Introduction

Small scale palm oil processing machines typically have a capacity of less than 20 tons per day, making them ideal for small and medium-sized businesses and local farmers.

This article explores small palm oil processing plants, detailing the basic equipment, setup process, costs, profit potential, and unique features of a Henan Huatai Group small palm oil mill plant.

Whether you are a farmer looking to increase the value of your palm plantation or an entrepreneur about to enter the palm oil market, this article provides practical insights to help you succeed.

What Machines Are Used for Palm Oil Processing?

A complete small scale palm oil processing plant relies on a range of specialized machines to efficiently extract and refine palm oil from fresh palm fruit bunches. Below is a detailed list of palm oil processing equipment and its role in the production process:

Palm Fruit Sterilizer

This machine uses high temperature steam (120-130°C) to sterilize the palm fruit bunches for 30-90 minutes.

The sterilization process inhibits enzyme activity, thus suppressing the production of free fatty acids (FFA), maintaining the quality of the oil and softening the palm fruits for easier threshing.

Palm Fruit Thresher

A thresher separates the palm fruit from the stalks. Threshing machines can be simple or drum type, with outputs ranging from 500 kg/hour to 15 tons/hour. An efficient threshing process improves the subsequent oil extraction.

Palm Fruit Digester

The digester crush and soften the palm fruit pulp at 90-95°C for 30-45 minutes, breaking down the cell walls to release the oil during the pressing process.

The digesters are available in both horizontal and vertical designs and can be selected according to your plant layout and capacity.

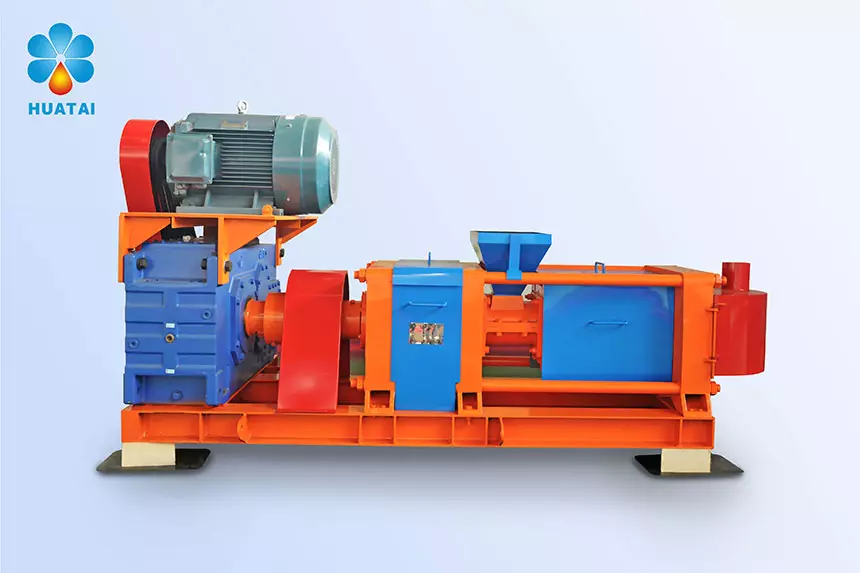

Palm Oil Screw Press Machine

The core equipment for extracting palm oil by mechanical pressing. Screw presses are available in single screw and double screw, double screw presses have higher efficiency and lower residual oil content (less than 6%).

Henan Huatai Group palm oil screw press machine the pressing capacity ranges from 300-500 kg/h to 20 tons/h. You can always consult us for more detailed information and preferential prices.

Crude Palm Oil Clarification Machine

After pressing, the crude palm oil contains impurities and water. The use of clarification equipment such as vibrating screens and settling tanks removes impurities and solids and improves the purity of the oil.

Palm Oil Filter

Plate and frame filters further purify the crude palm oil by filtering out fine impurities, resulting in a cleaner, higher quality red palm oil that can be used for storage or refining. (Related Post: crude palm oil vs refined palm oil >>)

Together, these machines form the backbone of a small palm oil mill, ensuring efficient and hygienic processing from fresh palm fruits to the gross oil.

![List of palm oil processing equipment]()

What Output of Palm Oil Processing Plant Do I Need?

Choosing the right output capacity for your small scale palm oil processing plant depends on several factors:

- Available Raw Materials: The volume of FFB you can source determines the minimum capacity. A small plantation might yield 0.5-5 tons of FFB daily, while larger estates could produce 10-20 tons.

- Market Demand: Local markets may require smaller outputs (0.5-5 tons/day), while regional or export markets might justify larger capacities (10-20 tons/day).

- Investment Capital: Smaller plants are more affordable but may have lower profit margins. Larger plants require higher upfront investment but offer economies of scale.

For example, a plantation of 2,000 hectares with an average yield of 20 tons of FFB per hectare per year, processing 12.5% monthly, requires a capacity of approximately 10 tons per hour (based on 25 days/month and 20 hours/day).

Mini palm oil processing machines (0.5-1 ton/hour) are ideal for small farms, while small scale palm oil mills (1-5 tons/hour) suit medium-sized operations.

![Small scale palm oil mill]()

How to Set Up a Small Palm Oil Mill?

Setting up a small scale palm oil mill involves several sequential steps, each requiring specific equipment and procedures:

Step #1: Fruit Reception

Receive and store fresh palm fruit bunches (FFB) from the field or market. The storage site should be close to the palm plantation to ensure fresh supply.

Sufficient space should be reserved at the storage site for truck unloading and manual handling. FFB needs to be processed within 24-48 hours to maintain the quality of palm oil.

Step #2: Threshing and Sterilizing

Fresh fruits (FFB) are fed into a palm fruit thresher, which separates the fruits from the bunches.

The fruits then enter a sterilizer where high temperature steam softens and sterilizes them, thereby inhibiting enzyme activity and preventing it from increasing free fatty acids (FFA).

Step #3: Cooking the Palm Fruits

After sterilization, the palm fruit is steamed in a digester to further soften the pulp in preparation for pressing. This step improves oil yield by breaking down the cellular structure.

Step #4: Palm Oil Extraction

Cooked palm fruits are pressed in screw palm oil presses to extract palm oil. The pressing process separates the palm oil from the fibers and nuts, of which the fibers are commonly used as biomass fuel.

Step #5: Oil Filtering and Refining

Crude Palm oil is clarified using vibrating screens and clarification tanks to remove solids and water. Subsequently, the oil is passed through filters to remove fine impurities.

Unrefined palm oil contains free fatty acids, moisture, dirt, phospholipids, fiber mixtures and pigments. Refining (degumming, decoloration, deacidification and deodorization) can further improve palm oil quality. (Read more about: palm oil refining machine >>)

Step #6: Storage

Filtered Crude Palm Oil is stored in tanks and drums, ensuring that the tanks or drums used for storage are covered with a protective coating. Appropriate storage conditions (maintained at 50°C) will extend the shelf life.

Step #7: Package and Dispatch

Finally, Package oil in bottles or drums, adding branding and labels, for sale and distribution. Efficient packaging ensures product safety and market readiness.

![Palm oil processing steps]()

Setting Up a Palm Oil Processing Plant Cost.

The setting up a small scale palm oil processing plant cost varies widely based on capacity and equipment configuration:

A mini palm oil processing plant with a capacity of about 500 kg/hour costs approximately $6,700. This setup typically includes a simple thresher, screw press, and filter.

A small to medium scale plant with 1-5 tons per hour capacity ranges from $100,000 to $260,000, depending on automation level and equipment quality.

Larger plants with capacities above 10 tons per hour can exceed $1.7 million.

Additional costs may include:

- Land and Building: Varies by region and size.

- Utilities: Power and water supply for processing.

- Labor: 2-3 workers for automated plants, more for manual operations.

![Palm oil milling machine price]()

The Profit Margin of Small Scale Palm Oil Mill.

Small scale palm oil mills can be highly profitable, especially in Nigeria and regions with strong demand.

For example, processing 10 tons of oil monthly from 40 tons of FFB at $550 per ton generates $55,000 in revenue. After accounting for raw material costs (40%, or $22,000) and operational expenses (20%, or $11,000), the profit margin is approximately $22,000 per month.

Profitability depends on:

- Raw material resources: Sourcing fresh palm fruit (FFB) directly from nearby plantations reduces raw material costs.

- Efficiency: Higher oil yields (e.g. 20-25% from fresh palm fruit) can improve profitability.

- By-product utilization: By-products such as palm kernel shell and fiber can be sold as fuel or raw material.

- Market prices: Palm oil prices fluctuate, affecting revenues.

- Operating costs: Efficient labor, energy and maintenance management are essential.

![Small palm oil mill]()

Features of Huatai Machinery Small Palm Oil Mill Plant.

Huatai Intelligent Equipment Group is a leading manufacturer with over 37 years of experience, offering advanced small scale palm oil processing plants. Key features include:

- Advanced technology: cutting-edge extraction and refining technologies are used to ensure high oil quality at high production rates.

- Fully equipped: Complete palm oil processing line machine including sterilizer, thresher, digester, press, clarifier and filter.

- Automation and durability: Automated control system reduces labor requirements to 2-3 people. Durable construction ensures long life and easy maintenance.

- Customized solutions: Tailored for production capacities from 0.5 tpd to 120 tpd for small to large projects.

- Turnkey solutions: provide complete plant setup including design, manufacturing, installation and commissioning.

- Environmentally friendly design: focusing on low energy consumption and minimal environmental impact.

- Global support: providing reliable after-sales service with a strong business network in Africa, South East Asia and Latin America.

Henan Huatai Group’s small scale palm oil mill plants are designed to meet the needs of startups and small businesses seeking reliable, cost-effective palm oil production solutions.

Conclusion

Small scale palm oil processing machines offer a promising opportunity for entrepreneurs to tap into the lucrative palm oil market. By investing in the right palm oil processing machines, following a structured setup process, and managing costs and efficiency, you can achieve significant profitability.

Henan Huatai Group’s small palm oil mill plants provide advanced, customizable, and eco-friendly solutions, making them an excellent choice for new and established producers. Our mini palm oil processing machine is especially popular for capacities ranging from 0.5 to 10 tons per day, offering affordability and ease of operation. Feel free to contact us for detailed solutions and best prices!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ