Huatai Group specializes in developing complete soybean oil production lines, including shelling and conditioning stages. These lines integrate pretreatment, flaking and conditioning, solvent extraction, desolventizing, and refining. Manufactured from high-strength, corrosion-resistant materials and certified to ISO9001:2000, these lines meet the stringent requirements of global grain and oil processing plants for high yield, energy conservation, and environmental protection. These lines are widely used by medium and large oil and fat companies in Asia, Africa, and South America, supporting customized configurations to ensure increased production capacity and consistent quality. We offer a one-stop service from design to delivery, helping our clients achieve efficient and green production and seize opportunities in the international market.

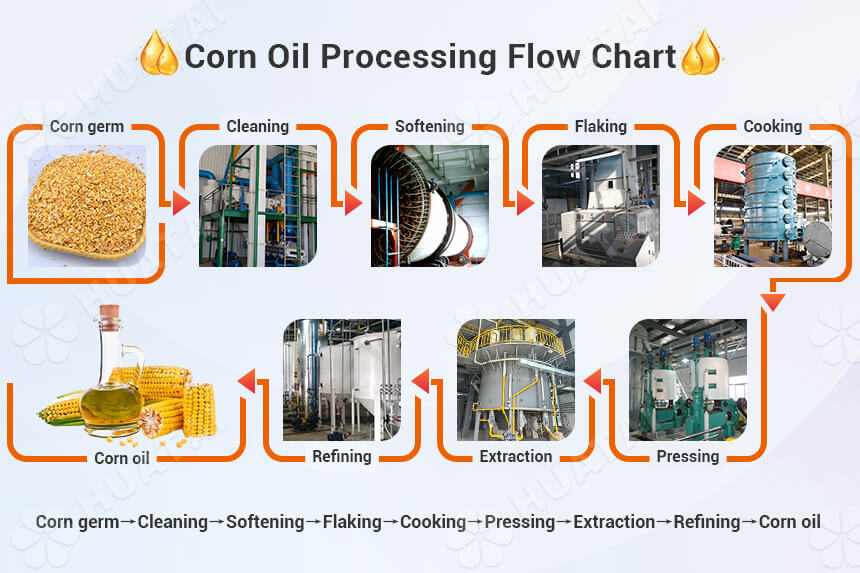

Solvent extraction is to use N-hexane to extract the oil from the processed oil seeds or cakes. The whole solvent extraction plant is anti-explosion considering of production safety. After solvent extraction, the oil residue is lower than 1%.

The solvent extractor first extract the crude soybean oil, then get two parts: miscella oil and the mixture of meal and solvents.

Through D.T.D.C system and miscella oil evaporation system, the solvent was separated from oil and meal. At last, condensate the gas state solvent into liquid state, and recover it for recycling use.

Since soybean oil that get from oil pressers is less, usually clients choose to add solvent extraction plant to get more soybean oil.

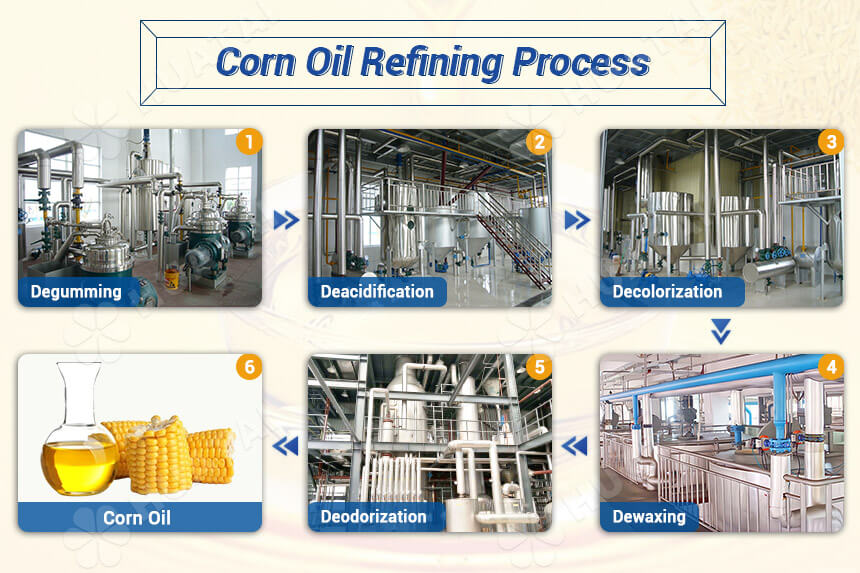

No matter after

pressing or solvent extraction, the soybean oil you get is crude soybean oil. Only after refining can it be edible oil. Henan Huatai Company's soybean oil refinery plant has three types according to different capacities and clients' requirements for final product oil.

Advantages and features

1. The entire production line covers six core steps: shelling, conditioning, pressing, extraction, desolventizing, and refining, achieving integrated operations from raw materials to finished products;

2. Use corrosion-resistant stainless steel materials to extend equipment life and reduce maintenance costs;

3. Support customized configuration to adapt to different scale and process requirements;

4. Comply with international standards (ISO certification), worry-free export;

5. Provide one-year warranty, remote technical guidance and on-site installation and commissioning services to ensure smooth production for customers.

Application Scenario

It is suitable for medium and large oil processing plants, especially for grain and oil companies in emerging market countries such as Asia, Africa and South America. It is used for large-scale production of high-quality soybean oil to meet the needs of domestic and foreign food processing and bioenergy industries.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

Huatai Group specializes in developing complete soybean oil production lines, including shelling and conditioning stages. These lines integrate pretreatment, flaking and conditioning, solvent extraction, desolventizing, and refining. Manufactured from high-strength, corrosion-resistant materials and certified to ISO9001:2000, these lines meet the stringent requirements of global grain and oil processing plants for high yield, energy conservation, and environmental protection. These lines are widely used by medium and large oil and fat companies in Asia, Africa, and South America, supporting customized configurations to ensure increased production capacity and consistent quality. We offer a one-stop service from design to delivery, helping our clients achieve efficient and green production and seize opportunities in the international market.

Huatai Group specializes in developing complete soybean oil production lines, including shelling and conditioning stages. These lines integrate pretreatment, flaking and conditioning, solvent extraction, desolventizing, and refining. Manufactured from high-strength, corrosion-resistant materials and certified to ISO9001:2000, these lines meet the stringent requirements of global grain and oil processing plants for high yield, energy conservation, and environmental protection. These lines are widely used by medium and large oil and fat companies in Asia, Africa, and South America, supporting customized configurations to ensure increased production capacity and consistent quality. We offer a one-stop service from design to delivery, helping our clients achieve efficient and green production and seize opportunities in the international market.

(1)大豆竖版-封面.jpg)