Introduction

The palm oil clarification process removes solid impurities and moisture from crude oil after pressing palm fruits to obtain pure oil.

In this guide, you will learn about the clarification steps in palm oil production plant, influencing factors, and main machinery used.

What Is Clarification in Palm Oil Processing?

Clarification in palm oil processing removes all impurities and moisture from crude palm oil. The crude oil obtained after palm fruit pressing or extracting contains oil, water, solid particles, and soluble impurities. Clarification separates these components through physical methods.

In wet palm oil processing, clarification directly determines both crude oil yield and quality. Incomplete clarification resulting in residual moisture and impurities accelerates oil rancidity, affects after refinery results, and increases machinery maintenance costs.

Henan Huatai Group palm oil processing mill optimizes the process to achieve oil yield above 98%. Feel free to contact us anytime for more details.

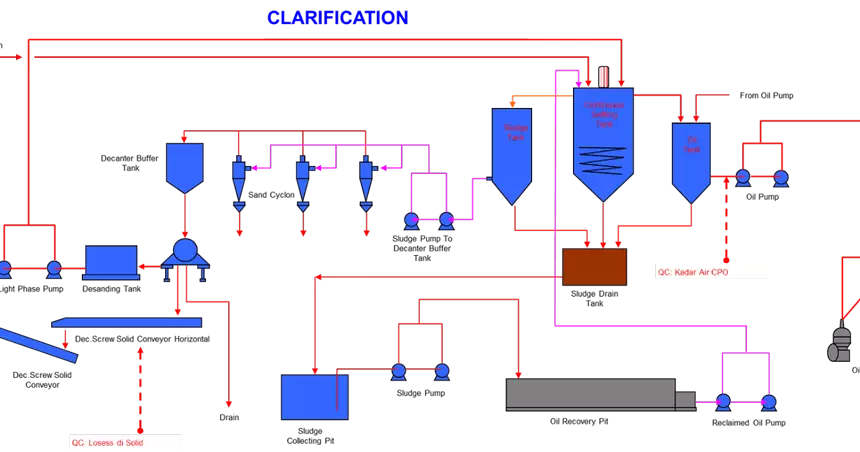

![Crude palm oil clarification process flow chart Crude palm oil clarification process flow chart]()

What Are Palm Oil Clarification Process Steps?

Step 1: Heating and Screening

The crude oil from the palm fruit oil screw press machine temperature is 50-60°C. need to heat it to 85-90°C. Then, the palm oil passes a vibrating screen or static screen (mesh size 1-2 mm), removing larger fibers and solid particles.

Heating reduces the viscosity of palm oil, making it easier to separate oil, water, and residue.

Research shows, heating the temperature to about 90°C, palm oil achieves the shortest separated time. Low temperatures (<80°C) cause excessive viscosity and reduce separation efficiency. High temperatures (>100°C) accelerate oil hydrolysis, produce more free fatty acids, affect oil quality, and increase energy consumption.

Step 2: Centrifugal Separation

Centrifugal separation is the core clarification process in palm oil mill. This process in clarification tanks or centrifuges. It utilizes the different densities of oil (0.91 g/cm³), water (1 g/cm³), and solid impurities to achieve stratification through settling or centrifugal force.

In a traditional clarification tank, palm oil needs 4-7 hours of static settling. Pure oil floats to the top while solids settle to the bottom.

Huatai Intelligent Equipment Group palm oil mill uses a three-phase horizontal screw centrifuge for separation at 3000-5000 rpm and flow rates of 10-50 m³/hour, with high efficiency and excellent results.

Step 3: Filtration Process

The upper layer of crude oil after centrifugal separation may still contain tiny suspended solid particles. Use pressure filters, such as a plate-and-frame filter or a vertical pressure leaf filter to filtering them.

For example, the Malaysian Palm Oil Board (MPOB) proposed a new clarification process that uses a "cyclone separator-filter press" combination system, which effectively removes suspended solids.

At the same time, research shows, using superhydrophobic polypropylene membranes at 40°C and 2 bar transmembrane pressure can simultaneously achieve purification and dehydration. This method achieves a non-soluble solids removal rate of 59%, a dehydration rate exceeding 99%, and improves oil clarity by 47%. This method uses lower temperatures, which helps protect oil quality.

Step 4: Drying and Cooling

The filtered crude palm oil may still contain small amounts of moisture (about 0.5%-1%). Drying reduces it to below 0.1%-0.2%, preventing oil hydrolysis and rancidity.

Drying is in vacuum dryers, lower pressure enables moisture to evaporate rapidly at lower temperatures. After drying, cool oil to below 40-45°C before entering storage tanks, preventing oxidation and deterioration at high temperatures.

Henan Huatai Group has developed an electrically heated automatic temperature-controlled clarification machine. It connects the top of the clarification tank to the drying tank by oil pipes. Heaters surround both tanks, and temperature sensors inside work with temperature controllers to achieve precise temperature control. This system suits medium and small scale palm oil mill, offering simple operation and low maintenance costs.

![Crude palm oil clarification station system Crude palm oil clarification station system]()

What Factors Affect the Clarification of Palm Oil Effect?

- Temperature: Low temperatures (<80℃) cause excessive viscosity, making solid-liquid separation difficult. High temperatures (>100℃) cause oil oxidation. The optimal range is 85-90℃.

- Fruit quality: The maturity of palm fruits, pretreatment process, and pressing conditions all affect clarification results. Immature fruits increase free fatty acid content in oil, while excessive pulp residue increases solid impurity load.

- Centrifugal parameters: Include centrifuge speed, feed rate, and differential speed.

- Water ratio: In traditional processes, the proportion of hot water added is critical for separation efficiency. Too little water fails to create the oil-water density difference, while too much water affects drying and wastewater production.

What Machines Are Used for Clarification Process in Palm Oil Mill?

The clarification process in palm oil mill uses machines including heat exchangers, vibrating screens, vertical clarification tanks, cyclone separators, centrifuges, filter presses, vacuum dryers, and coolers.

Conclusion

The palm oil clarification process is crucial for producing high-quality palm oil, including steps such as screening, separation, filtration, and drying.

Huatai Intelligent Equipment Group designs and manufactures palm oil production equipment and oil mills, offering complete turnkey solutions covering palm oil processing machine, palm oil refining machine, and palm kernel oil fractionation. Whether you're processing 10 tons or 600 tons per day, we have provided solutions to meet your needs.

Contact us today for a free consultation and discover how our clarification technology can enhance yields, reduce costs, and improve oil quality.

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ