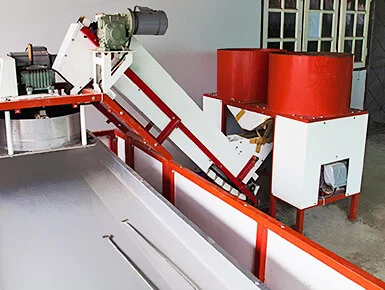

1. Drying and cleaning process

During the harvesting or drying process, rapeseed may be mixed with impurities such as sand, soil, and rapeseed stems and leaves. If these impurities are not effectively treated, they will not only cause poor quality of the cake, but also reduce the quality of the oil. In addition, if the oil contains sand, mechanical impurities, etc., it will also damage the oil pressing equipment. In order to ensure smooth production, impurities must be removed and cleaned before pressing.

(1)

Air separation Based on the difference in specific gravity and gas dynamic properties between oilseeds and impurities, wind power is used to separate impurities in oil. Air separation can be used to remove light impurities and dust in oil, and pressing can also be used to remove heavy impurities such as metals and stones. It can also be used to separate kernels and shells after shelling oil.

Features: Air separation can be achieved by adjusting the wind speed according to the physical properties of the oil. It can remove very light impurities such as dust. By adjusting the wind speed, a better separation effect can be achieved, and air separation has a role that cannot be replaced by other cleaning methods such as screening.

(2)

ScreeningScreening is a method of using magnets to remove metal impurities from oil. Although the content of metal impurities in oilseeds is not high, they are very harmful and can easily cause damage to equipment, especially some high-speed equipment, and may even lead to serious equipment accidents and safety accidents. They must be removed thoroughly.

(3)

Cleaning of side-by-side mud Side-by-side mud is mud that is similar in shape and size to or equal to oilseeds, and has a specific gravity that is not significantly different from that of oilseeds. Rapeseed, sunflower seeds, soybeans, and sesame contain a relatively high content of side-by-side mud. The cleaning of sludge utilizes the different mechanical properties of sludge and oilseeds. First, the oilseeds containing sludge are ground or pounded to pulverize the sludge, which is called sludge grinding. The dust is then removed by screening or air separation.

Features: It can remove difficult-to-remove impurities. After pounding and grinding, the sludge can be easily removed. A fan is used for dust removal, ensuring optimal equipment utilization.

2. Flour Rolling

Flour rolling aims to disrupt the cellular structure of the oilseed, increase its surface area, and shorten the oil's path for escape, facilitating oil extraction and improving steaming and frying.

Flour rolling utilizes mechanical forces to disrupt the oilseed's cellular structure and partially destroy its cell walls. Flour rolling transforms the oilseed from granules into flakes, reducing thickness and increasing surface area. This increases the surface area of contact between the sludge and the solvent during solvent extraction, shortening the oil's diffusion path and facilitating extraction speed and depth.

Features: The sludge is required to be thin and uniform, with minimal dusting and no oil leakage.

3. Steaming and frying

Steaming and stir-frying is an effective method for increasing rapeseed oil yield and a crucial step in oil production. Hot pressing involves heat-treating raw rapeseed before feeding it to an oil press, which can significantly increase oil yield. The quality of steaming and stir-frying can significantly impact the oil yield of rapeseed and other oilseeds.

4. Pressing

Due to the shape of rapeseed, which differs from other oilseeds, the requirements for the screw and press chamber during the pressing process differ. Production requires the screw to have a zigzag curve and conical surface to fully break down the rapeseed molecules and maximize oil yield.

Rapeseed Oil Refining Process

1.

Degumming and HydrationColloidal impurities in crude oil are primarily phosphorus. The presence of colloidal impurities such as phospholipids not only reduces oil quality but also promotes excessive emulsification between the oil and the alkali solution during alkali refining and deacidification, making separation of the soap nuts more difficult and increasing neutral oil loss. Therefore, they should be removed completely.

2. Deacidification and RefiningDeacidification of oils and fats primarily removes free fatty acids from crude oils, as well as small amounts of gums, pigments, and trace metals. Deacidification is a key factor directly affecting the oil refining yield and quality. The most widely used deacidification method in industrial production is alkali refining.

3. DecolorizationDecolorization is necessary to achieve the desired final product color and other impurities, while also providing favorable conditions for deodorization and refining. Decolorization is performed to achieve the desired final product color; remove relevant pigments and metals; further remove trace amounts of gums, such as soap beans and phospholipids, and certain odorous substances; remove polycyclic aromatic hydrocarbons and residual pesticides; and reduce the oil's peroxide value.

4. DeodorizationThe purpose of oil deodorization is to remove odor-causing substances and other volatile substances, improve the oil's odor and color, and enhance its stability. Deodorization can remove the characteristic odor of oils, odors produced during decolorization, and the odor of oil oxidation. During the deodorization stage, steam is directly injected into the distillation under vacuum and high temperature to remove it.

Huatai Oil Machinery provides best quality

canola oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ