Introduction

In this article, I will introduce you to the complete palm oil refining process, three different types of palm oil refining machines, and set up palm oil refinery plant cost.

What Is Refined Palm Oil?

Refined palm oil is a high-quality edible oil obtained by physically and chemically processing crude palm oil to remove impurities, free fatty acids, pigments, and odors.

The refining process transforms the originally orange-red crude palm oil with distinct smell into a finished product with clear color, mild flavor, and high stability. This process expands its application range in the food industry and cooking.

Research shows, refined palm oil maintains a nearly 1:1 ratio of saturated fatty acids (mainly palmitic acid) to unsaturated fatty acids (oleic and linoleic acids). It's also rich in vitamin E (tocotrienols), which has 40-60 times the antioxidant capacity of ordinary tocopherols.

![Palm oil refining process flow chart Palm oil refining process flow chart]()

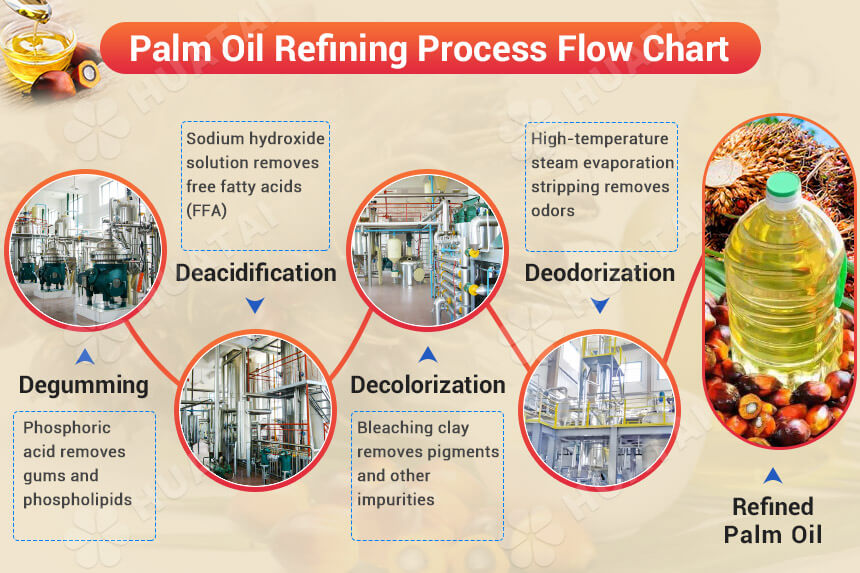

What Is the Crude Palm Oil Refining Process?

The crude palm oil refining process includes degumming, deacidification, decolorization, deodorization, and fractionation (optional). These steps remove impurities, gums, free fatty acids, pigments, and odors from crude oil while maximizing the retention of natural nutrients.

The entire refining process requires precise control of temperature, pressure, and time to ensure the quality and yield of the final product. Here are the detailed steps:

Step 1: Palm Oil Degumming

The degumming process of palm oil removes phospholipids, gums, proteins, and other impurities from crude oil. Use two main methods:

- Water degumming: Add hot water based on the phospholipid content in the raw material, causing hydratable phospholipids to swell. Then, using a disc centrifuge to separate them. This method is suitable for oils with high phospholipid content. Finally, recover the phospholipids as animal feed or further process them into lecithin for the food industry.

- Acid degumming: Add up to 0.4% phosphoric acid or citric acid to the oil, react for a period, then add water. Finally, they use a centrifuge to remove these substances. This separates phospholipids, proteins, and other impurities. This method is suitable for processing palm oil, palm kernel oil, coconut oil, olive oil, and animal fats.

Main machines: Degumming tank, disc centrifuge, hot water supply system, phosphoric acid metering unit.

Step 2: Palm Oil Deacidification

Palm oil deacidification neutralizes free fatty acids (FFA) in crude palm oil. Achieve this through a chemical reaction between alkali metal solution (sodium hydroxide) and free fatty acids, produces soap stock and water.

The deacidification process at 60°C-85°C. A centrifuge separates the soap stock. After neutralization, wash oil with water and dry it under vacuum to remove residual soap stock and impurities.

Main machines: Deacidification tank, alkali preparation system, disc centrifuge, washing tank, vacuum dryer.

Step 3: Palm Oil Decolorization

The bleaching process of palm oil uses adsorbents to remove pigments (such as carotenoids) and organic compounds from palm oil, improving the oil's purity and stability.

First, heat oil to 90-120°C, then add bleaching earth. Then, separate the bleaching agent from the oil and solvent extract to recover the residual oil contained in the bleaching clay.

Main machines: Decolorization tower, bleaching earth addition unit, vacuum system, filter (e.g., plate-and-frame filter or membrane filter).

Step 4: Palm Oil Deodorization

The deodorization process of palm oil removes odors, residual free fatty acids, and peroxides from the oil through high-temperature (200-260°C) evaporation, improving the oil's flavor and shelf life.

Achieve this process by heating the oil in a vacuum tank and injecting steam. After evaporation, rapidly cool palm oil, pump it to storage tanks, and store it under inert gas.

Main machines: Deodorization tower, vacuum system, steam ejector, heat exchange system, cooling device.

Step 5: Palm Oil Fractionation (Optional)

The fractionation of palm oil, also known as dry fractionation, is a physical separation technique. It separates palm oil into stearin and olein through controlled temperature crystallization and filtration, based on the melting point differences of different triglyceride components in palm oil.

Palm oil fractionation adds no chemical reagents and maximally preserves the natural characteristics of palm oil.

Main machines: Melting tank, crystallization tank, filter press, vacuum filter, control system.

3 Types of Different Palm Oil Refinery Plants

![Batch type palm oil refinery plant Batch type palm oil refinery plant]()

Batch Type Palm Oil Refinery Plant (1~20 Tons/Day)

A batch oil refinery plant has all refining steps sequentially in the same vessel. Each batch of oil completes the entire refining process before discharge, then processing the next batch.

Equipment components: Combined refining tank (integrating degumming, deacidification, decolorization, and deodorization functions), centrifuge, plate-and-frame filter, hot water system, and control system.

Advantages: Batch oil refinery requires low investment costs, compact structure, and small floor space (3,900×830×1,550mm). It offers quick installation and suits small-batch, multi-variety production modes. It can process various seed oils and different qualities, with simple and low-cost maintenance.

Disadvantages: Higher energy consumption, lower production efficiency, possible quality variations between product batches, higher labor requirements, and lower refining yield.

Applications: Very suitable for small-scale production, startups, or small farms. It also suits small-batch production of specific varieties of palm oil or palm kernel oil.

![Semi-continuous palm oil refinery plant Semi-continuous palm oil refinery plant]()

Semi-Continuous Palm Oil Refinery Plant (20~50 Tons/Day)

Semi-continuous oil refinery combines the features of batch and continuous systems. Some processes run continuously, while others still use batch methods.

Equipment components: Degumming tank, deacidification tank, continuous decolorization tower, semi-continuous deodorization tower, disc centrifuge group, filter group, and automated control system. Pumps and pipelines connect the equipment to achieve partial continuous operation.

Advantages: Semi-continuous oil refinery offers higher production efficiency compared to batch systems, lower unit energy consumption, more stable product quality, and moderate labor requirements. It provides the benefits of continuous production while keeping some flexibility of batch processing.

Disadvantages: Investment cost is higher than batch type, requires more installation space, demands higher operating technical, and may still have efficiency losses during transitions between different process stages.

Applications: Suitable for medium-sized companies with established stable sales channels, regional edible oil processing plants, and enterprises planning to expand capacity.

![Fully continuous palm oil refinery plant Fully continuous palm oil refinery plant]()

Fully Continuous Palm Oil Refinery Plant (50~600 Tons/Day)

Fully continuous oil refinery suits large-scale production palm oil refineries. All processes run continuously without interruption, such as the 100T/D palm oil fully continuous refining project designed and manufactured by Huatai Intelligent Equipment Group. (Watch Video: Congo 100tpd Palm Oil Refining and Fractionation Plant Video >>)

Equipment components: Continuous degumming system, continuous deacidification system, continuous decolorization tower, continuous deodorization system, automated centrifuge group, diaphragm filtration system, full-line PLC control system, and energy recovery device.

Advantages: Fully continuous machinery has high automation, very high production efficiency, low unit product cost, stable and uniform product quality, lowest energy consumption and labor requirements, and excellent environmental performance.

Disadvantages: Huge initial investment, requires large land area and infrastructure support, operation and maintenance needs advanced professional skills, and low production flexibility, suitable for single-variety large-scale production.

Applications: Suitable for large oil processing enterprises, such as large plantations in Nigeria, Malaysia and Indonesia. Also suitable for national strategic projects and international cooperation projects, such as Huatai Group's 100T/D palm oil refining and fractionation project exported to Congo.

Is Refined Palm Oil Good for Health?

Yes, refined palm oil is good for health. Because its fatty acid composition is very balanced, with saturated and unsaturated fatty acids each accounting for 50%. At the same time, its vitamin E content (tocopherols and tocotrienols) reaches 600~1000mg/kg, offering cholesterol-lowering and neuroprotective effects.

![Palm oil refinery plant cost Palm oil refinery plant cost]()

Palm Oil Refinery Investment Cost Analysis

A complete set of batch palm oil refining machine costs between $80,000 and $350,000. The cost of set up a palm oil refinery varies significantly due to factors such as mill scale, automation level, and equipment supplier. The table below shows the investment cost analysis for batch, semi-continuous, and fully continuous palm oil refining plants:

| Investment Components |

Batch refining plant (1-20TPD) |

Semi-continuous refining plant (20-50TPD) |

Fully continuous refining plant (50-600TPD) |

| Equipment Cost |

$80,000–350,000 |

$350,000–1.2 million |

$1.2–15 million |

| Installation and Commissioning |

$15,000–70,000 |

$70,000–240,000 |

$240,000–1 million |

| Land and Plant |

$30,000–150,000 |

$150,000–450,000 |

$450,000–3.6 million |

| Utilities (Water/Electricity/Gas) |

$10,000–60,000 |

$60,000–180,000 |

$180,000–2.4 million |

| Initial Capital |

$30,000–150,000 |

$150,000–450,000 |

$450,000–5 million |

Huatai Group Palm Oil Refining Machinery Features

- Flexible Design: Huatai Group oil refining machinery can process different types and qualities of crude oil, suitable for production enterprises of different scales.

- Fully Continuous Intelligent Process: Fully automated continuous control ensures stable and efficient production processes. It achieves continuous operation from crude oil to finished oil, improving production efficiency and product yield.

- Intelligent Control System: The machinery features an advanced full-line PLC control system with user-friendly operation through touch panels, real-time monitoring of production parameters, and automatic adjustment of process conditions.

- Resource Efficiency: Uses resource-saving refining processes to maximize raw material utilization and reduce energy consumption. For example, it recovers high-value components such as vitamin E from deodorization residues, thereby adding value.

- Remote Monitoring and Diagnosis: The palm oil refining machine manufactured by Huatai Group has online monitoring functions, enabling remote fault diagnosis and technical support via the internet, reducing downtime.

- International Technology: Huatai Group integrates international advanced experience with China's manufacturing advantages, and develops palm oil refining equipment suitable for the needs of different countries and regions.

Conclusion

Choosing the right palm oil refining machine determines the success and profitability of your business. Whether you need a batch refining system, or small palm oil making machine, or a fully automated continuous palm oil mill plant for large-scale production, selecting a reliable machinery supplier is very important.

Huatai Intelligent Equipment Group has over 37 years of experience in designing and manufacturing palm oil refining machinery for clients in more than 60 countries. Our engineers will customize a solution depends on your specific needs—production capacity, budget, and local market requirements, maximizing your return on investment.

Contact our technical team today for a free consultation and detailed quotation. We'll help you analyze your business case, recommend the optimal equipment configuration, and provide comprehensive support from installation to after-sales service!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ