Introduction

Cold pressed canola oil has gained popularity in the premium edible oil market due to its unique nutritional value and pure processing method. Compared to traditional hot pressing techniques, cold pressing extracts oil directly from canola seeds using purely physical mechanical pressure at below 60℃.

This process maximizes the retention of natural nutrients in the raw material, including active components like vitamin E, phytosterols, and polyphenols.

Additionally, the cold pressing process produces canola oil with a clear color and mild flavor, which better meets modern consumers' preferences for healthy, natural foods.

In this guide, I will introduce you to the step-by-step process of making cold pressed canola oil.

Step 1: Canola Seed Reception and Storage

Before canola seeds enter cleaning and pressing stages, reception and storage form the foundation for ensuring the quality and safety of the final cold pressed oil.

Select canola seeds have plump, uniform grains with a fresh yellow-brown or black-brown color and a clean aroma, free from musty, rancid, or other off-odors.

Store canola seeds in a cool, dry, well-ventilated warehouse with constant temperature and humidity control, maintaining temperature below 15℃ and relative humidity below 65%.

![Seeds cleaning vibrating screen Seeds cleaning vibrating screen]()

Step 2: Canola Seed Cleaning

During harvest, drying, and transportation, canola seeds can pick up impurities such as mud, stones, metal shavings, and weed seeds. These contaminants affect taste and safety of final oil product and speed up wear on oil pressing equipment.

- Vibrating screen removes most large and light impurities.

- Density destoner separates stones and metal particles similar in size to the canola seeds.

- Magnetic separator adsorbs iron filings and similar materials.

The cleaning process must meet the industry standard of less than 0.5% impurity content.

Step 3: Canola Seed Dehulling

Canola seed hulls account for about 12-18% of the seed weight and contain rich cellulose, pigments, and tannins. Dehulling the seeds before pressing improves oil's color and flavor, reduces bitterness, and increases the concentration of active substances in the oil.

Dehulling typically involves crushing and air separation, requiring additional equipment. However, for premium functional canola oil products, it improves quality.

Step 4: Canola Seed Flaking

Cell walls make it difficult for oil to release fully during low-temperature pressing, resulting in lower oil yields. Flaking canola seeds with mechanical force destroys their cell wall structure, facilitating oil extraction during pressing.

The flaking process uses a specialized flaking machine. A pair of smooth rollers squeezes the canola seeds, transforming them from granules into thin flakes with a controlled thickness of 0.25-0.35 mm.

Flaking improves cold pressing oil yield by 5-10%, significantly improving economic benefits. The flaked canola seeds must meet the following requirements:

| Control Items |

Parameter Range |

Impact Factors |

| Flake thickness |

0.25-0.35mm |

Roller gap, feed rate |

| Flake powder content |

<5% |

Canola seed moisture content, roller surface condition |

| Cell destruction rate |

>85% |

Flake thickness, raw material variety |

Step 5: Conditioning (Adjust Moisture)

The moisture content of canola seeds before entering the oil press directly affects oil yield and quality. A conditioning tower maintains moisture in the optimal pressing range of 5%-8%.

Proper moisture adjustment optimizes oil fluidity and reduces cake residual oil by 0.5-1%, avoiding issues like press chamber blockage or cloudy oil output caused by unsuitable moisture levels.

Step 6: Canola Oil Pressing

The cold pressed canola oil process uses physical pressing between 45-60℃. Excessively high temperatures cause protein denaturation, vitamin E loss, and unsaturated fatty acid oxidation, which not only reduces oil's nutritional value but may also produce harmful substances. Conversely, low temperatures increase oil viscosity and reduce fluidity, hindering extraction.

Cold press oil machine uses a screw extrusion principle and segmented temperature control. By adjusting press chamber pressure, main shaft speed, and integrated water cooling system, ensure friction heat generated during pressing dissipates quickly, maintaining a low-temperature environment.

However, the cold pressing process has a relatively lower oil yield (about 5-10% lower than hot pressing).

![Cold pressed canola oil press machine for sale Cold pressed canola oil press machine for sale]()

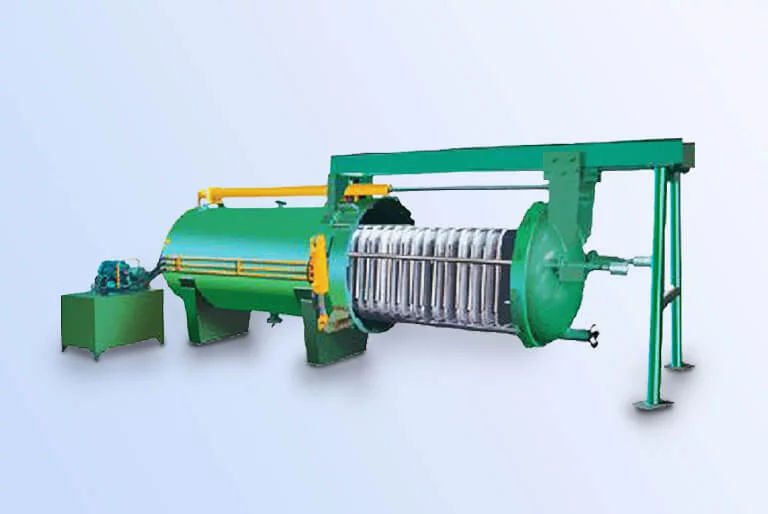

Step 7: Filtering

The crude canola oil flowing from oil press contains fine cake powder, phospholipids, proteins, mucilage, and other impurities. These substances affect oil's transparency, storage stability, and cooking performance, so filtering is necessary.

Filtering under constant temperature conditions, controlling oil temperature between 30-40℃. Temperatures are too high accelerate oil oxidation, while temperatures are too low increase oil viscosity, affecting filtering efficiency.

Traditional filtering methods mainly rely on plate-and-frame filter presses, which remove impurities through physical barrier action of filter cloths and filter papers. This method has low investment costs and suits small oil mills, but has lower filtering efficiency and requires more labor.

For large-scale cold pressed canola oil processing plants, use a combined system of settling tanks, centrifuges, and plate-and-frame filter presses. This system first removes large particle impurities through natural sedimentation, then uses centrifugal force to separate suspended matter with similar specific gravity, and finally removes micron-sized particles via precision filtration to achieve crystal-clear oil.

![Edible oil horizontal leaf filter Edible oil horizontal leaf filter]()

Step 8: Filling

Filling methods include bulk, ordinary bottling, and premium packaging. For large-scale canola oil production line, use automated filling lines that automate from empty bottle cleaning, quantitative filling, capping, labeling, to coding.

The choice of filling materials is also crucial. Dark glass bottles effectively block ultraviolet rays and prevent lipid photo-oxidation. Food-grade stainless steel barrels suit large-capacity packaging, while light-blocking PET bottles balance cost and light protection.

During filling, use advanced nitrogen-filled preservation technology. Research shows, the peroxide value of canola oil using nitrogen-filling technology rises more than 3 times slower than ordinary packaging.

Step 9: Storage

After bottling, finished oil storage in cool, dry, light-protected warehouses, prevent high temperatures speed up oil quality deterioration. The storage temperature is 15-20℃, with relative humidity below 70%.

During transportation, avoid violent vibration and exposure to sunlight and rain.

Conclusion

These are the complete steps for making cold pressed canola oil, and each step is crucial to the final oil quality.

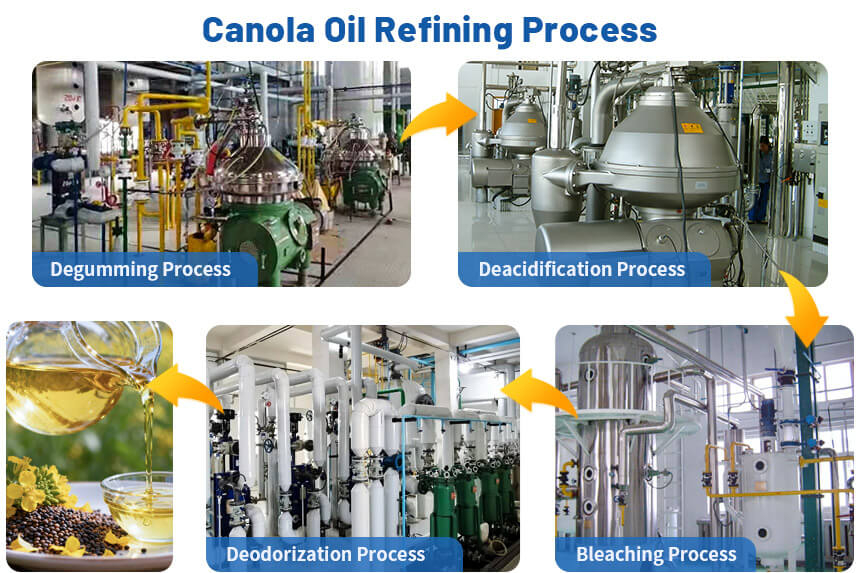

Henan Huatai Group provides and customizes complete canola oil production lines and canola oil refinery solutions, including different canola oil extraction methods such as cold pressing, hot pressing, and solvent extraction. (Related Post: Canola oil solvent extraction process >>) Feel free to consult us at any time!

Frequently Asked Questions

What is cold pressed canola oil?

Cold pressed canola oil is an edible oil extract directly from canola seeds through purely physical mechanical pressure at temperatures of 45-60℃. It has a lighter color, mild flavor, and a subtle nutty aroma.

Is cold pressed canola oil better?

Research shows, the cold pressing process can retain over 80% of the nutrients in canola seeds. It contains no trans fatty acids and has no chemical solvent residue. At the same time, it has a more robust aroma.

Is cold pressed canola oil healthy?

Cold pressed canola oil is an edible oil with high health value. It helps regulate blood lipids, lower cholesterol, maintain cardiovascular health, and has moisturizing, laxative, heat-clearing, and detoxifying effects.

Is cold pressed canola oil bad for you?

Cold pressed canola oil meets standards is safe and harmless for most people. Choose low erucic acid canola oil, store properly, and consume within the expiration date.

Is cold pressed canola oil inflammatory?

Good cold pressed canola oil does not cause inflammation; rather, it has anti-inflammatory properties. The α-linolenic acid (Omega-3 series fatty acids) rich in it can convert into anti-inflammatory substances in the body.

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ