Introduction

Peanut oil is one of the most popular traditional cooking oils among consumers. Its production process involves two methods: mechanical pressing and solvent extraction. Mechanical pressing can extract 70%-80% of the oil from peanuts; solvent extraction extracts the remaining oil.

Below, you'll find the detailed peanut oil production process, which combines mechanical pressing and solvent extraction for a complete process. (Related Solution: Peanut oil production line >>)

Step 1: Dehulling

Peanut shells absorb oil readily despite containing no oil themselves. Removing the shells reduces oil absorption by the shells and reduces wear on the oil pressing equipment.

Step 2: Cleaning

Use vibrating screens, magnetic separators, and destoners to remove impurities such as soil, dust, broken shells, and rust from the peanuts. This ensures clean raw materials for processing.

![Seeds cleaning vibrating screen Seeds cleaning vibrating screen]()

Step 3: Crushing

Since peanuts are relatively large, they heat unevenly during processing. Ensure uniform steam cooking in the subsequent stage, need to crush the peanuts into evenly-sized particles or powder.

The crushing degree depends on the pressing equipment and process requirements—the material shouldn't be too fine or too coarse.

Step 4: Flaking

To further break down the internal cellular structure of the peanuts and increase their surface area for pressing, use a flaking machine to compress the peanuts into uniformly thick flakes.

Step 5: Cooking

Cooking the peanuts at 130–150°C for 30–60 minutes, controlling moisture content and temperature.

Cooking denatures proteins and makes oil separation easier, preparing the peanuts for optimal pressing conditions. It also removes raw flavors and enhances the peanut oil's aroma.

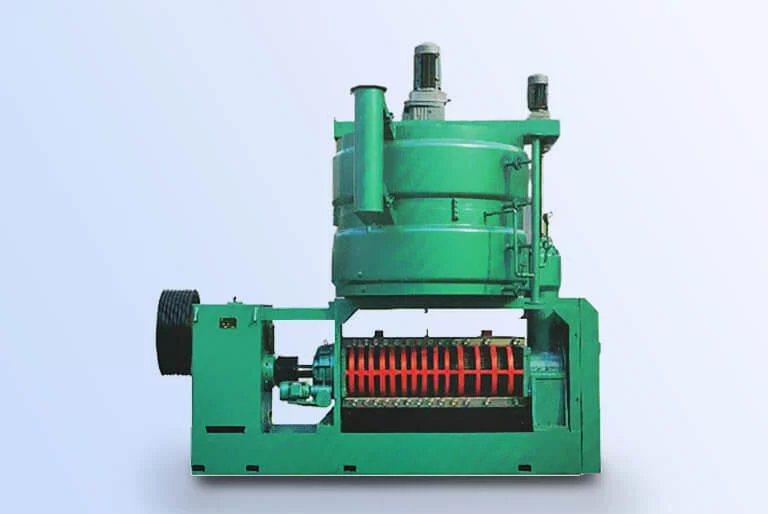

![Huatai Group 32 screw oil press Huatai Group 32 screw oil press]()

Step 6: Pressing

Feed the steamed peanut kernels into the peanut oil press, and use physical pressing methods. The screw press and peanut kernels create continuous pressure and friction in the pressing chamber, extracting peanut oil from the kernels to produce crude peanut oil and peanut cake.

The crude peanut oil (about 70%-80%) retains the peanuts' original rich aroma and more nutritional components. After refining, can sell it directly to the market.

The peanut cake still contains about 12%-18% residual oil. Use hexane to repeatedly spray and soak the cake, dissolving the residual oil. After solvent extraction, the oil content in the peanut cake drops to less than 1%.

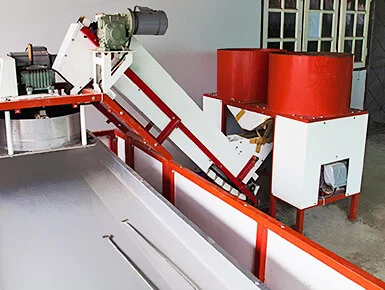

Step 7: Filtration

TThe pressed crude peanut oil contains residue and incompletely removed impurities. Filtration equipment (such as plate-and-frame filters) filter the peanut oil. Multiple filtration improves the filtration effect.

![Peanut oil refining process Peanut oil refining process]()

Step 8: Refining

Crude peanut oil from pressing or extraction contains impurities and needs further refining to meet edible standards. Refining includes these steps:

- Degumming: Add food-grade phosphoric acid at a specific concentration to crude peanut oil removes gums.

- Deacidification: Peanuts naturally contain free fatty acids that affect the oil's flavor. Adding NaOH removes these free fatty acids from the peanut oil.

- Decolorization: Hot-pressed peanut oil is typically darker due to high-temperature heating. Decolorization makes the crude oil clearer and lighter. The process usually uses physical decolorants, such as activated clay, which absorb pigments from the oil.

- Deodorization: Processing through various heated mechanical equipment creates odorous small molecules that affect the oil's flavor and taste. High-temperature heating under vacuum conditions strips these odor molecules from the peanut oil.

However, refining may cause some loss of nutritional components and flavor changes in the peanut oil. Consumers who prefer natural, pure peanut oil can choose unrefined options.

Step 9: Storage

Store refined peanut oil in clean, sealed containers in a cool, dry, well-ventilated area, away from direct sunlight and high temperatures to prevent spoilage.

Conclusion

In conclusion, peanut oil production process is a continuous workflow: peanut treatment, oil pressing, residual oil solvent extraction, oil filtration, and refining.

Henan Huatai Intelligent Equipment Group, a professional oil equipment manufacturer with 37 years of experience, provides customers with complete solutions from equipment manufacturing to factory construction guidance. If you want to learn more about peanut oil extraction equipment, please feel free to contact us anytime!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ