Introduction

A soybean oil processing plant extracts oil from soybeans through physical and chemical processes and refines it into edible oil. As global demand for vegetable oil grows (especially in Asian and North American markets), investing in soybean oil processing plants has become an industry with stable returns.

A complete soybean oil production line mainly includes raw material pretreatment, pressing/extraction, refining, and bottling. It can flexibly design production capacity according to investment scale, from small-scale (10 tons per day) to large-scale (over 100 tons per day).

Today, I will introduce the complete soybean oil production process, the machinery each step requires, and the costs of building different-scale soybean oil extraction plants.

![Soybean pretreatment process diagram Soybean pretreatment process diagram]()

Step 1: Soybean Pretreatment Section

Pretreatment directly affects soybean oil yield and quality, accounting for about 25-30% of the total processing energy consumption. This stage mainly includes cleaning, crushing, softening, flaking, and extruding.

Cleaning and Impurity Removal

Vibrating screens and magnetic separators remove impurities from soybeans. Vibrating screens separate large and small impurities through screen meshes, while magnetic separators remove metallic impurities.

- TQLZ series vibrating screen: Processing capacity 5-100 tons/hour with 2.2-7.5kW power. Features a double-layer screen design, the upper layer removes large impurities, and the lower layer removes smaller impurities.

- TQSF series gravity grading destoner: Processing capacity 1-14 tons/hour, removing sand, glass, and other impurities with higher specific gravity than soybeans.

- TXCT series magnetic separator: Uses neodymium iron boron strong magnetic materials with a magnetic field strength of ≥3000 Gauss, thoroughly removing ferrous impurities.

Small cleaning equipment costs about $1,400-$4,300, while large automated equipment costs $7,100-$14,300.

Crushing and Peeling

Crushers break whole soybeans into 4-6 pieces, increasing surface area and improving subsequent cooking efficiency. Peeling reduces pigments and bitter substances enter the oil.

PSP series toothed roll crusher: Roll diameter 400-800mm, processing capacity 10-100 tons/hour, achieving ≥95% rate of 4-6 pieces after crushing. Price ranges from $7,000-$14,500.

BF series separation system: Uses air separation principles with ≥85% separation efficiency and ≤5% hull content. Price ranges from $5,500-$10,500.

Softening and Conditioning

Softening cookers adjust soybean moisture and temperature through steam (typically heating to 60-70℃), increasing plasticity for easier flaking. Equipment typically uses stainless steel materials to ensure contamination-free processing.

WRHG series softening steam cooker: 3-5 layers, processing capacity 80-1000t/h, diameter 1200-2500mm, using indirect steam heating.

Flaking

Flaking uses mechanical external force to press crushed and softened soybean particles into thin flakes, destroying soybean cell structure and increasing surface area.

Flake thickness ranges from 0.25 to 0.30mm, appearing thin and uniform with no oil stains on the surface.

YYPT series flaking machine: Roll diameter 600-1000mm, roll length 800-1500mm, linear speed 2.5-3.0m/s, capacity 40-300 tons/hour. Price ranges from $21,400-$35,700.

Soybean Extrusion

Extrusion equipment uses mechanical extrusion and instantaneous decompression to thoroughly destroy soybean embryo tissue, forming porous expanded particles. Extrusion improves soybean extraction efficiency, reduces production energy consumption, and improves the value of by-product soybean meal.

Soybean extruder machine divide into dry and wet extruders. Dry-type extruders cost $15,000-$25,000, while wet-type extruders cost $35,000-$65,000.

Henan Huatai Group's extruders typically include conditioners, expansion chambers, and cutting devices, using special alloy screw wear-resistant materials with service life exceeding 8,000 hours.

![Soybean extruder machine for sale Soybean extruder machine for sale]()

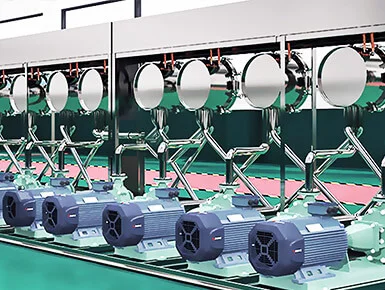

Step 2: Pressing and Extraction Section

Pressing and extraction are the core processes for extracting oil from processed soybeans, deciding the production line oil yield. You can choose physical pressing or chemical extraction based on investment scale.

Pressing Section

Screw oil presses are the core equipment in pressing section, extracting crude oil from crushed and softened soybeans through mechanical compression. After pre-pressing, crude oil enters the filtration, and sends cake to the extraction section for further residual oil extraction.

HTZY series oil press: Press chamber diameter 120-200mm, temperature 120-130℃, main shaft speed 25-35rpm, processing capacity 20 tons/day, cake residual oil rate 7%.

Small screw oil presses cost about $2,900-$7,800, while large equipment costs $14,300-$42,900.

Pressing retains soybean original fragrance and more nutritional components (such as vitamin E), making it suitable for producing high-quality edible oil. The process is simple, convenient to operate, with relatively low investment requirements.

![Soybean oil extraction machine for sale Soybean oil extraction machine for sale]()

Extraction Section

Extraction: Uses solvent (typically n-hexane) to dissolve residual oil in cake meal (about 3%-5%), increasing oil yield to over 18%. Extraction produces mixed oil and wet meal.

- HTYJP series rotocel extractor: Processing capacity 100-500 tons/day, power 2.2-7.5 kW. Extraction equipment for over 30 tons costs about $75,000 or above.

- Wet meal desolventizing: Processes wet meal through desolventizing treatment, producing finished soybean meal (protein content ≥45%).

- DTDC desolventizer: Processing capacity 100-6000t/d, power 30-390kw, finished meal residual solvent ≤500ppm, moisture ≤12.0%, protein denaturation rate ≤15%.

- Solvent recovery: Recovers solvent and separates crude oil from mixed oil. Solvent recovery rate must exceed 95% to reduce costs and safety risks.

- HTDQT series stripping tower: Heat exchange area 2.8-18.8㎡, outlet concentration ≥99.5%, temperature 115-120℃.

Many modern plants use combined pre-pressing and extraction processes, first pressing to extract most oil (~18%). Then, using extraction methods to extract residual oil from cake meal, increasing the total oil yield to over 99%.

![Soybean oil refinery plant Soybean oil refinery plant]()

Step 3: Refining Section

Crude soybean oil contains phospholipids, free fatty acids, pigments, and other impurities. The refining section aims to improve oil grade and stability, making it meet edible standards. This includes: degumming, deacidification, decolorization, and deodorization. (Related Post: Soybean oil refining machine >>)

- Degumming tank: Adds water or phosphoric acid to remove phospholipids (hydration degumming). The equipment uses stainless steel materials with stirring and heating functions.

- Deacidification tank: Adds alkali solution (NaOH) to neutralize free fatty acids, generating separated soapstock. During alkali refining, typically add 20-30Be alkali solution within 5-10 minutes and stir at 60r/min for 5-10 minutes, check soap particle formation and separation conditions after reaction.

- Decolorization tower: Adds white clay or activated carbon (typically 2%-4% of oil volume) to absorb pigments, residual soap particles, and trace metals. Operates under vacuum conditions (vacuum degree ≥700mmHg) to prevent oxidation.

- Deodorization Tower: Distills under high temperature (220℃-240℃) and high vacuum (above 755mmHg) conditions to remove odorous substances and free fatty acids through direct steam distillation for 2-3 hours.

Refining equipment investment varies greatly due to scale differences: small refining equipment costs about $3,500-$9,500, medium-scale costs $14,000-$43,000, and large-scale costs $105,000 and above.

![Soybean oil filling and storage Soybean oil filling and storage]()

Step 4: Packaging and Storage Section

Refined finished soybean oil requires safe and hygienic packaging and storage for sale.

Oil storage tank: For short-term storage of refined oil. Made of stainless steel with nitrogen blanketing systems to prevent oxidation. Capacity design follows 1.5-2 times daily production.

Automated filling machine: Provides quantitative filling in various forms (bottling, drum packaging). Small plants can choose semi-automatic equipment ($6,500-$20,000), while large plants require fully automatic production lines ($35,000+), including labeling and coding functions.

Packaging equipment: Includes sealing machines, case packers, and palletizers to complete final product packaging.

Soybean Oil Processing Plant Investment Cost Analysis

Soybean oil processing plant investment costs vary according to scale, automation level, and product grade. The following table shows investment estimation cost comparisons for three common scales (including equipment, plant buildings, and basic supporting facilities).

| Investment Type |

Small (5-10 tons/day) |

Medium (20-100 tons/day) |

Large (100-200 tons/day) |

| Pretreatment equipment |

$4,300-$7,100 |

$14,300-$28,600 |

$42,900-71,500 |

| Pressing equipment |

$2,900-$8,500 |

$14,500-$43,500 |

$43,500-$75,500 |

| Extraction equipment |

/ |

$71,400-$150,000 |

$150,000-$285,700 |

| Refining equipment |

$6,500-$13,500 |

$13,500-$115,500 |

$115,500-$235,500 |

| Packaging equipment |

$1,500-$5,500 |

$12,000-$50,000 |

$50,000-$100,500 |

| Total equipment investment |

$15,200-$34,600 |

$125,700-$387,600 |

$401,900-$768,700 |

| Building and environmental protection |

$18,000-$49,000 |

$75,000-$145,000 |

$145,000-$386,000 |

| Working capital |

$30,000-$75,000 |

$143,000-$286,000 |

$286,000-$571,000 |

| Total investment estimate |

$63,200-$158,600 |

$343,700-$818,600 |

$832,900-$1,725,700 |

| Features |

Suitable for start-ups, with an oil yield of about 16%-18%, mainly producing second-grade or crude oil. |

Suitable for regional businesses, with an oil yield of 18%-20%, capable of producing first-grade oil, and a high degree of automation. |

Suitable for large-scale enterprises, with products covering from first-grade oil to salad oil and specialty oils, and an oil yield of more than 20%. The by-product soybean meal can be sold for revenue generation. |

Please note: Final investment amounts will vary significantly due to different technical solutions, configuration choices, geographic locations, and local policies. For example, automated production lines require a higher initial investment but can reduce energy consumption and labor costs by 15%.

Conclusion

Henan Huatai Intelligent Equipment Group, as a manufacturer and exporter of soybean oil extraction machinery, can provide complete solutions according to specific customer needs, from single equipment to complete turnkey plant projects, including comprehensive services such as process design, equipment manufacturing, installation and commissioning, and technical training.

If you want to learn more about soybean oil processing plant costs or start a soybean oil processing business, feel free to contact us anytime!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ

(1)大豆竖版-封面.jpg)

膨化机介绍-封面_副本.jpg)