Introduction

Canola oil is an edible oil produced from canola. Have two primary processing methods: pressing or solvent extraction. Depending on the processing degree, canola oil is categorized into crude canola oil (unrefined oil) and refined canola oil. The former is not suitable for direct human consumption, while the latter is edible.

Based on erucic acid content in canola, it is categorized into regular canola oil (3%-60% erucic acid) and low-erucic acid canola oil (erucic acid ≤3%). Recently, manufacturers have developed high-oleic acid canola oil with oleic acid content of 70% or higher, offering higher nutritional value and oxidative stability.

Research shows, China's annual canola oil consumption accounts for nearly 30% of global consumption and about 20% of domestic edible oil consumption. Canada is currently the primary exporter of canola oil, shipping over 3 million tons annually—60% of worldwide canola oil exports.

What is the Canola Oil Production Process?

The canola oil production process includes pretreatment, pressing, solvent extraction, refining, and packaging. Here's the complete process:

![9 steps of canola oil manufacturing process 9 steps of canola oil manufacturing process]()

Step 1: Canola Pretreatment

Pretreatment is the first critical stage of canola oil production, directly affecting oil yield and final product quality. Pretreatment includes:

- Cleaning: Remove impurities from canola, like sand, stones, metal fragments, stems, and leaves through screening, air separation, and magnetic separation. After cleaning, impurity content should be less than 0.1%.

- Conditioning: Adjusting canola moisture and temperature to improve plasticity. They soften canola in a roaster at 30-45°C for 30 minutes, maintaining 8-9% moisture content.

- Flaking: Flaking machines compress spherical canola into flakes (about 0.2-0.3mm thick), increasing surface area and improving cooking and oil extraction efficiency.

- Cooking: Heat breaks down oil cell structures and reduces viscosity, preparing seeds for pressing. Maintain temperatures at 110-120°C with 1-2% moisture content.

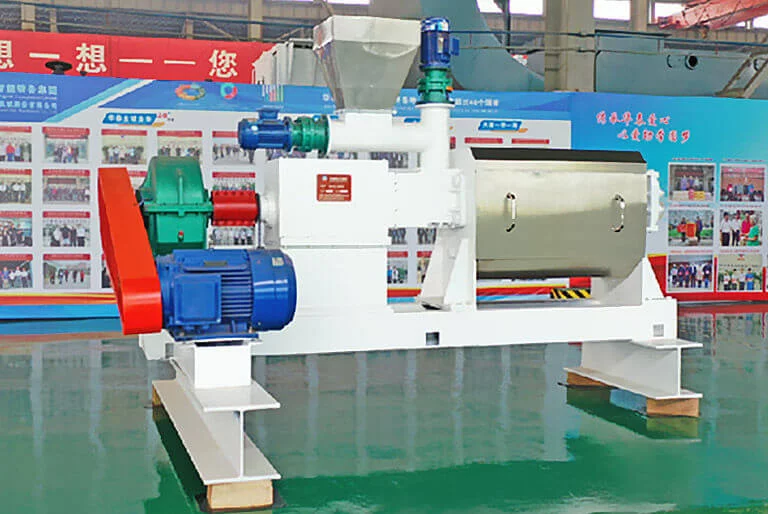

Step 2: Canola Oil Pressing

Canola oil pressing involves mechanically pressing oil through physical pressure, categorized into high-temperature hot pressing and low-temperature cold pressing.

High-temperature hot pressing: Cooked canola enters screw presses, where high temperature and pressure squeeze out the oil. This method achieves higher oil yield and richer flavor but loses some nutrients.

Low-temperature pressing: Processing below 60°C, avoiding high-temperature cooking and preserving more nutrients, but oil yield is lower. During pressing, the oil press machine controls cake thickness below 1.5mm to produce crude oil.

![Huatai Group double screw oil press Huatai Group double screw oil press]()

Step 3: Canola Oil Solvent Extraction

Use solvent extraction to extract residual oil from pressed canola cake meal (residual oil 15%-20%). This method uses solid-liquid extraction principles, using organic solvents (like hexane) to soak or spray the cake meal, extracting remaining oil. Evaporation and stripping then recover the solvent, and get crude oil.

Solvent extraction has higher oil yield than pressing, reducing residual oil to below 1%. However, it requires strict solvent residue control.

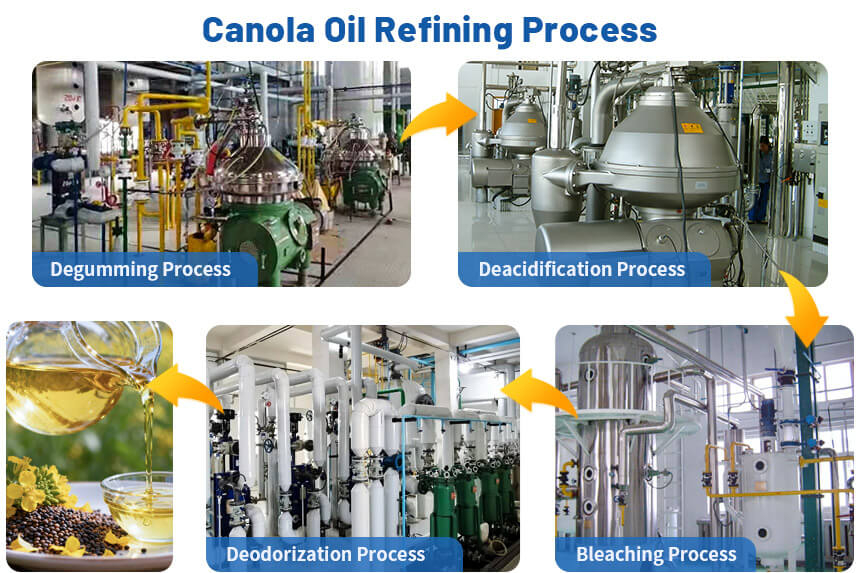

Step 4: Canola Oil Refining

Crude canola oil from pressing or extraction contains impurities (phospholipids, free fatty acids, pigments), and requires removal before human consumption. Henan Huatai Group's fully continuous refining process includes the following steps:

- Degumming: Adding water or acid removes phospholipids and gums, preventing oil cloudiness. Control operating temperature at 65-70°C.

- Deacidification: Alkali refining or distillation removes free fatty acids. Huatai Group's physical refining uses advanced continuous deacidification and deodorization process, suitable for high-acid oils, featuring strong deacidification and high refining efficiency.

- Decolorization: Under vacuum, activated clay adsorbs pigments while preventing oil oxidation. Huatai Group combines premixing with steam agitation, improving decolorization efficiency and reducing clay consumption.

- Deodorization: High temperature and vacuum with steam stripping remove off-flavors and volatile compounds, producing clear, stable oil. Huatai's continuous deodorization tower effectively prevents acid value rebound and reduces peroxide values.

Step 5: Finished Canola Oil Packaging

After passing inspection, refined canola oil packaging to ensure quality and extend shelf life. The packaging process involves three steps:

- Filtering and Cooling: Finished canola oil enters filter tank, cooling to 80-90°C, then passes through three-stage fine filtration.

- Packaging: Dark glass bottles or light-proof containers prevent oxidation during filling.

- Storage: Store finished oil in a cool, dark place. Unopened bottles last about 18 months; consumers should use opened oil within 3 months.

Canola Oil Processing Plant Cost Analysis

The cost of building a canola oil processing plant varies depending on its scale, such as raw materials, processing equipment, and transportation. The following table outlines cost estimates for different scales:

| Plant Scale |

Raw Material Cost Ratio |

Processing Cost Ratio |

Transportation Cost Ratio |

Total Investment |

Annual Sales Revenue |

| Small-scale(30 tons/day) |

50% |

35% |

15% |

$12,000,000 |

$2,700,000 |

| Medium-scale(100 tons/day) |

55% |

30% |

$35,000,000 |

$9,700,000 |

| Large-scale(300 tons/day) |

60% |

25% |

$90,000,000 |

$29,000,000 |

Global Canola Oil Production Market Analysis

Canola oil is one of the world's main edible oils, holds an important position in the global edible oil market. The following table summarizes the global market situation:

| Market Indicators |

Data and Ratios |

Notes |

| Global Vegetable Oil Production |

About 200 million tons/year |

Palm oil accounts for 35%, soybean oil 28%, canola oil 14%, sunflower oil 10% |

| Global Position of Canola Oil |

Third-largest vegetable oil |

Second only to palm oil and soybean oil |

| Main Exporting Countries |

Canada (60% of global exports), Russia, EU, UAE |

Canada exports over 3 million tons annually |

| Main Importing Countries |

United States, China, Norway, EU |

These four account for over 80% of total imports |

| China's Import Sources |

Canada (50%) |

Remaining from other countries |

| China's Consumption Share |

Nearly 30% globally |

About 20% of China's total edible oil consumption |

| High Oleic Canola Oil Market Size |

Global sales of $2.71 billion in 2024 |

Projected to reach $6.893 billion by 2031, CAGR of 15.00% |

| High Oleic Canola Oil Price |

$1,680–$2,100/ton |

/ |

Market Trends:

Supply Concentration: Canada dominates the export market, accounting for 60% of global canola oil exports.

Demand Growth: The high-oleic acid canola oil market grows rapidly, with sales expected to reach $6.893 billion by 2031 at a 15.0% annual compound growth rate, driven by health consumption trends (oleic acid helps reduce bad cholesterol).

Price Trends: In 2024, high-oleic acid canola oil averages price about $1,680-2,100/ton.

![How to set up canola oil processing plant How to set up canola oil processing plant]()

Features of Huatai Group's Canola Oil Processing Equipment

With 37 years of experience in the edible oil manufacturing equipment industry, Henan Huatai Intelligent Equipment Group's canola oil processing equipment offers the following distinct advantages:

- High Oil Yield: Increases oil yield by 1%-2% compared to traditional equipment, improving economic benefits.

- Cost-Effective: Production costs reduced by over 30%. Low equipment investment and compact footprint lower, reducing initial investment and operating costs.

- Energy-Saving & Eco-Friendly: Physical pressing and refining technology without chemical additives or waste emissions. Reducing energy consumption by over 20% compared to traditional equipment.

- Automated Control: Automatic control systems achieve production automation and precise control. Reduces labor costs and improves production stability.

- Flexible Scale: Provide complete technical equipment for processing 10-1000 tons of canola daily, meeting various investor requirements.

- Strong Raw Material Adaptability: Suitable not only for canola but also for soybeans, peanuts, sunflower seeds, rice bran, cottonseed, and other oilseeds. (Related Post: Canola oil and mustard oil difference >>)

- Turnkey Solution: Comprehensive support from design (process, civil engineering, electrical), manufacturing, installation, commissioning, technical training, to after-sales service.

Conclusion

Establishing a canola oil processing plant offers an investment opportunity with promising market prospects. Scientific process design, reasonable cost control, and choosing experienced equipment suppliers like Henan Huatai Group effectively reduce investment risks and improve market competitiveness.

As high-end product markets like high-oleic acid canola oil grow rapidly, seizing the opportunity to build a canola oil processing plant promises substantial investment returns. Whether you want to optimize your current canola oil production line or design new facilities, our experts stand ready to collaborate at every stage. Feel free to contact us anytime!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ