Introduction

Sunflower oil refining removes gums, free fatty acids, pigments, off-flavors, and waxes from crude oil while preserving natural nutrients (such as vitamin E) and flavor compounds to the maximum. The entire process involves continuous physical and chemical treatments.

In this guide, I will introduce you to the crude sunflower oil refining process, the equipment used, the differences between refined and crude sunflower oil, and the costs of setting up a sunflower oil refinery plant.

What Are Steps in Crude Sunflower Oil Refining Process?

The crude sunflower oil refining process includes five steps: degumming, deacidification, decolorization, deodorization, and dewaxing (optional). (Watch Our Video: Large-scale sunflower oil production line in Kazakhstan >>)

Step 1: Degumming

Degumming removes water-soluble phospholipids (such as lecithin) and non-water-soluble phospholipids from crude oil. These substances darken the oil color, create foam and sediment, and affect oil stability and appearance.

The process adds hot water or dilute acid (such as phosphoric acid) to crude oil, causing phospholipids to absorb water, swell, and agglomerate. Then use a centrifuge to separate them. Degumming divides into two methods:

- Water degumming: Suitable for crude oil with high phospholipid content and good quality.

- Acid degumming: Treats difficult non-hydratable phospholipids more effectively.

Huatai Group's degumming equipment uses corrosion-resistant materials and precisely controls water temperature, water addition, and stirring intensity to ensure thorough phospholipid hydration. The system accurately measures acid addition for thorough degumming.

Step 2: Deacidification/Neutralization

Crude sunflower oil contains free fatty acids that create a pungent taste, promote oxidation and rancidity, and reduce shelf life. Therefore, deacidification is necessary.

Deacidification mainly uses chemical alkali refining. The process adds a measured amount of sodium hydroxide solution to degummed oil. Neutralizes free fatty acids and forms soapstock. Finally, a centrifuge separates the soapstock from the oil. The soapstock can produce soap or fatty acids.

Huatai Group's automated control system calculates and adds alkali precisely based on real-time acid values, maximizing oil yield.

![Sunflower oil refining process flow chart Sunflower oil refining process flow chart]()

Step 3: Decolorization/Bleaching

Decolorization removes pigments from oil (such as chlorophyll and carotenoids) while adsorbing residual gums, soap particles, and metal ions.

Under vacuum and heating conditions, add adsorbents (usually activated white clay) to the oil. The clay's strong adsorption properties remove pigments and other impurities, then a filter separates the spent clay from the oil.

Huatai Group's decolorization towers prevent oil oxidation during heating and ensure oil freshness. Our automated clay dosing systems and efficient vertical leaf filters ensure stable decolorization effects, thorough filtration, and reduced labor intensity.

Step 4: Deodorization

Deodorization is the key step in crude sunflower oil refining. It removes volatile compounds causing off-flavors (such as aldehydes and ketones), residual free fatty acids, and peroxides, resulting in oil with a stable, mild flavor.

The process uses high temperature, high vacuum, and direct steam stripping principles. Under high vacuum, the oil's boiling point decreases. Steam injection removes off-flavor compounds and volatiles from the oil.

This produces premium refined sunflower oil with pure flavor, clear transparency, and stable quality, meeting Grade 1 oil standards.

Tips: Adding a small amount of citric acid before deodorization improves the oil's oxidation stability and extends shelf life.

![Edible oil deodorization tower Edible oil deodorization tower]()

Step 5: Dewaxing (Optional)

Hot-pressed sunflower oil contains high-melting-point waxes. These waxes crystallize at low temperatures, causing the oil to become cloudy and affecting its appearance. Therefore, dewaxing is necessary.

First, through slow cooling, waxes crystallize and precipitate. Then crystallization tanks and winterization filters (such as belt filters or plate-and-frame filters) separate the wax crystals from the oil.

If you are finished sunflower oil primarily targets retail markets with high appearance requirements or serves cold dish preparation, dewaxing is very important.

Huatai Group offers various dewaxing solutions. You can select the most suitable equipment based on your production capacity and budget, ensuring efficient filtration and high oil yield.

What Are Factors Affect Sunflower Oil Refinery Effect?

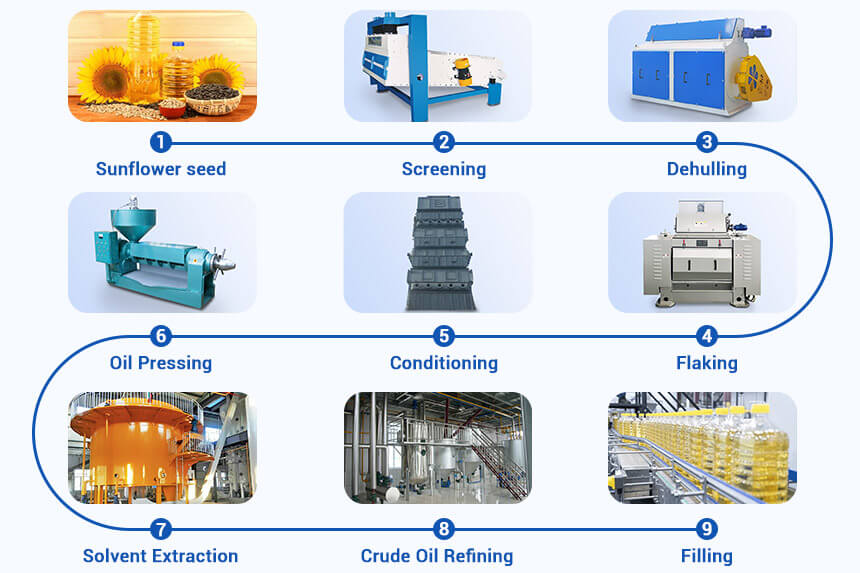

- Initial crude oil quality: If pretreatment dehulling is incomplete, the crude oil will contain high wax content, increasing the dewaxing section burden and losses.

- Crude oil storage conditions: If crude oil contacts air, light, or high temperatures during storage, oxidation accelerates, acid values increase, and color deepens. This increases refining costs and affects the finished oil flavor and stability.

- During degumming: Insufficient water/acid volume or improper temperature may cause incomplete phospholipid hydration or coagulation; poor centrifuge separation causes gum residue.

- During deacidification: Excessive alkali or high concentration saponifies more neutral oil, causing oil yield to drop. Insufficient alkali causes incomplete deacidification, resulting in finished oil acid values exceeding standards.

- During decolorization: Since activated clays have different adsorption capacities, selection depends on the crude oil's pigment situation. Excessive use increases costs and oil loss, while insufficient use fails to meet decolorization standards.

- During deodorization: Improper temperature and time cause off-flavor compounds to be incompletely removed. Excessive temperature or time destroys natural nutrients in the oil (such as vitamin E) and produces trans fatty acids.

- During dewaxing: Rapid cooling produces fine wax crystals that are difficult to filter. Insufficient crystal growth time results in incomplete crystal formation, affecting filtration efficiency and causing oil turbidity.

![Sunflower oil refining machine for sale Sunflower oil refining machine for sale]()

What Equipments Are Used in Sunflower Oil Refining?

The sunflower oil refining process is a continuous system. Below are the core equipment for each stage. (Related Product: Edible oil refining equipment >>)

Acid/Alkali Reaction Tank (with stirring)

This sealed vessel features stirring equipment and a jacket (for heating and insulation). Here, first add phosphoric acid (or citric acid) for acid degumming, then add precisely metered alkali solution for neutralization.

Huatai's equipment uses variable-frequency speed-controlled stirring, ensuring thorough acid/alkali mixing with oil while preventing excessive emulsification.

Centrifuge

Typically, a disc centrifuge. Its high-speed rotation generates powerful centrifugal force, enabling continuous and efficient separation of light phases (refined oil) and heavy phases (soapstock/gums) with differing densities.

Huatai Group provides self-cleaning disc centrifuges that can set discharge cycles without stopping for cleaning, improving continuous production efficiency and stability.

Decolorization Tower (Vacuum Decolorization Tank)

Deacidified oil enters the decolorization tower under vacuum and mixes with precisely metered activated white clay, stirring at specific temperatures (usually 105-110°C) under vacuum for a set time.

The vacuum environment removes air and moisture from oil, preventing oxidation during heating.

Filter

Filters completely separate spent clay from oil after decolorization. Two common types include:

- Vertical leaf filter: Features a large filtration area and high automation. Uses nitrogen or compressed air backflushing for residue removal, with low labor intensity and good filtration effect.

- Plate-and-frame filter: Suitable for small batches or special oils, but requires high labor intensity and easily causes oil exposure to oxidation.

For large-scale sunflower oil processing plants, vertical leaf filters can ensure no clay powder residues in the oil.

Deodorization Tower

The deodorization tower integrates heat exchange, stripping, and cooling in a large high-vacuum tower. Modern continuous deodorization towers typically divide into multiple functional zones:

- Degassing/preheating zone: Removes dissolved oxygen from oil.

- Heating zone: Uses high-temperature thermal oil to heat oil to high temperatures (typically 230-260°C).

- Deodorization zone: Introduces direct steam for stripping under high temperature and vacuum to remove odorous substances and free fatty acids.

- Heat recovery zone: Uses hot oil to heat incoming cold oil, significantly reducing steam consumption—a key energy-saving feature.

- Cooling zone: Cools finished oil under vacuum to safe storage temperature (typically below 60°C).

Crystallization Tank

By circulating cooling medium (such as cooling water or chilled brine) through the jacket, the oil temperature slowly decreases according to preset curves, promoting wax crystallization and full growth.

Winterization Filter

Winterization filters separate wax crystals from oil. Two common types include:

- Belt vacuum filter: Suitable for large-scale continuous production with high automation and excellent filtration effect.

- Plate-and-frame filter: Suitable for small to medium scale or batch production with lower investment costs.

What Is the Difference Between Refined Sunflower Oil and Crude Sunflower Oil?

| Features |

Crude Sunflower Oil |

Refined Sunflower Oil |

| Appearance and Color |

Deep amber or greenish-yellow, maybe cloudy and unclear |

Clear and transparent, bright pale yellow color |

| Odor and Flavor |

Intense roasted-nutty aroma, pronounced flavor |

Mild, delicate aroma, nearly odorless |

| Smoke Point |

Lower (around 107°C / 225°F) |

Very high (> 220°C / 430°F) |

| Low-Temperature Stability |

Significant flocculent sedimentation or solidification occurs after refrigeration |

Maintains clarity even at low temperatures |

| Free Fatty Acid Content |

Higher (high acid value) |

Extremely low (acid value ≤0.6mg KOH/g) |

| Nutritional Content |

Poorer. Prone to spoilage due to pro-oxidant components like phospholipids and pigments |

Good. Most pro-oxidant impurities removed |

| Oxidation Stability |

Retains more “natural” components: Vitamin E, phytosterols, carotenoids, etc |

Retains most vitamin E and phytosterols, though some heat-sensitive nutrients are lost during high-temperature deodorization |

What Is Setup a Sunflower Oil Refinery Plant Cost?

The cost of setting up a sunflower oil refinery plant depends on multiple factors, such as production scale and automation level, processing technology, equipment quality and suppliers, and factory buildings and infrastructure. The table below shows costs for different-scale sunflower oil refining plant (excluding factory buildings and infrastructure):

| Plant Scale |

Production Capacity |

Investment Cost |

Features |

| Small-scale |

1-10 ton/day |

$41,000 - $110,000 |

Includes cleaning and screening, shelling, oil extraction, filtration, and basic refining equipment. |

| Medium-scale |

10-50 ton/day |

$110,000 - $276,000 |

A complete sunflower oil production line, including cleaning machines, hulling machines, steaming cooker, oil press, filtration, refining equipment, and supporting electrical control systems. |

| Large-scale |

50-100 ton/day |

$276,000 - $552,000 |

Featuring high-end configurations for fully automated, continuous production, including cleaning and screening equipment, hulling machines, crushers, steaming cooker, screw oil presses, oil filters, and continuous refining equipment. |

Conclusion

In summary, the sunflower oil refining process is a systematic engineering, each step directly affects the final oil quality, cost, and market competitiveness. Choosing an experienced sunflower seed oil equipment manufacturer is key to your success.

Henan Huatai Intelligent Equipment Group not only provides complete sunflower oil refining equipment but also leverages 37 years of project experience to ensure your sunflower oil refinery operates at optimal conditions from the first day of production, producing high-quality sunflower oil with strong market competitiveness.

If you have specific crude sunflower oil specifications or plans, we can provide more targeted refining solutions and equipment selection recommendations. Feel free to consult us anytime!

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ