Introduction

In this article, you will learn about the machinery used in palm oil processing and byproducts produced, as well as the price of palm oil processing machine, set up a small palm oil mill plant cost, global palm oil industry analysis and Huatai Group palm oil machinery features.

What Machines Do Palm Oil Processing Plant Use?

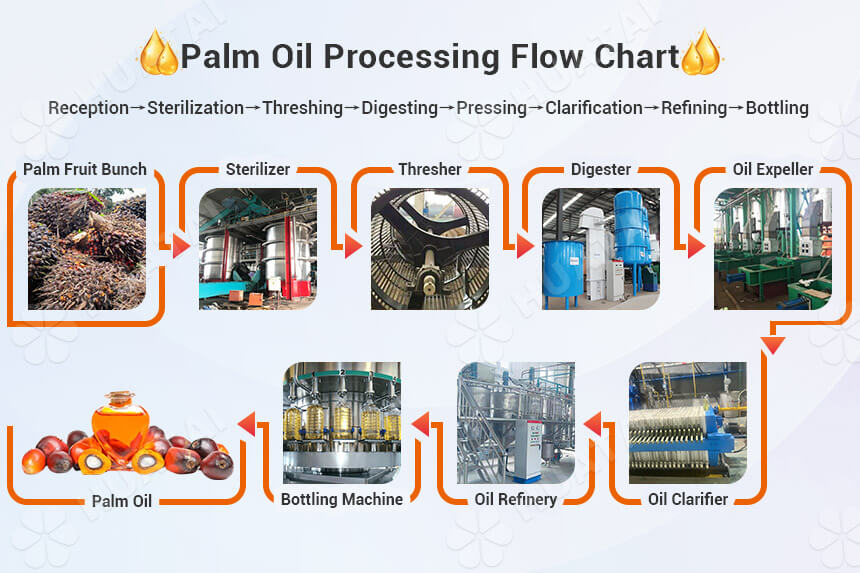

The machinery used in palm oil processing plant includes sterilizers, threshers, digesters, oil presses, oil clarifiers, refinery machines, and bottling machines.

![Palm oil processing flow chart with machine Palm oil processing flow chart with machine]()

Sterilizer

The sterilizer sterilizes palm fruit bunches and inhibits free fatty acid (FFA). It steams fresh palm fruit bunches with saturated steam (120-145℃, 2-3 bar), softening the connection between fruits and stalks for easier threshing. The sterilizer ruptures fat cell walls in the fruit pulp and inactivates lipase enzymes, releasing oils. At the same time, preventing breaking of oil into excessive FFA after processing, causes acid values to exceed standards.

Two common sterilizer types are:

- Vertical sterilizer: Batch processing with lower investment costs, but higher steam and energy consumption, and strong reliance on manual operation.

- Continuous horizontal sterilizer: Commonly used in large palm oil mills. Features uniform steam distribution, high thermal efficiency, and advanced automation.

Henan Huatai Group designs palm fruit bunch sterilizers that emphasize uniform steam flow distribution, ensuring every fruit bunch receives consistent sterilization. Contact us anytime to learn more details about our sterilization systems.

Thresher

The thresher separates softened palm fruits from sturdy empty fruit bunches after sterilization. Hammers or arms mounted on rotating drums repeatedly strike and rub the fruit bunches, causing the fruits to detach.

The drum type thresher is the most common choice. Its robust structure handles large capacities, making it suitable for large scale palm oil processing line.

Huatai Group's thresher maximizes separation efficiency by optimizing drum rotation speed, hammer angle, and screen mesh aperture.

![Setting up palm oil processing plant Setting up palm oil processing plant]()

Digester

The digester heats (90-100℃) and mechanically stirs threshed palm fruits, crushing into uniform, broken pulp. This process reduce oil viscosity and completely rupture fruit flesh cells, causing tiny oil droplets to coalesce into a continuous oil phase suitable for extraction.

The jacketed heating digester tank is the standard digester. The tank features a jacket through, steam flows for indirect heating, working together with internal multi-stage stirrers.

Oil Expeller

The oil expeller applies huge mechanical pressure to digested fruit pulp, pressing oil from solid residue. This is the core physical process for obtaining crude palm oil.

The double screw palm fruit oil press is currently mainstream and highly efficient machine. Two parallel, intermeshing screw shafts rotate in the same direction inside the press cage, conveying material forward while continuously compressing it. As the chamber volume gradually decreases, pressure rises sharply, forcing oil out.

Huatai Group palm fruit oil press machine advantages:

- Reinforced screws and cage: Using special alloy materials and surface hardening processes, has fine wear resistance. Our machine lasts far longer than industry standards, reducing maintenance costs.

- Innovative "Inverted Cone" cage design: Changed traditional uniform aperture designs to create pressure gradients that better match material characteristics. It ensures low oil residue in cake (<5%) while reducing energy consumption and wear.

- Adjustable pressing system: Operators can adjust screw rotation speed and the opening of cone resistance at cake discharge end. This flexibility adapts to different raw material batches (such as maturity and moisture content), achieving optimal oil yield.

- Synergistic operation: The process produces two products. The first is crude oil containing oil, water, and impurities, sent to clarification stage. The second is pressed cake containing fiber and kernels, sent to kernel separation station.

![Machine in the palm oil extraction plant Machine in the palm oil extraction plant]()

Oil Clarifier

Oil clarification equipment performs initial purification of hot mixed crude oil extracted from pressing (containing about 66% oil, 24% water, and 10% solid impurities), producing crude palm oil (CPO) suitable for storage, transportation or refining. Its core principle uses specific gravity differences between oil, water, and solid impurities for separation. (Related Post: Palm oil clarification process >>)

Oil clarifiers come in two main types:

Vibrating screen + continuous settling tank: This traditional process relies on natural gravity settling, requires long processing times, and large tank volumes.

Three phase centrifuge: High-speed rotation generates tremendous centrifugal force, continuously and rapidly separating crude oil into clean oil, solid sludge, and wastewater in a closed system. It offers high efficiency, large processing capacity, and very low impurity and water content in clean oil.

Clarification determines CPO quality. Excessive moisture and impurities not only increase transportation and refining costs but also accelerate hydrolysis and rancidity during storage.

![Palm oil refinery machine Palm oil refinery machine]()

Oil Refinery Machine

Palm oil refinery machines remove non-triglyceride components from CPO (such as free fatty acids, phospholipids, pigments, odor substances, and trace metals), producing refined oil suitable for food or industrial use. The specific process is as follows:

- Degumming: Add phosphoric acid or citric acid to hydrate and remove phospholipids and gums.

- Deacidification (Neutralization): Alkali refining (chemical) or distillation (physical) removes free fatty acids (FFA). Physical refining (high-temperature, high-vacuum distillation that directly removes FFA) produces no soapstock and achieves high yields.

- Decolorization (Bleaching): Under vacuum and heating, activated clay adsorbs pigments (mainly carotenoids), residual soap particles, and trace metals in oil.

- Deodorization: Under high vacuum (<3 mbar) and high temperature (240-260℃), steam distillation removes odor substances, peroxides, and residual FFA. Huatai Group's deodorization tower uses efficient plate trays and a direct steam injection system, ensuring full contact between stripping steam and oil film, achieving optimal results with minimum steam consumption. (Related Post: Palm kernel oil fractionation plant >>)

Bottling Machine

The bottling machine fills finished oil into final sales containers (such as PET bottles, tin cans, plastic barrels, flexible packaging, etc.) with precision, hygiene, and aesthetic appeal, then caps, labels, and codes.

Fully automatic rotary filling lines suit medium and large scale palm oil mills. This can automate entire process from empty bottle feeding, internal rinsing, quantitative filling, capping, to labeling and packing.

![Henan Huatai Group palm oil mill plant project Henan Huatai Group palm oil mill plant project]()

What Are the Byproducts of Palm Oil Processing?

Palm oil processing produces byproducts including empty fruit bunches, palm kernel shells, palm kernel cake, press fiber residue, and wastewater.

- Empty fruit bunches (EFB): Pressed fruit bunch fibers are traditionally compost or boiler fuel. After pretreatment, become high-quality raw materials for paper, fiberboard, and activated carbon.

- Palm kernel shell (PKS): Hard outer shells obtained after crushing palm kernels. They are high-calorific biomass fuel for steam boilers or processed into high-quality solid fuel pellets. They are also used to manufacture adsorbents or as road paving materials.

- Palm kernel cake/expeller (PKC/PKE): Residue from palm kernel oil extraction. Rich in protein and fat, it is a premium raw material in ruminant and aquatic animal feed.

- Press cake/fiber and palm nut shell: Obtained from pressing and kernel shell separation processes. Typically as fuel for boilers, providing steam and electricity for the entire processing.

- Palm Oil Mill Effluent (POME): Organic wastewater produced during processing. Anaerobic digestion produces biogas (mainly methane) on a large scale for power generation or purification into bio natural gas.

Tip: When planning a new palm oil processing factory, incorporating comprehensive byproduct utilization (such as biogas power generation and organic fertilizer production) into the overall design maximizes revenue and profit.

How Much Is a Palm Oil Processing Machine?

The cost of palm oil processing machines varies across countries due to factors like production capacity, level of automation, labor costs, raw material availability, import/export taxes, and suppliers.

Below is a country-specific price comparison for different types of machines.

| Machine Type |

Capacity(TPD) |

Nigeria(USD) |

Malaysia(USD) |

India(USD) |

Ghana(USD) |

| Small |

1-5 TPD |

$1,800 - $5,500 |

$1,500 - $4,500 |

$1,700 - $5,000 |

$1,800 - $5,800 |

| Medium-Scale |

5-20 TPD |

$6,000 - $35,000 |

$5,000 - $30,000 |

$6,500 - $32,000 |

$6,000 - $36,000 |

| Large Industrial |

>20 TPD |

$35,000 - $110,000 |

$30,000 - $100,000 |

$40,000 - $120,000 |

$35,000 - $115,000 |

| Automated |

>10 TPD |

$55,000 - $220,000 |

$50,000 - $200,000 |

$60,000 - $230,000 |

$55,000 - $225,000 |

How Much Setting up a Mini Palm Oil Mill Plant?

The cost of building a small palm oil processing plant mainly depends on construction cost and operating costs. Below we will take the setup of a 10 TPD palm oil processing plant as an example and conduct a cost analysis.

Construction Costs

| Category |

Details |

Estimated Cost(USD) |

| Land Cost |

5 hectares in a palm plantation, annual rent per hectare $246–$492, total rent for 5 Years. |

$6,145–$12,290 |

| Plant Construction |

1,000 square meters ($123–$197/㎡) |

$122,905–$196,648 |

| Equipment Procurement |

Includes screening, pressing, refining, and fractionation equipment |

$300,000–$500,000 |

| Infrastructure Support |

Water and electricity access, road leveling, etc. |

$24,581–$49,162 |

| Total Construction Costs |

A sum of all construction expenses |

$239,000–$405,000 |

Operating Costs (Monthly)

| Category |

Details |

Estimated Cost(USD) |

| Raw Material Procurement |

50 tons of palm fruit at $49 per ton |

$73,743 |

| Staff Wages |

10 workers ($368–$492 each), 2 managers ($737–$1,229 each). |

$5,162–$7,374 |

| Water, Electricity & Fuel |

Estimated monthly cost |

$1,229–$2,458 |

| Equipment Maintenance |

$1,229–$2,458 |

| Transportation & Sales |

Logistics and marketing |

$2,458–$4,916 |

| Total Operating Costs |

A sum of all monthly expenses |

$83,000–$91,000 |

Based on the above tables, you can calculate the approximate cost of building a small palm oil processing plant: total construction cost is about $239,000 - $405,000, and total monthly operating cost is about $83,000 - $91,000.

Global Palm Oil Market Analysis

According to the latest forecast data released by the U.S. Department of Agriculture (USDA) in June 2025, the global palm oil industry shows a highly concentrated and continuously growing trend. The table below shows 2025 global palm oil production rankings and market share by main producing countries.

| Country |

Annual Production (10,000 MT) |

Global Share |

| Indonesia |

4,750 |

58.8% |

| Malaysia |

1,950 |

24.2% |

| Thailand |

345 |

4.3% |

| Colombia |

190 |

2.4% |

| Nigeria |

92 |

1.1% |

| Other countries |

746.6 |

9.2% |

| Total |

8,073.6 |

100% |

Deep Analysis:

Monopoly: Indonesia and Malaysia collectively account for over 83% of global production, controlling pricing power and trade flows for palm oil worldwide.

Demand: India (8.7 million tons) and China (5 million tons) are the world's largest importers, with their demand is the main driver of the market.

Henan Huatai Group Palm Oil Machinery Features

- High extraction efficiency: Henan Huatai Group's independently developed "palm fruit oil press" uses specially selected materials and process reinforced twin screws. The China Cereals and Oils Association's authoritative expert review has confirmed that it reaches China's leading level.

- Intelligent control: Advanced PLC fully automatic control systems achieve complete automation from feeding to pressing, with monitoring and adjustment. This reduces labor costs and operational difficulty while supporting remote operation and fault diagnosis, ensuring consistent oil quality.

- Turnkey projects: Henan Huatai Group provides complete palm oil refining and fractionation project capabilities for facilities processing 100 tons per day and above. Taking the 100T/D project in the Congo as an example, Huatai Group helped our clients achieve industrial upgrading through highly mechanized and automated design, along with precise control of water, electricity, and steam consumption. (Watch Video: Congo 100tpd palm oil refining and fractionation plant project video >>)

- Global services: Henan Huatai Group has exported palm oil machinery to over 68 countries and regions worldwide, accumulating rich experience across vast palm oil producing areas from Southeast Asia to Africa.

Conclusion

Choosing the right palm oil processing machine is very important. It will affect your production efficiency, product quality, and profitability.

Huatai Intelligent Equipment Group offers turnkey solutions for palm oil mills ranging from 1-2,000 tons per day, including product design, manufacturing, installation, training and after-sales service. Contact us now for the best prices on palm oil machinery!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ