Introduction

Avocado oil, also known as avocado oil, is derived from the fruit of dried avocados and produced through oil extraction process to create a edible oil suitable for direct eat.

Avocados are cultivated worldwide in tropical and subtropical regions, with their origin in Mexico and Central America. Currently, the largest producers are the southern United States, Guatemala, Mexico, and Cuba.

In this article, I will introduce you to the complete process of avocado oil extraction and the costs involved in investing in an avocado oil processing plant.

Avocado Pretreatment: Peeling and Pitting

Peeling and pitting avocados determine oil yield and oil quality. They require rapid disruption of avocado cellular structure while also preventing oxidation.

Avocado Peeling and Pitting Machine

First, a flexible blade separates fruit flesh from pit. Then, a metal detector removes impurities, preventing damage to subsequent equipment.

Henan Huatai Group's patented spiral advancement design process technology (Patent No. CN116181874A) achieve avocado flesh damage rate of <3% while preserving integrity of flesh.

Grinding System

Grind the avocado flesh to a particle size of below 50 μm, use high-speed shear force (15,000 rpm) completely break down cell walls and release oils.

This time, the temperature control system maintains a grinding temperature ≤25°C to prevent activation of polyphenol oxidase.

Enzymatic Hydrolysis Reactor (Optional)

By adding pectinase/cellulase (ratio 0.01%-0.015%), hydrolyze at 40°C for 2 hours to break down the pectin network structure and release oils.

Suitable for unripe avocados with high pectin content, increasing oil yield by 12%-15%.

3 Methods of Avocado Oil Extraction

Ultrasonic-Assisted Cold Pressing

The ultrasonic-assisted cold pressing is preferred choice for producing high-quality avocado oil. The equipment used includes:

- Ultrasonic pretreatment tower: 300-320kHz acoustic frequencies cavitate residual cellular structures, forming microporous channels.

- Double-screw press: Low-pressure slow pressing (pressure ≤ 10 MPa) to avoid high temperatures causing chlorophyll degradation.

The advantage of this method is that avocado oil produced is bright green color with tocopherol retention rate of >98%, meeting organic certification standards.

![Cold pressed avocado oil extraction machine Cold pressed avocado oil extraction machine]()

Subcritical Butane Extraction

The low-temperature subcritical butane extraction method achieves the highest extraction rate. The equipment used includes:

Henan Huatai Group's patented extraction tank (CN117701332A): penetrates the fruit fresh with n-butane solvent at 40-50°C and 1.0-1.2 MPa subcritical pressure to dissolve avocado oil.

Three-stage counter-current extraction system: Fresh solvent - secondary mixed oil - primary mixed oil gradient oil extraction, reduce solvent consumption by 40%.

The subcritical butane low-temperature extraction method achieves avocado crude oil solvent below <5 ppm, and resulting low-temperature meal (protein denaturation rate <3%) can be processed into feed.

![Subcritical low-temperature extraction of avocado oil Subcritical low-temperature extraction of avocado oil]()

Supercritical CO₂ Extraction

Avocado oil extracted using supercritical CO₂ extraction is suitable for pharmaceutical-grade essential oils.

Under conditions of 35 MPa and 45°C, CO₂ selectively extracts sterol compounds.

Henan Huatai Group's patented coupled ultrasonic pretreatment technology reduces extraction time to one-third of traditional methods.

![Avocado oil refinery plant for sale Avocado oil refinery plant for sale]()

Avocado Oil Refinery Process

Because avocado oil is easily emulsified and has low saponification value, refining is necessary. The equipment used includes:

Three-phase centrifugal separator

The LWS430 centrifuge (separation factor 3000g) continuously separates oil, water, and solids, achieving an impurity removal efficiency of over 99.5%.

Huatai Group uses variable frequency control to adjust the disc gap, making it more suitable for avocado oil.

Molecular distillation tower

Under negative pressure of 2600-3097 Pa, free fatty acids are removed to prevent pigment degradation caused by high temperatures.

Key indicators: acid value (KOH) ≤ 0.3 mg/g, peroxide value < 2 meq/kg.

Low-temperature crystallization dewaxing system

Slow cooling at 4°C for 24 hours. Filtration using diatomaceous earth removes high-melting-point wax esters (accounting for 70% of impurities).

Solvent Recovery and Recycling System

Henan Huatai Group offers a closed-loop recovery solution to address solvent loss in subcritical extraction processes:

- Compressor Condensation Unit: Butane gas undergoes two-stage compression (coefficient of performance (COP) ≥ 4.5), achieving a condensation liquefaction rate > 99.8%.

- Vacuum Desorption Tower: Residual solvent in meal is reduced to below 300 ppm, meeting feed safety standards.

- Economic Efficiency: Solvent replenishment is less than 1.5 kg/ton of raw material, 35% lower than industry average.

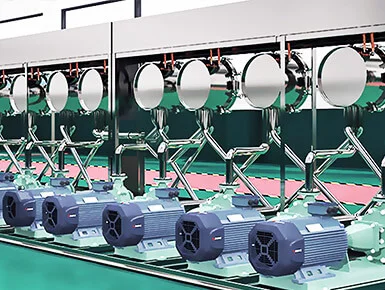

![Avocado oil processing plant Avocado oil processing plant]()

Cost of Setting Up an Avocado Oil Processing Plant

| Project Scale |

Hourly Raw Material Processing |

Equipment Investment |

Payback Period |

Gross Profit Margin |

| Small |

5 tons |

$389,706 |

14-18 months |

45% |

| Medium |

20 tons |

$1,280,463 |

22-26 months |

52% |

| Large |

50 tons |

$2,922,796 |

28-32 months |

58% |

Henan Huatai Intelligent Equipment Group provides EPC construction services for establishing commercial avocado oil production lines, including full-cycle services from material testing - process design - equipment installation - technician training, ensuring customers can quickly start production and generate profits.

Conclusion

Henan Huatai Intelligent Equipment Group manufactures avocado oil extraction and cold-pressing technology and equipment. This technology preserves natural nutrients in avocados and increases oil yield, and have been well received by users both domestically and internationally!

If you are considering purchasing an avocado oil extraction machine or are interested in investing avocado oil production industry, Henan Huatai Group can provide you with the best equipment and most professional services.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ