Introduction

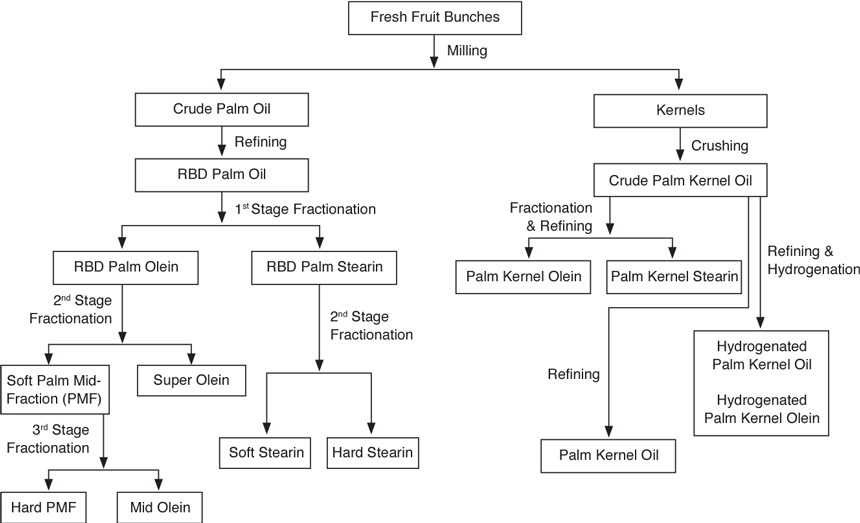

Palm kernel oil fractionation, also known as dry fractionation, is a process that physically separates crude palm kernel oil into stearin and liquid oil with different melting points and uses. This method produces no chemical additives or harmful trans fats.

In this article, I will explain in detail everything about palm kernel oil fractionation.

What Is Fractionated Palm Oil?

Fractionated palm oil comes from the controlled physical separation of palm oil or palm kernel oil. This process utilizes the differing melting points of various triglycerides present in palm oil. Through precise temperature-controlled crystallization and filtration, separate oil into fractions with different melting points, solid fat content, and application areas.

For example, high-melting-point triglycerides (such as tripalmitin, PPP) crystallize first at lower temperatures, while low-melting-point triglycerides (such as triolein, OOO) remain liquid.

![Palm oil dry fractionation process Palm oil dry fractionation process]()

What Is Palm Kernel Oil Fractionation Process?

Step 1: Crude Palm Kernel Oil Pretreatment (Refining)

The crude palm kernel oil pretreatment removes impurities and improves oil quality. The process includes degumming, deacidification, decolorization, and deodorization. The final refined palm kernel oil with an acid value (KOH) ≤0.3 mg/g, iodine value 16~19 g/100 g, melting point 25~28℃, and solid fat content (25℃) ≥18%. (Related Post: Palm oil refinery process >>)

- Mix palm kernel oil with sodium hydroxide. This neutralizes free fatty acids, forming soapstock, then separate by centrifugation.

- Use adsorbents such as activated clay to remove pigments, residual phospholipids, and oxidation products from the oil.

- Remove volatile compounds by steam distillation under vacuum conditions at 200–250°C. Reduce the moisture content to <0.1% to prevent crystal agglomeration or emulsification caused by moisture.

Step 2: Palm Kernel Oil Melting and Heating

After pretreatment, the palm kernel oil through melting and heating process. This thoroughly destroys the original crystal structure in the oil and creates consistent conditions for subsequent crystallization steps.

Heat refined palm kernel oil to 70-80℃ and maintain this temperature for 30-60 minutes. This ensures all solid fats completely melt and form a uniform liquid.

Temperature control during heating is important. Excessive temperature may increase energy consumption and degrade heat-sensitive nutrients. Insufficient temperature will leave crystals incompletely melted, affecting the crystal size and morphology in subsequent crystallization.

![Palm oil fractionation flow chart Palm oil fractionation flow chart]()

Step 3: Palm Kernel Oil Cooling and Crystallizing

Cooling crystallization is the most critical step in the dry fractionation of palm oil. By controlling the cooling rate and temperature, triglycerides with different melting points in the oil.

Research shows the optimal cooling crystallization conditions are: pre-cooling temperature 29~30℃, pre-cooling time 3 hours, crystallization temperature 24℃, and a cooling rate decreasing to 24°C at less than 1°C per hour.

During this process, high-melting-point triglycerides (such as symmetric saturated triglycerides) first form crystal nuclei and gradually grow, while low-melting-point triglycerides remain liquid. Meanwhile, slow stirring prevents clumping and ensures uniform crystal growth.

The cooling rate is the key factor affecting crystal characteristics. Speedy cooling produces crystals are too small, forming a crystal network structure that's difficult to filter. Excessively slow cooling creates crystals are too large, entrapping too much liquid oil and reducing fractionation efficiency.

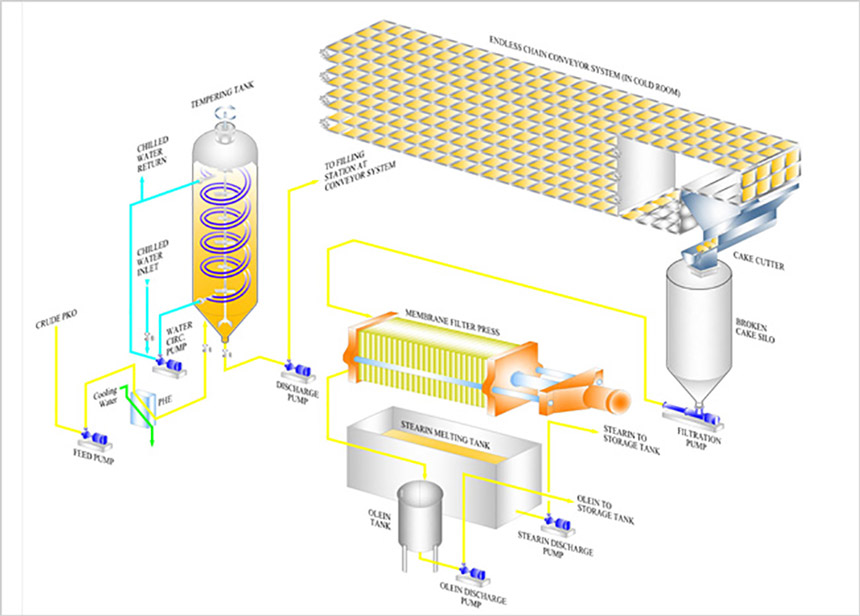

Step 4: Palm Kernel Oil Solid-Liquid Separation

After crystallization completes, separate the formed crystals (stearin) from the liquid oil (olein) using solid-liquid separation. Use high-pressure membrane filter presses for filtration, with operating parameters: filtration pressure 0~0.3 MPa, squeezing pressure 1.6~1.8 MPa. (Related Post: Palmolein oil vs palm oil >>)

Henan Huatai Group's solid-liquid separation equipment achieves complete separation of crystal cakes at low temperatures, preventing crystal melting or secondary crystallization caused by temperature fluctuations during operation. Feel free to consult us for details at any time.

Final Products:

- Palm Kernel Stearin (PKOs): Rich in saturated triglycerides, with a melting point of 30-34℃ and solid fat content of 34%-44%. As a cocoa butter substitute in applications such as chocolate, candy coatings, cream, ice cream, and a valuable raw material for high-quality soap bases.

- Palm Kernel Olein (PKOo): With a melting point of about 24-26℃, smoke point above 240℃, and iodine value (IV) between 5.6-7.5 gI/100g, it appears clear and transparent with strong oxidation stability. As a frying oil, baking oil, and a base material for various liquid oil product formulations.

![Henan Huatai palm kernel oil fractionation flow chart Henan Huatai palm kernel oil fractionation flow chart]()

What Factors Affect Palm Oil Fractionation Effects?

- Raw oil quality: For example, excessively high diacylglycerol (DAG) content (>3%) interferes with crystal formation, causing small, irregular crystals and delaying the crystallization process.

- Cooling rate: Speedy cooling produces fine crystals, leading to filtration difficulties and reduced yield. Excessively slow cooling proves inefficient. The best way is rapid cooling first to form crystal nuclei, then slow cooling to promote the growth of large, stable β' crystal form crystals.

- Stirring rate: Stirring needs to be uniform and gentle. Moderate stirring ensures uniform heat and mass transfer and prevents crystal settling. However, excessive stirring generates shear forces, breaks up already-formed crystals, producing fine crystals, hinders filtration, and reduce separation efficiency.

- Filtration machine: Must filter at a constant low temperature and adopt a progressive pressurization strategy. This avoids crystal melting or secondary crystallization and maximizes the squeezing out of liquid oil from the crystal cake, improving yield.

Fractionated vs Hydrogenated vs Crude Palm Oil

The table below is a detailed comparison of fractionated palm oil, hydrogenated palm oil, and crude palm oil in terms of processing methods, physical properties, and chemical characteristics:

| Indicators |

Fractionated palm oil |

Hydrogenated palm oil |

Crude palm oil |

| Production Process |

Physical fractionation process (dry fractionation), no chemical changes |

Chemical hydrogenation process, saturation of unsaturated fatty acids |

Mechanical pressing or solvent extraction |

| Smoke Point |

≥240°C |

220-230℃ |

200-215℃ |

| Melting Point |

30-34°C |

32-36°C |

25-28°C |

| Iodine Value |

5.6-7.5 gI/100g (stearin) |

<10 gI/100g |

16-19 gI/100g |

| Solid Fat Content (30°C) |

34%-44% |

>45% |

<18% |

| Trans Fat Content |

None |

May contain (0.5%-2%) |

None |

| Fatty Acid Composition |

Natural |

Increased saturated fatty acids, reduced unsaturated fatty acids |

Natural |

| Antioxidant Components |

Retains natural vitamin E (tocotrienols) |

High-temperature hydrogenation degrade some antioxidants |

Contains natural antioxidants like vitamin E |

| Main Uses |

Cocoa butter substitute, confectionery, baked goods |

Shortening, margarine, frying oil |

After refining, it can be used as edible oil. |

Is Fractionated Palm Kernel Oil Bad for You?

Fractionated palm kernel oil is safe and harmless to humans. Here are three reasons why:

- No harmful residues: Fractionation is a physical separation process (by temperature-controlled crystallization and filtration), doesn't involve any chemical reagents or reactions. Therefore, it absolutely doesn't produce trans fatty acids and avoids the risk of chemical residues.

- Preserves natural nutrition: The process maximally retains the natural nutritional components in palm kernel oil, such as potent antioxidant vitamin E (tocotrienols), which are beneficial to human health.

- Saturated fats: Although palm kernel oil is rich in saturated fats (such as lauric acid), moderate consumption is safe under the premise of a balanced diet.

Is Fractionated Palm Oil the Same as Hydrogenated?

No, they're different. Fractionated palm oil and hydrogenated palm oil differ in processing methods, chemical composition, trans fatty acid content, health implications, and applications.

Conclusion

Henan Huatai Intelligent Equipment Group has helped many manufacturers set up palm oil fractionation plants and optimize the palm oil fractionation process with advanced equipment and rich experience.

Whether you're looking to optimize existing palm oil milling equipment or invest in a new palm oil production plant, our technical team is ready to design a customized solution for your specific needs. Contact us today for a free consultation!

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ