Palm oil is one of the world's most widely produced and traded vegetable oils, essential for food, cosmetics, biofuels, and industrial applications. Huatai Grain and Oils Machinery Co., Ltd. specializes in designing, manufacturing, and installing complete palm oil processing plants, offering turnkey solutions that ensure high efficiency, superior oil quality, and sustainable operations. With over 38 years of experience and a presence in more than 60 countries, we are a trusted global partner in palm oil production.

Complete Palm Oil Processing Workflow

Huatai’s palm oil processing lines cover every stage from fresh fruit bunches (FFB) to refined, bleached, and deodorized (RBD) palm oil and palm kernel oil (PKO).

1. Sterilization

- Purpose: Halts enzymatic activity, loosens fruits from bunches, and prepares for threshing.

- Equipment: Horizontal or vertical sterilizers with steam injection systems.

- Capacity: 1–120 tons per hour (TPH) configurations.

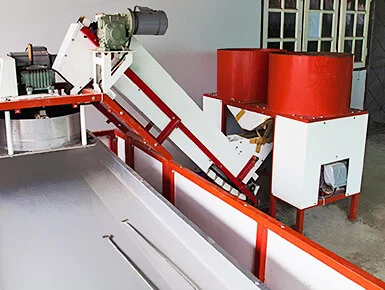

2. Threshing & Stripping

- Rotary drum threshers efficiently separate sterilized palm fruits from empty bunches.

- High recovery rate with minimal fruit damage.

3. Digestion & Pressing

- Digesters: Heat and stir fruits to break oil-bearing cells.

- Pressing: Huatai’s double-screw presses offer:

- Hydraulic bolt screw design for enhanced compression

- Opposite-rotation screws for maximum oil yield

- Energy-efficient operation with precise control

4. Clarification & Purification

- Crude Oil Clarification: Removes water and solids.

- Palm Kernel Recovery: Separates kernels from pressed fiber for PKO extraction.

5. Palm Oil Refining

- Degumming: Removes phospholipids.

- Bleaching: Adsorbs color pigments and impurities.

- Deodorization: Eliminates odors and free fatty acids.

- Fractionation (optional): Separates palm olein from palm stearin.

6. Palm Kernel Oil (PKO) Processing

- Kernel crushing, conditioning, and pressing or solvent extraction.

- PKO refining similar to palm oil refining.

7. By-Product Utilization

- Empty fruit bunches (EFB) for biomass energy.

- Palm fiber and shells as boiler fuel.

- Palm kernel cake (PKC) as animal feed.

Key Features of Huatai Palm Oil Lines

- High Oil Yield: Advanced pressing and extraction technologies maximize recovery.

- Energy Efficiency: Heat recovery systems and optimized processes reduce energy consumption.

- Automation: PLC-based control systems enable stable, low-labor operation.

- Environmental Compliance: Designed to meet international environmental and safety standards.

- Scalability: Lines available from 1 TPH small mills to 120 TPH industrial plants.

_副本.jpg)

Equipment Highlights

- Sterilizers: Fully insulated, automated steam control.

- Double-Screw Presses: Patented hydraulic screw design for superior performance.

- Threshers & Digesters: Robust construction for continuous operation.

- Refining Systems: Continuous or batch options, customizable to client needs.

- Kernel Recovery Plants: Efficient separation and processing systems.

Customized Solutions for Every Client

Huatai works closely with clients to design plants tailored to:

- Local FFB quality and supply

- Desired end products (CPO, RBD palm oil, palm olein, stearin, PKO)

- Available space, utilities, and environmental regulations

- Budget and ROI expectations

Global Success Stories

Huatai palm oil plants operate successfully across Southeast Asia, Africa, and Latin America

Why Choose Huatai for Your Palm Oil Plant?

- 38+ Years of Expertise: Proven engineering and project execution.

- End-to-End Service: From feasibility studies to commissioning and training.

- Innovation Focus: Continuous R&D in collaboration with industry research centers.

- Global Support Network: Technical assistance and spare parts available worldwide.

Whether you are establishing a new palm oil mill, expanding capacity, or modernizing an existing facility, Huatai delivers reliable, efficient, and sustainable processing solutions. Our complete palm oil lines are engineered to maximize profitability while maintaining high product quality and environmental responsibility.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

_副本.jpg)