Introduction

Sunflower oil making machine, also known as fully automatic screw oil press or hydraulic oil press, mainly extracts oil from sunflower seed, rapeseed, soybean, peanut, cottonseed, and over 20 types of oilseeds.

Henan Huatai Group offers high-quality sunflower oil making machines in various capacities, ranging from 1 ton to 50 tons per day. With an outstanding reputation in the edible oil production industry, we provide the most suitable solutions for small and large-scale enterprises.

Two Main Methods for Making Sunflower Oil

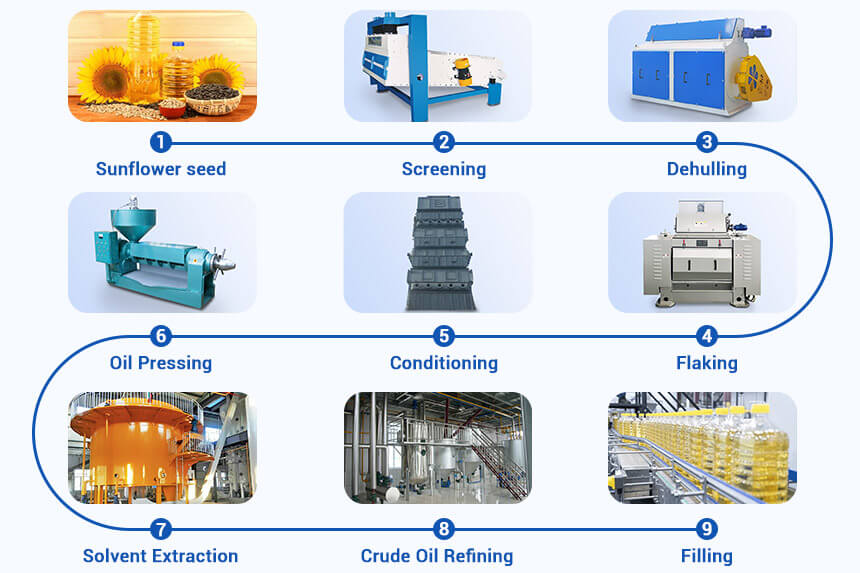

Sunflower oil production mainly involves two methods: physical pressing and solvent extraction. Each method has distinct principles and applications.

![Sunflower oil press machine for sale Sunflower oil press machine for sale]()

Physical Pressing Method

The physical pressing method uses mechanical force to squeeze oil directly from processed sunflower seed material. This method offers simple technology, requires fewer supporting equipment, adapts well to various oil varieties, and is flexible for production. The extracted sunflower oil has pure flavor, light color, and high quality. However, the cake residue retains more oil, has lower oil extraction efficiency, and higher energy consumption. (Read More about: sunflower seed oil production line >>)

Physical pressing divides into hot pressing and cold pressing:

Hot Pressing: Sunflower seeds go through steaming and roasting. High temperature destroys the oil cell structure, increases oil yield, and makes oil separation easier. The resulting crude oil has a darker color and requires further refining.

Hot pressing production process: Sunflower seeds → Shelling machine removes shells → Shell-kernel separation → Steaming cooker seeds → Oil press extraction → Filtration → Hot-pressed crude oil → Refining.

Cold Pressing: Sunflower seeds skip high-temperature treatment before pressing. This method better preserves natural flavor and nutritional components of sunflower oil and maintains lower oil extraction temperatures, but the oil yield is typically lower than hot pressing.

Cold pressing production process: Sunflower seeds → Shelling → Shell-kernel separation → Oil press extraction → Filtration → Cold-pressed oil → Refining. (Watch Video: Large-scale sunflower oil production line >>)

![Sunflower oil solvent extraction plant Sunflower oil solvent extraction plant]()

Solvent Extraction Method

The solvent extraction method uses hexane to dissolve and extract oil from oils, based on solid-liquid extraction principles. This method achieves very high oil yields, minimal residual oil in cake meal, low processing costs, and suits large-scale industrial production.

Solvent extraction requires significant initial investment. The solvents typically include flammable, explosive, and toxic substances, and stringent high production safety standards. The crude oil contains more non-fat components and dark color, requiring refining processes before eat.

The solvent extraction process generally includes pretreatment, pre-pressing, mixed oil evaporation and stripping, and solvent recovery. (Related Products: Edible oil solvent extraction equipment >>)

![Sunflower oil extraction machine structure Sunflower oil extraction machine structure]()

Sunflower Oil Press Machine Main Structure

For small-to-medium scale and traditional sunflower oil manufacturing plants, the screw oil press is currently the most widely used pressing equipment. It mainly consists of the following core components:

- Hopper: Receives and conveys sunflower seeds for awaiting pressing.

- Gearbox: Transfers power and controls the screw shaft rotation speed.

- Pressing chamber: The core cavity where pressing occurs, with press bars arranged inside to create a high-pressure space.

- Pressing screw: Also called the screw shaft, this key component squeezes oil from sunflower seeds. Its root diameter gradually increases while the pitch decreases, pushing forward and squeezing oil materials during rotation. Some models designed for high-oil-content materials adopt dual-screw shaft designs to enhance thrust.

- Frame: The structural framework supporting the entire equipment.

![Small scale sunflower oil mill plant Small scale sunflower oil mill plant]()

How Does Sunflower Oil Making Machine Work?

The sunflower oil making machine uses a continuous physical pressing process, includes the following three stages:

Feeding and Advancement

Processed sunflower seeds enter the pressing chamber from the hopper, and the rotating screw shaft pushes them into the chamber interior.

Pressing and Heating

As the screw shaft's root diameter increases and pitch decreases, the space inside the pressing chamber shrinks progressively, dramatically increasing pressure on sunflower seeds.

At the same time, huge friction resistance develops between materials, screw shaft, pressing chamber, and seed particles. This friction generates significant heat, raising the pressing chamber temperature.

Oil Extraction and Cake Discharge

High temperature and pressure completely rupture oil cells, forcing oil to flow out through gaps between the press bars. The pressed cake meal continuously exits through the cake outlet at the pressing chamber's end.

Small Sunflower Oil Press Models and Parameters

| Model |

Capacity(Kg/h) |

Power(kw) |

Screw Diameter(mm) |

Screw Speed(r/min) |

Dimensions(mm) |

Weight(kg) |

| 6YL-80 |

65-130Kg/h |

5.5KW |

φ 81mm |

47r/min |

1500×1200×1750mm |

880Kg |

| 6YL-100 |

140-280Kg/h |

7.5KW |

φ 101mm |

38r/min |

1700×1300×1850mm |

1250Kg |

| 6YL-120 |

250-400Kg/h |

11KW |

φ 120mm |

37r/min |

2000×1300×1500mm |

1500Kg |

| 6YL-160 |

300-550Kg/h |

15KW |

φ 160mm |

32r/min |

2100×1300×1600mm |

1800Kg |

Huatai Group Sunflower Oil Making Machine Features

- High Efficiency and Energy Saving: Processing 50 kg of raw materials with a 3 kW motor takes only 5 minutes, achieving efficiency several times and saving over 90% electricity.

- Simple Operation: Uses centralized electrical control with relatively low technical requirements for operators, requiring only 1-2 people.

- Multi-purpose Machine: By simply adjusting process parameters, the same machine can press not only sunflower seeds but also typically process rapeseed, peanut, soybean, sesame, walnut, tea seeds, and various other oil crops.

- Compact Structure: High integration and small footprint save factory space.

- Long Service Life: Use high-quality cast steel parts, able to long-term, high-intensity operation.

- Safe and Reliable: Includes overload protection devices that automatically stop operation when encountering hard objects or excessive pressure, protecting the core motor and transmission system from damage.

Sunflower Oil Extraction Machine Cost Analysis

Sunflower oil making machine prices depend on multiple factors including factory scale, daily processing capacity, equipment configuration, and brand. The table below shows typical configurations and investment estimates for three main scales:

| Plant Scale |

Production Capacity |

Equipment Configuration |

Equipment Investment Cost |

Total Investment Cost |

| Small-scale |

1-10 ton/day |

Roasting seed cooker, screw oil press (e.g., 6YL-80 model), oil filter |

$25,000—$80,000 |

$50,000—$150,000 |

| Medium-scale |

10-50 ton/day |

Pre-treatment equipment (cleaning, crushing, steam roasting), screw oil press(e.g., 6YL-120 model), small-scale refining machine (degumming, deacidification, decolorization, deodorization), filling machine |

$80,000-$200,000 |

$150,000—$360,000 |

| Large-scale |

50-100 ton/day |

Large-scale pretreatment production lines, pre-press + solvent extraction equipment, fully automated refining production line, automated filling lines |

$200,000-$500,000 |

$360,000-$1000,000 |

Note: These prices typically exclude freight, installation and commissioning fees, and possible import duties.

Conclusion

Overall, selecting a sunflower oil making machine requires considering multiple factors such as factory scale, extraction process, automation level, and brand. Choosing a reliable equipment manufacturer is very important when investing in the sunflower oil industry.

Henan Huatai Intelligent Equipment Group has over 37 years of experience in developing and manufacturing sunflower oil extraction equipment, including sunflower oil refining equipment. We export our equipment to Russia, Uzbekistan, Kazakhstan, Bangladesh, Nigeria, Bolivia, Ethiopia, and many other countries and regions. We also provide complete turnkey projects. If you plan to invest in the sunflower oil industry, contact us anytime or visit our factory!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ