Introduction

Peanut oil, a widely favored cooking oil variety among consumers, enjoys steadily growing market demand. Investing in peanut oil extraction machine offers promising market prospects and investment returns.

Based on extraction principles, peanut oil production mainly divides into pressing and solvent extraction. The pressing method is more popular in the market due to its natural physical properties, which better preserve the oil's inherent flavor and nutritional components.

Huatai Group Peanut Oil Press Machine

Henan Huatai Group's HTZY series screw oil press has a processing capacity ranging from 8 to 300t/d, and is used to press more than 20 kinds of oilseeds, such as peanuts, soybeans, sesame, rapeseed, flaxseed, cottonseed, sunflower seeds, etc. Feel free to contact us for more information about our oil pressing equipment.

| Processing Capacity(t/d) |

Residual oil rate(%) |

Power(kw) |

External dimensions(mm) |

| 260-300/100-130 t/d |

14-18/8-10% |

110/90 kw |

4100*2270*3850 mm |

| 140-160/40-60 t/d |

14-18/7-9% |

75/55 kw |

3705*1040*2800 mm |

| 40-50 t/d |

10-18% |

30 kw |

2900*1850*3640 mm |

| 20 t/d |

7% |

32-38 kw |

2670*1000*1726 mm |

| 8-10 t/d |

6-8% |

7.5 kw |

2270*970*1565 mm |

6 Steps Peanut Oil Production Process

The complete peanut oil processing involves six stages: raw material pretreatment, crushing and dehulling, flaking and cooking, pressing, crude oil filtering, and oil refining. Each stage has specific process requirements and dedicated equipment, which together form a complete peanut oil production line.

Raw Material Cleaning and Pretreatment

Before entering the processing stage, peanut raw materials must go through cleaning and pretreatment. This stage mainly uses cleaning screen and stone remover to remove impurities, dirt, stones, and metal fragments from peanuts.

These machines effectively separate impurities through a combination of vibrating screen and air separation principle, protecting subsequent equipment from damage.

Pretreated peanuts also need moisture adjustment. Drying equipment controls peanut moisture content to below 4%. This reduces moisture's negative impact on oil quality and creates favorable conditions for subsequent red skin removal.

Crushing and Dehulling

Pretreated peanuts need dehulling because substances in peanut skins affect oil taste and quality. This stage uses dehulling machine and crushing machine.

First, cool peanut kernels to room temperature, then use dehulling machine to remove red skins. Next, use crushing machine to break them into 3-5mm peanut particles. Crushed peanut particles increase surface area, improving pressing efficiency.

Research shows, control crushing particle size proves crucial for improving oil yield. Particles are too large result in incomplete oil extraction, and particles are too small easily cause gelatinization, affecting oil quality.

Rolling and Cooking

Crushed peanut particles need rolling and cooking treatment. Rolling machine uses roller to press peanut particles into thin flakes, destroying cell structure to facilitate oil release.

Then, cooker heat-treat peanut flakes, typically maintaining 55-60°C, adding water to adjust flake moisture to 8-12%, and steaming for 15-20 minutes.

Precise temperature and humidity control during cooking is very important, directly affecting protein denaturation and increasing oil fluidity.

Oil Pressing

Pressing is the core stage of peanut oil extraction, mainly using screw oil press. Henan Huatai Group's large screw oil press maintains working temperatures of 45-50°C, extracting oil from peanut flakes through mechanical pressure.

Screw oil presses work by using rotating screw shafts to push materials forward. The space gradually decreases, generating enormous pressure that separates oil from peanut flakes.

This equipment features large processing capacity, low power consumption, and low operating costs. The pressed cake maintains a loose but intact structure, allowing easy solvent penetration and low residual oil rates. Pressing produces two parts: preliminary pressed peanut oil and peanut meal.

![Peanut oil filter machine for Sale Peanut oil filter machine for Sale]()

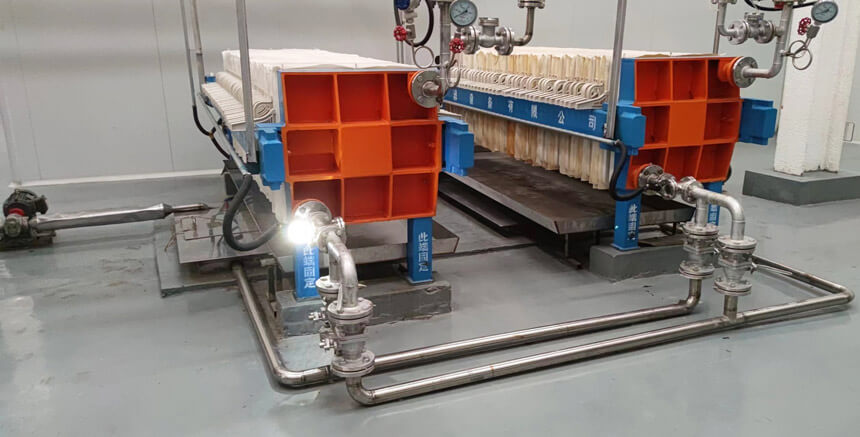

Crude Oil Filtering

Crude peanut oil from oil presses contains solid particles and impurities, need filtration and purification. This stage mainly uses centrifugal filter or vacuum filter, separating oil residue from oil through centrifugal force or vacuum negative pressure.

Modern filtering machines achieve continuous operation with automatic residue discharge, improving filtration efficiency. Filtered peanut oil becomes basically clear and can meet primary edible standards. However, achieving higher quality grades requires further refining.

Oil Refining

High-quality peanut oil needs refining treatment. Refining equipment includes degumming machine, deacidification machine, decolorization machine, and deodorization machine. (Related Product: Soybean oil refining machine >>)

The refining process removes free fatty acids, phospholipids, pigments, and off-flavor substances from oil, improving oil's smoke point, stability, and shelf life.

Small-scale refining equipment costs about $25,000, meeting the needs of small to medium-sized peanut oil processing plants. Refined peanut oil displays bright color, pure flavor, low acid value, and good stability, meeting national first-grade oil standards.

![Large-scale peanut oil production line Large-scale peanut oil production line]()

Henan Huatai Group Peanut Oil Extraction Projects

Henan Huatai Group possesses rich experience in peanut oil extraction projects, having constructed multiple projects with different scales and technical requirements. Here are three peanut oil extraction project cases completed by Huatai Group. (Related Video: Bolivia 1000TPD Soybean Oil Processing Plant >>)

50T/D Pressing, 20T/D Extraction, 20T/D Refining Peanut Oil Project

- Project Location: Ethiopia

- Processing Materials: Soybeans, peanuts, black seeds

- Processing Capacity: 50T/D pretreatment pressing, 20T/D extraction, 20T/D refining

- Project Features: Includes complete process of pretreatment, extraction, and refining. Features low cake residual oil (<0.5%), high oil yield, good meal quality, low production costs, and high automation levels.

10TPD Pressing, 3TPD Refining and Cold Filtering Peanut Oil Project

- Project Location: Anhui, China

- Processing Materials: Black soybeans, black peanut kernels

- Processing Capacity: 10TPD pressing, 3TPD refining, 3TPD cold filtering

- Project Features: Includes fragrant and cold pressing of black soybeans and black peanut kernels, plus subsequent refining and cold filtering.

10TPD Peanut Oil Extraction Project

- Project Location: Guangxi, China

- Processing Materials: Peanuts

- Processing Capacity: 10TPD

- Project Features: Fragrant peanut oil cold filtering and degumming project, with all indicators meeting contract agreements and national standards.

Huatai Group Peanut Oil Extraction Machine Features

High oil yield: Uses directional pressure bearing and multi-stage advancement technology. Oil yield increases 10-30% compared to conventional equipment, with each 100 kg of peanuts producing an additional 2-6 kg of oil on average.

Efficient energy saving: At the same output, power consumption reduces by about 40%. Equipment also strengthens the feeding system and increases advancement speed, improving work efficiency by over 30%.

High automation level: Features automatic temperature control (seed roasting and pressing chamber heating) and vacuum filtration (oil-residue separation). At the same output, it saves 60% of labor, typically needing only 1-2 operators, reducing labor costs and operational difficulty.

Multiple uses: Besides peanut, this equipment can also process sesame, rapeseed, soybeans, sunflower, cottonseed, flaxseed, and over twenty other oil crops, offering broad adaptability.

High oil quality: Vacuum filtration residues ensure pure oil meeting industry standards.

Durable construction: The machine body uses high-quality wear-resistant steel and anti-fatigue castings, providing stable performance for continuous long-term operation.

Advanced Technology: Has proprietary patented technology (such as automatic material level control drag chain extractor, Patent No.: ZL 2018 2 1882277.1), featuring new structure designed to reduce operational errors and improve production stability and oil yield.

How Much Does a Peanut Oil Press Machine Cost?

Peanut oil press machine prices depend on factors such as equipment scale, brand, model, and automation level, with costs ranging from tens of thousands to hundreds of thousands of dollars. As shown in the table below:

| Equipment Type |

Processing Capacity (tons/day) |

Price Range (USD) |

Core Equipment |

Application |

| Screw oil press |

5-10 t/d |

$4,200-$11,000 |

Single screw oil press machine |

Designed for customers to replace or upgrade existing production line equipment. |

| Small production line |

5-20 t/d |

$28,000-$70,000 |

Cleaning screen, steaming cooker, screw press, oil filter |

Suitable for family workshops, small oil mills, or start-ups. |

| Medium production line |

20-50 t/d |

$85,000-$140,000 |

Full set of pretreatment equipment, oil press, vacuum oil filter, simple refining equipment (degumming and deacidification) |

Suitable for medium-sized oil mills. |

| Large fully automatic production line |

50-200+ t/d |

$140,000-$280,000+ |

Fully automatic pretreatment equipment, oil press, full set of refining equipment (including degumming, deacidification, decolorization, and deodorization) |

Suitable for large oil and fat processing enterprises. |

| Refining Equipment Module (Add-on) |

/ |

$7,000-$42,000+ |

Deacidification, decolorization, and deodorization tanks, vacuum system, etc. |

As an add-on module to upgrade small and medium-sized production lines. |

Conclusion

Henan Huatai Intelligent Equipment Group, a leading company in the peanut oil industry, provides various models and configurations of equipment to meet different scales.

Huatai Group not only provides peanut oil processing machines but also offers comprehensive support in plant planning, equipment installation and commissioning, and operation training, helping you quickly achieve production and profitability. If you plan to invest in peanut oil extraction equipment or establish a peanut oil processing plant, please contact us anytime!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ