According to the different pretreatment and pressing processes of the oil, the screw pressing method can be divided into hot pressing and low-temperature pressing. Hot pressing is to pre-treat the oil before pressing, such as steaming, frying, etc. The temperature during pressing is usually higher than 100℃. During the processing, the oil is in a high temperature state for a long time, which may cause some nutrients in the oil to be destroyed, but hot pressing has a high oil yield and fast production efficiency. Hot pressing is often used to produce fragrant peanut oil and rapeseed oil.

Low-temperature pressing is a process in which the oil without high-temperature pretreatment is directly fed into the oil press, and the low temperature state is continuously maintained during the pressing process to obtain oil and cake. Compared with the hot pressing method, the low-temperature pressing method avoids the free fatty acids and peroxides that may be harmful to the human body when the oil is in a high temperature state, thereby avoiding the mushy smell in the oil. The finished oil has a bright color and can retain more beneficial nutrients in the oil. The processing of oils such as tea seeds and walnuts is usually carried out by low-temperature cold pressing.

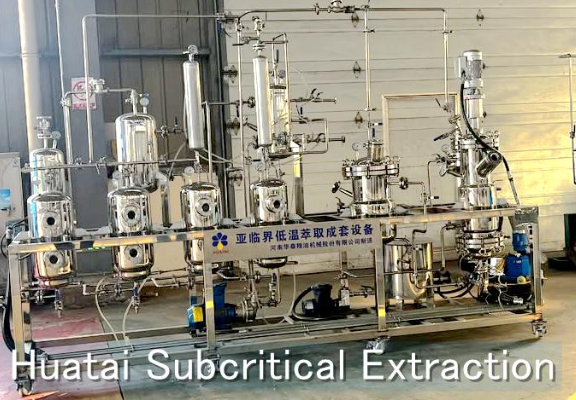

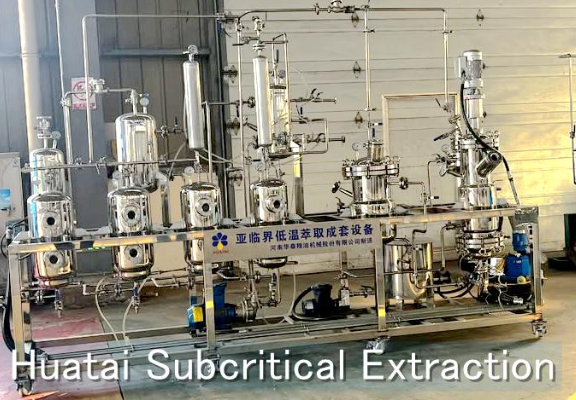

Flaking Thickness: 0.3-0.4mm

Flaking Moisture: <8%

Times of Butane Solvent Extraction: 4 times

Extraction Pressure:0.35-0.4mpa

Extraction Temperature: 25-35℃

Dissolution Ratio:1:1.2

Meal Residue:<1.5%

Cyperus Subcritical Extraction Plant | Henan Huatai Group

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

According to the different pretreatment and pressing processes of the oil, the screw pressing method can be divided into hot pressing and low-temperature pressing. Hot pressing is to pre-treat the oil before pressing, such as steaming, frying, etc. The temperature during pressing is usually higher than 100℃. During the processing, the oil is in a high temperature state for a long time, which may cause some nutrients in the oil to be destroyed, but hot pressing has a high oil yield and fast production efficiency. Hot pressing is often used to produce fragrant peanut oil and rapeseed oil.

According to the different pretreatment and pressing processes of the oil, the screw pressing method can be divided into hot pressing and low-temperature pressing. Hot pressing is to pre-treat the oil before pressing, such as steaming, frying, etc. The temperature during pressing is usually higher than 100℃. During the processing, the oil is in a high temperature state for a long time, which may cause some nutrients in the oil to be destroyed, but hot pressing has a high oil yield and fast production efficiency. Hot pressing is often used to produce fragrant peanut oil and rapeseed oil.