Introduction

Coconut oil fractionation process is physical separation process. This process use coconut oil different triglycerides melting point difference, though control temperature separate coconut oil into higher melting point solid part (coconut stearin) and lower melting point liquid part (coconut oil essence or MCT enriched oil).

The coconut oil fractionation process principle is same as palm kernel oil fractionation. The following are main steps and detailed description, I will step by step explain to you.

Step 1: Crude Coconut Oil Pretreatment (Refining)

Because crude coconut oil contain free fatty acids, phospholipids, and moisture, these impurities interfere crystallization process. Therefore, the first step is pretreatment, also called refinery.

First, heat oil to 60–70°C and mix it with sodium hydroxide. This neutralizes free fatty acids, form soapstock, then centrifugation separate.

Next, use activated clay or charcoal to bleach coconut oil, remove pigments and residual soap.

Finally, at 200–250°C under vacuum, through steam distillation remove volatile compounds. And reduce moisture content to <0.1%, prevent moisture cause crystal agglomeration or emulsification.

Refining crude coconut oil ensure raw oil purity, prevent impurities interfere crystallization. (Read More about: coconut oil refining process >>)

![Refined coconut oil production process]()

Step 2: Coconut Oil Melting and Heating

This step to complete liquefy coconut oil and break down its original crystal structure.

Heat pre-treated coconut oil to 50–60°C (about 25°C above its melting point), maintain this temperature for sufficient amount time (1–2 hours), ensure all solid fats compeletely melted and form uniform liquid.

In this step, consistent heating is important. Because overheat can degrade heat-sensitive fatty acids, underheat leave solids, interference crystallization later.

![How to fractionate coconut oil]()

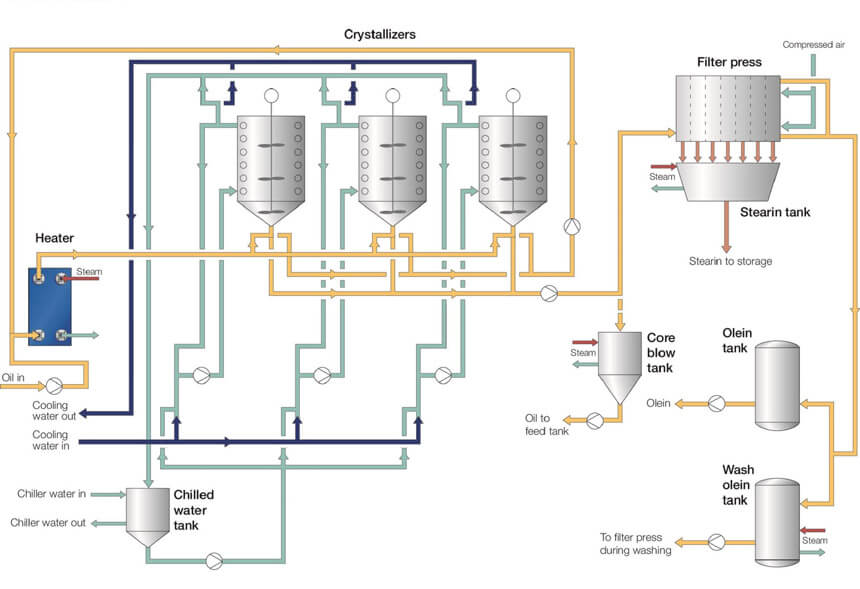

Step 3: Coconut Oil Cooling Crystallization

Cooling crystallization is heart of coconut oil fractionation process.

By slowly low temperature, high melting point triglycerides (such as lauric acid C12 and myristic acid C14 esters) first crystallize and precipitate. Low melting point components (such as octanoic acid C8 and decanoic acid C10 esters) keep liquid state.

The coconut oil cooled in three stages:

- Initial Cooling: The melt cooled to 29°C, high melting point fats start crystallize.

- Critical Cooling: Temperature drops <1°C per hour from 29°C to 24°C. This slow cooling benefit to long-chain fatty acids (LCFAs) and lauric acid form stable crystals.

- Crystallization Stage: At 24°C, medium-chain triglycerides (MCTs like C8 and C10) keep liquid, LCFAs completely solidify.

In this step, through stirring can prevent clumping, ensure crystal uniform growth. (You may also be interested in: coconut oil vs palm oil >>)

![How to make fractionated coconut oil]()

Step 4: Coconut Oil Solid-liquid Separation

The final step is separate crystallized stearin (solid state) from liquid oil concentrate. There are three commonly used methods:

Vacuum filtration

Under vacuum at 20–25°C conditions, use drum filter or plate-and-frame filter press. Set pore size of filter cloth to 20–50 μm, prevent crystal penetration and reduce residual liquid oil.

Membrane filtration

Use high pressure (0.3–0.8 MPa) to squeeze filter cake, further separating entrained liquid oil.

Centrifugal separation

Use high-speed centrifuger separate solids and liquids based on density differences.

Final products:

Liquid fraction (fractionated coconut oil): Rich in medium-chain fatty acids (C8–C10), clear and transparent at room temperature, melting point is about 0–5°C. It can use salad oil, cold-mixed oil, and health food ingredients.

Solid fraction (coconut stearin): Main contains long-chain fatty acids (C12-C18), melting point is 25–30°C, hard texture. It can use soap, cosmetics, margarine base, cocoa butter substitute.

Henan Huatai Intelligent Equipment Group’s advanced coconut oil fractionation system, achieve liquid fraction purity is 95%. Please feel free to contact us for more information.

![Coconut oil fractionation plant]()

Four Factors Affect Coconut Oil Fractionation Effect

- Cooling rate: Too fast cooling rate will result small crystals contain liquid oil; too slow cooling rate will reduce efficiency.

- Crystallization temperature: Temperature lower, liquid oil yield higher but saturation decreases.

- Stirring intensity: Vigorous stirring will break crystal structure, gentle stirring will benefit heat transfer and crystal growth.

- Separation pressure: High-pressure filter pressing can increase liquid oil yield, but may compress filter cake.

![Coconut oil fractionation machine]()

Conclusion

In conclusion, coconut oil fractionation process through refining, heating, crystallizing, and separating, produce fractionated coconut oil. To meet needs of various fields such as food, medicine, and chemicals.

Henan Huatai Intelligent Equipment Group has more than 30 years experience in manufacturing and researching coconut oil fractionation equipment. Huatai Group also provides coconut oil refining equipment, coconut oil processing plant and complete coconut oil processing production line. Feel free to consult us!

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ