a series of processes, including crushing, peeling, solvent extract, separation, washing, and drying. After removing oil, low-molecular-weight soluble non-protein components (primarily soluble sugars, ash, alcohol-soluble proteins, and various odorants), the resulting soy protein product contains at least 65% protein (N x 6.25) on a dry basis.

Soy protein concentrate is produced from soybeans through a series of processes, including crushing, peeling, solvent extract, separation, washing, and drying. After removing oil, low-molecular-weight soluble non-protein components (primarily soluble sugars, ash, alcohol-soluble proteins, and various odorants), the resulting soy protein product contains at least 65% protein (N x 6.25) on a dry basis.

(1)大豆竖版-封面.jpg)