Introduction

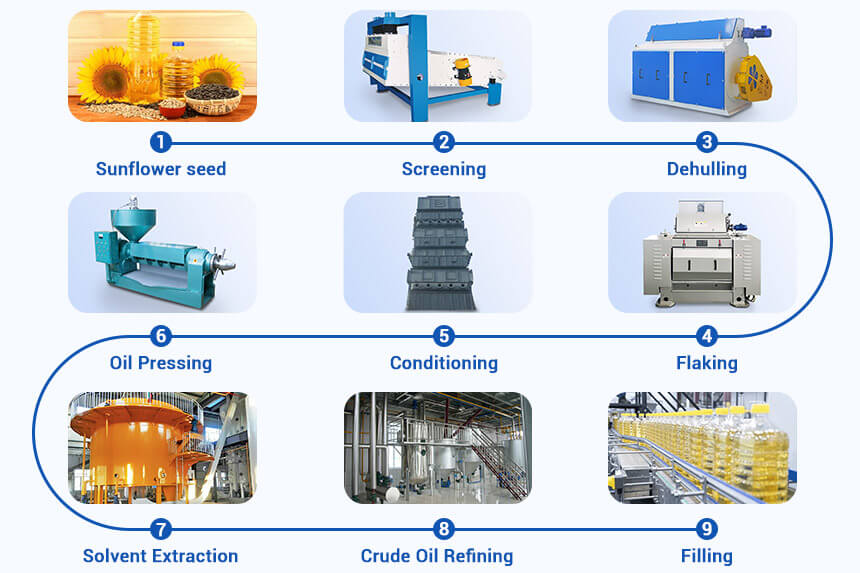

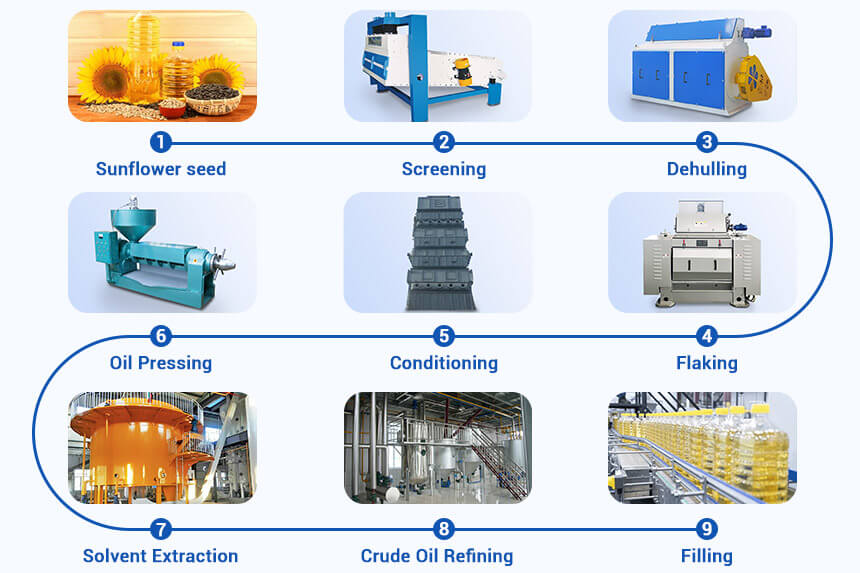

Sunflower seed oil processing plants convert sunflower seeds, rich in oil content (35%-50%), into edible oil meeting industry standards through a series of physical or chemical treatments. The sunflower oil production process consists of four main stages: seed pretreatment, oil pressing, solvent extraction of cake meal (optional), and crude oil refining.

Below, I will introduce the complete sunflower seed oil production process step by step, Henan Huatai Group's sunflower seed oil processing project cases, and analyze the sunflower oil industry market.

Sunflower Oil Processing Steps

Step 1: Cleaning and Impurity Removal

Sunflower seeds go through cleaning by vibrating screens and gravity destoners to remove sand, stones, metal, straw, and other contaminants. This step protects subsequent equipment from damage.

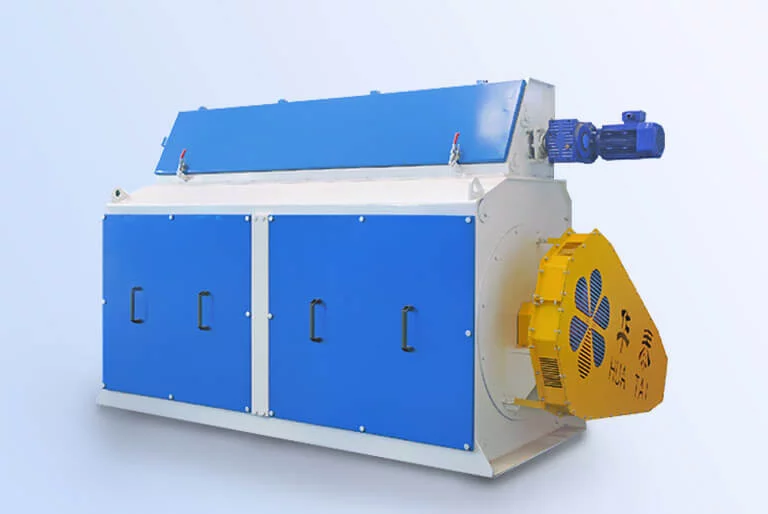

Step 2: Dehulling

Sunflower seeds have a high shell content. Shell removal effectively reduces oil absorption by shells, improves oil yield, and prevents pigments and waxes from shells from entering the oil.

A centrifugal shelling machine separates the shells from the kernels. Typically, the shell content in the separated kernels must be below 5%.

![Sunflower seed shelling machine Sunflower seed shelling machine]()

Step 3: Flaking

Feed hulled kernels into a flaking machine, which presses them into thin flakes measuring 0.3-0.5 mm thick. The flaking machine breaks down the oilseed's cellular structure and increases surface area, making oil extraction easier in after processes.

Step 4: Steaming and Conditioning

This is the key step in the hot pressing process. Send the flaked material into a steaming cooker, where steam conditions the flakes. By controlling temperature (98-110°C) and moisture content (reducing from 10-16% to 1-2%), proteins denature and oil viscosity decreases, facilitating pressing.

For cold pressing process prioritizing nutrient retention, you can skip this step or strictly control temperatures below 60°C.

Step 5: Oil Pressing

Feed the conditioned sunflower seed kernels into a screw oil press for extraction. The screw press generates continuous high pressure through the rotation of its screw shaft, squeezing oil out of the seeds.

The pressing process produces crude oil containing sediments and cake meal. Hot pressing achieves higher oil yields, while cold pressing better preserves the oil's natural flavor and nutrition.

![Sunflower oil solvent extraction plant Sunflower oil solvent extraction plant]()

Step 6: Cake Residue Solvent Extraction (Optional)

After pressing, the oil cake still contains about 6% residual oil. To fully extract economic value, large-scale sunflower oil processing plants add a solvent extraction section.

The process uses hexane to soak the pressed oil cake, dissolving the remaining oil. This section produces extracted crude oil and desolventized cake. The solvent-extracted crude oil joins the pressed crude oil for refining, while the desolventized meal serves as high-protein feed material.

![Crude sunflower oil refining process Crude sunflower oil refining process]()

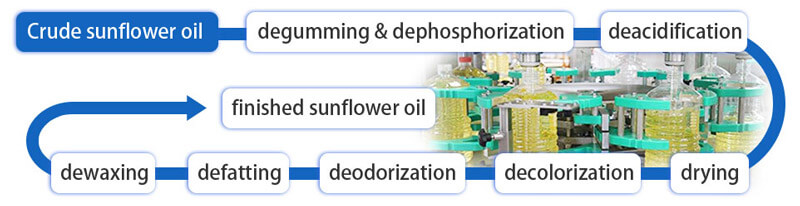

Step 7: Crude Oil Refining

Both pressed and solvent-extracted crude oil contain gums, free fatty acids, pigments, off-flavor substances, and waxes. It must go through refining to meet edible standards. (Related Solution: Edible oil refining >>)

First, use hydration or acid refining methods to remove phospholipids from the crude oil. Next, add alkaline solution to neutralize free fatty acids, forming soapstock that centrifugal separation removes.

Then, add activated clay to remove pigments from the crude oil. Finally, under high temperature and high vacuum conditions, use steam to volatilize off-flavor substances, aldehyde-ketone compounds, and residual free fatty acids from the crude oil.

When using cold pressing for sunflower oil, it contains small amounts of wax. The dewaxing process cools the oil to low temperatures (e.g., 6-12°C) to crystallize and precipitate the wax. Then, filtration removes these crystals.

Step 8: Filling and Storage

Package and store the refined sunflower oil for sale. Automated filling machines dispense oil into bottles, drums, or bags of various sizes, complete sealing and labeling.

Store the oil in light-proof, sealed conditions, using nitrogen-flushed tanks to prevent oxidation.

![Sunflower oil production plant Sunflower oil production plant]()

Sunflower Oil Processing Plant Project Cases

Henan Huatai Intelligent Equipment Group has extensive successful project experience domestically and internationally, particularly in Belt and Road Initiative countries. Here are our sunflower oil processing projects in Uzbekistan:

200 TPD sunflower, cottonseeds and soybeans oil processing plant:

- Raw Materials: Sunflower seeds, cotton seeds, soybeans

- Capacity: 200 TPD (tons per day)

- Project Features & Solutions: The high-low temperature mixed line design allows flexible selection of production processes based on raw materials and product requirements. The project succeeded on its first trial run, with both oil quality and protein content meeting customer expectations.

Sunflower and cottonseed oil 100 TPD pressing, 80 TPD extraction, 50 TPD refining plant:

- Raw Materials: Sunflower seeds, cotton seeds

- Capacity: 100 TPD oil pressing, 80 TPD extraction, 50 TPD refining

- Project Features & Solutions: Complete set of equipment export includes seed pretreatment, solvent extraction, refining, and dewaxing. Huatai Group maintains local offices and spare parts warehouses, providing robust after-sales support.

100 TPD sunflower oil production line:

- Raw Materials: Sunflower seeds

- Capacity: 100 TPD

- Project Features & Solutions: This project again demonstrates Huatai Group's competitiveness in the international market. From process design to manufacturing acceptance, all stages were completed to high standards, ensuring efficient and stable equipment operation.

Sunflower Oil Processing Market Analysis

The table below shows the latest sunflower oil production forecasts and trend analysis for major global producers, including Russia, Ukraine, the European Union, Argentina, Turkey, China, South Africa, Serbia, Kazakhstan, the United States, Myanmar, Moldova, Pakistan, and India:

| Country/Region |

Latest Production Data/Status |

Data Year/Type |

Trend & Remarks |

| Russia |

15.70 million tons (Sunflower oil production) |

2024/25 |

World's largest producer. Production decreased approx. 10% YoY due to drought. However, a record high is forecast for 2025/26. |

| Ukraine |

6.36 million tons (Sunflower oil production forecast) |

2025/26 |

World's second-largest producer and exporter. Forecast revised down from 6.55 million tons due to unfavorable weather. |

| European Union |

Production forecast revised down to 16.08 million tons (Total vegetable oil, includes sunflower oil) |

2025/26 |

Major producing region. Oilseed production forecasts have been successively revised down, though overall volume remains higher than the previous year. Sunflower seed production is forecast at 9.26 million tons. |

| Turkey |

Approx. 0.9 - 1.0 million tons |

2024/25 Estimate |

Important regional production and processing hub. Domestic production cannot meet large domestic consumption. Heavily reliant on imports from Russia and Ukraine for refining and re-export. |

| Argentina |

Approx. 0.8 - 0.9 million tons (historical average) |

2024/25 Estimate |

Major producer in South America. Production has fluctuated significantly in recent years due to domestic economic policies and drought, but its high-quality oil remains competitive on the international market. |

| China |

Approx. 0.6 - 0.7 million tons |

2024/25 Estimate |

One of the world's largest vegetable oil consumers, but relatively small sunflower oil producer. Domestic production falls far short of demand, making it a major importer, primarily from Russia and Ukraine. |

| United States |

Approx. 0.2 - 0.3 million tons |

2024/25 Estimate |

Main producer in North America. Production is relatively stable but much smaller in scale than soybean oil. Primarily for domestic niche markets and specific consumer demand. |

| India |

Approx. 0.15 - 0.25 million tons |

2024/25 Estimate |

One of the world's largest vegetable oil importers, but very low domestic sunflower oil production. Domestic consumption is highly dependent on imports, making it a key export market for Ukrainian and Russian sunflower oil. |

| Kazakhstan |

365.4 thousand tons (unrefined sunflower oil, Jan-Jul 2025) |

2025 (YTD cumulative) |

Emerging export power. Increased 24.9% YoY, with strong export growth. Has become a top-ten global exporter. |

| South Africa |

Approx. 0.1 - 0.2 million tons |

2024/25 Estimate |

Largest sunflower oil producer in Africa. Production mainly serves domestic and regional African markets, playing a key role in regional food security. |

| Serbia |

Approx. 0.1 - 0.15 million tons |

2024/25 Estimate |

Significant producer in the Balkan region. Like Moldova, it is a stable regional supply source. |

| Moldova |

Approx. 0.1 million tons |

2024/25 Estimate |

Important regional exporter. Despite its small size, sunflower oil is a significant agricultural export. |

| Myanmar |

< 0.1 million tons |

2024/25 Estimate |

Emerging small-scale producer. Production is growing, primarily for local and neighboring markets. |

| Pakistan |

< 0.1 million tons |

2024/25 Estimate |

Net importer. Domestic production is very low, serving as a supplement to local consumption. Significant demand is met through imports. |

Conclusion

The above is the complete sunflower oil production process, Henan Huatai Group's sunflower oil processing project cases, and the global sunflower oil industry market situation.

Sunflower oil processing includes multiple stages that determine the equipment and machinery required for sunflower oil processing plants. Equipment for small-scale sunflower seed oil processing plants may be relatively simple and easy to operate. If you are interested in sunflower seed oil processing, please contact us for more detailed information!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ