Starting an edible oil processing plant involves a critical decision: which processing method aligns with your production goals and market needs? At Huatai Cereals and Oils Machinery Co., Ltd., we leverage 30+ years of industry expertise to help clients navigate this choice. Below, we break down the three primary oil extraction methods—cold press, hot press, and solvent extraction—to guide your investment.

1. Cold Pressing: Preserving Natural Quality

Process: Hydraulic pressing at low temperatures.

Advantages:

- Retains natural flavors, colors, and nutrients (e.g., vitamins, antioxidants).

- Produces clear, aromatic oil ideal for premium segments.

- Best For: High-value oils like walnut oil, flaxseed oil, or specialty health-focused products.

2. Hot Pressing: Balancing Flavor and Yield

Process: Seeds are cleaned, crushed, roasted at high temperatures, and mechanically pressed.

Advantages:

- Enhances oil aroma and delivers a familiar, rich flavor.

- Higher oil yield compared to cold pressing.

- Best For: Traditional edible oils (e.g., peanut oil, sesame oil) where flavor and cost-efficiency matter.

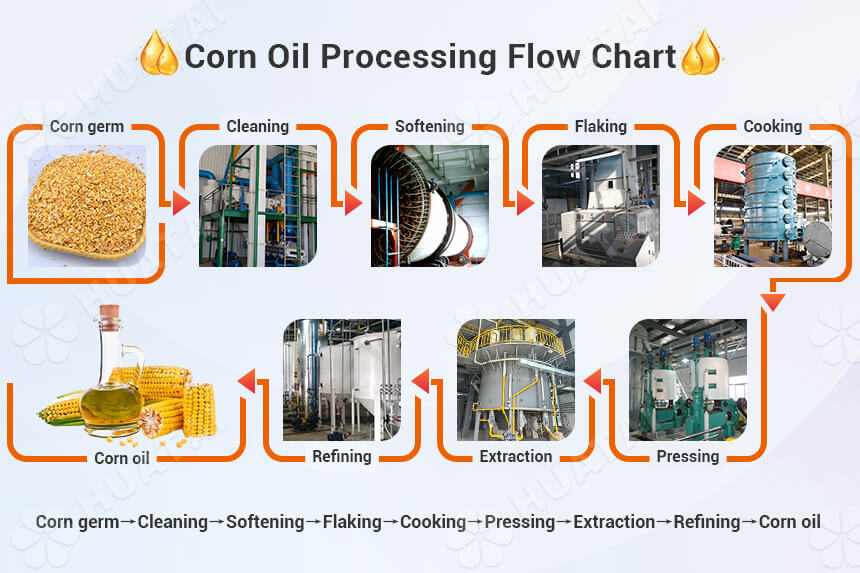

3. Solvent Extraction: Maximizing Efficiency

Process: Oil is extracted using food-grade solvents, followed by refining to remove residues.

Advantages:

- Highest oil recovery rate and lowest production cost.

- Produces pure, neutral-tasting oil suitable for large-scale markets.

- Best For: High-volume operations targeting mass-market consumers.

How to Decide? Key Considerations

- Target Market: Premium health markets favor cold pressing; mainstream consumers prefer hot-pressed or refined oils.

- Budget & Scale: Solvent extraction requires higher initial investment but offers the best long-term ROI for large plants.

- Product Diversity: Some factories combine methods (e.g., cold press for niche oils, solvent extraction for bulk).

Why Partner with Huatai?

As a globally trusted provider of oil processing solutions—serving 60+ countries—we offer:

-

Customized Machinery for all three methods.

-

End-to-End Support: From feasibility analysis to installation and training.

-

Proven Technology: Energy-efficient, automated systems tailored to your capacity.

Unsure which method fits your business? Our next article will dive deeper into selecting the ideal process based on raw materials, market demand, and financial goals.

Contact Huatai Today for a Professional Consultation!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

500tpd花生浸出生产线-封面_副本.jpg)