Introduction

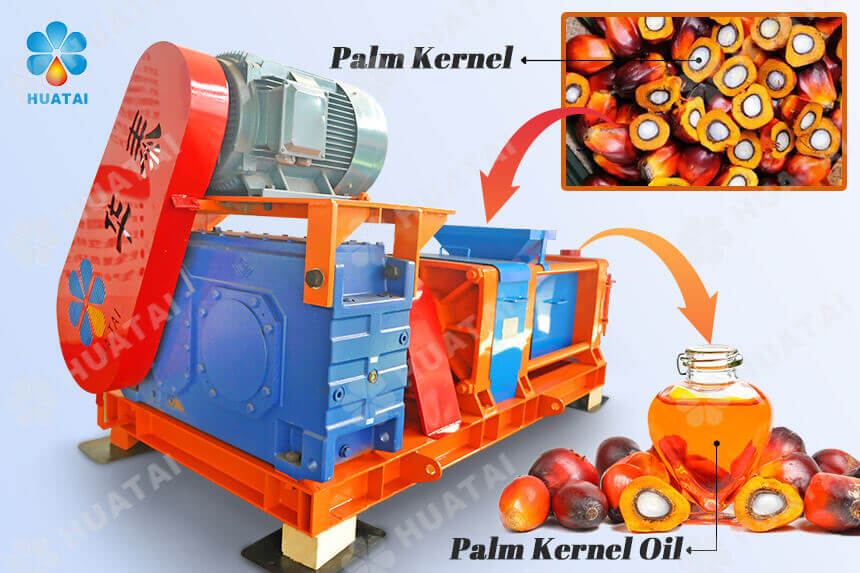

Palm kernel oil (PKO) comes from the hard kernel inside palm fruit. It maintains a 1:1 ratio of saturated to unsaturated fatty acids and is rich in vitamin E and carotenoids. It is widely used in margarine, candy, ice cream, soap, and cosmetics.

Palm kernel oil is a valuable byproduct of palm oil, the world's second-largest vegetable oil. Research shows, every 100 tons of palm oil production yields about 10-13 tons of palm kernel oil. This creates substantial profit margins for palm kernel oil processing. Investors in palm-growing countries like Indonesia, Nigeria, Malaysia, and Ghana can achieve great returns from the palm kernel oil industry.

Below, I will provide detailed information about palm kernel oil extraction machinery, its working principles and parameters, set up a palm kernel oil processing plant cost, and Henan Huatai Group's palm kernel oil machines unique advantages.

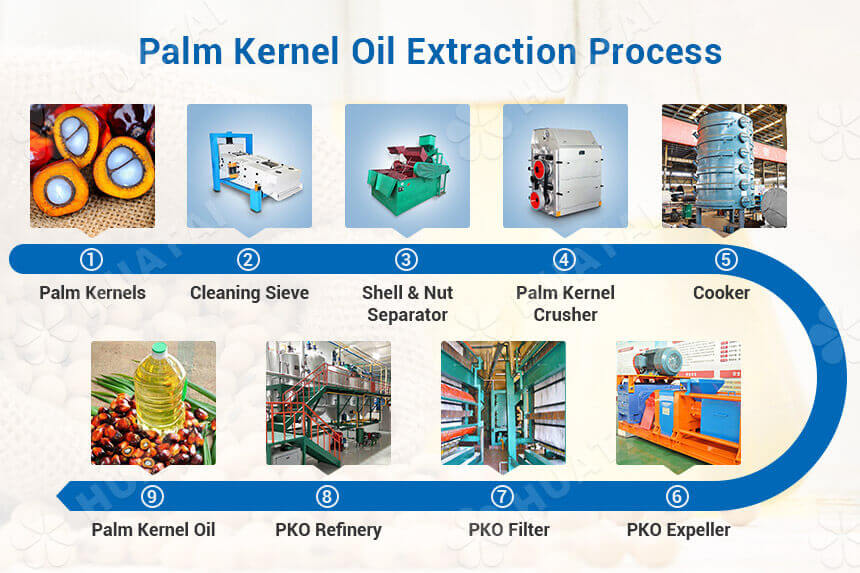

What Machines Are Used in Palm Kernel Oil Mill Plant?

![Machine used in palm kernel oil extraction process Machine used in palm kernel oil extraction process]()

Palm Kernel Cleaning Sieve

Raw palm kernels contain impurities like sand, stones, metal shavings, and fiber strands. These seriously damage machines, affect oil quality, and reduce oil yield.

Henan Huatai Group's high-efficiency cleaning sieve combines multi-layer vibrating screens with an air selection system. The vibrating screens remove heavier stones based on their specific gravity, while the air system blows away lightweight dust and husks.

Palm Kernel Shell and Nut Separator

The palm kernel shells contain very little oil, but absorb oil during processing. When shells mix with press material, reduce both oil yield and cake quality while accelerating equipment wear. Therefore, must remove the hard shell from palm kernels.

The palm kernel shelling machine operates on impact and shearing principles. High-speed rotating hammers or paired rollers with gaps strike or squeeze the palm kernels, separating the kernel from the shell. Then, sorts kernels from shells using differences in specific gravity and air velocity.

Palm Kernel Crusher

The palm kernel crusher breaks whole palm kernels into small particles (4-6 pieces). This improves the material's surface area and destroys cell wall structures, making it easier for oil to release during cooking and pressing.

Uniform crushing size is important. Particles overly coarse reduce oil yield, while too fine affect the air permeability during cooking.

Palm Kernel Cooker

The cooker uses wet heat treatment to crushed palm kernels by adjusting temperature, moisture, and time.

Cooking thoroughly destroys oil material's cell structure, denatures proteins, aggregates oil, and reduces oil viscosity. These can significantly improve oil yield and press efficiency.

Henan Huatai Group's vertical cooker uses multi-layer jacketed heating and automatic spray moistening system. This design precisely controls temperature and humidity for each layer of material, ensuring uniform and consistent conditioning.

![Palm kernel oil expeller machine for sale Palm kernel oil expeller machine for sale]()

Palm Kernel Oil Expeller Machine

The palm kernel oil expeller machine uses physical pressure to squeeze and separate oil from cooked palm kernels, producing crude palm kernel oil (CPKO).

Screw oil expeller is the main machine type for palm kernel oil extraction. A variable diameter, variable pitch screw shaft rotating inside the press cage. As material advances, the space continuously compresses, increasing pressure that squeezes out oil.

Depending on capacity and process, you can also use hydraulic oil presses for pre-pressing or cold pressing. This method offers advantages including simple technology, less supporting equipment, pure oil flavor, and good quality.

Palm Kernel Oil Filter

The palm kernel oil filter removes solid cake residue, gums, and other impurities from crude oil flowing out of the expeller, producing initially clarified crude oil.

Common types include plate and frame filters and centrifugal filters. Plate and frame filters use filter cloth and pressure for solid-liquid separation, suitable for crude oils with high residue content. Centrifugal filters separate impurities using centrifugal force from high-speed rotation. They offer higher efficiency and better suit continuous large-scale palm kernel oil production line.

Palm Kernel Oil Refinery Machine

Filtered crude oil still contains free fatty acids, phospholipids, pigments, odors, and other components. Refining removes these impurities to produce edible or industrial oils meeting different standards.

Palm kernel oil refining machinery includes the following sections:

- Degumming: Removes phospholipids and gums.

- Deacidification: Neutralizes and removes free fatty acids.

- Decolorization: Uses bleaching earth to absorb pigments.

- Deodorization: Distills and removes off-flavor substances under high vacuum and high temperature.

- Fractionation (Optional): Separates palm kernel oil into stearin and olein based on different melting points. (Read More: Palm kernel oil fractionation plant >>)

![Small scale palm kernel oil extraction machine Small scale palm kernel oil extraction machine]()

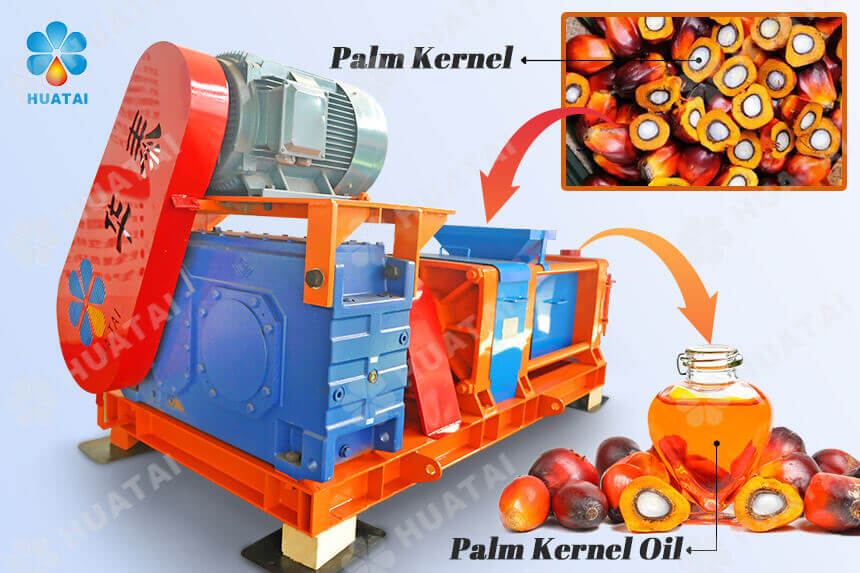

Palm Kernel Oil Pressing Machine Working Principle

Using the screw press as an example, the palm kernel oil (pko) pressing machine operates in three stages:

- Feeding and pre-pressing stage: The screw propels palm kernels into the press chamber and begins initial compaction, expelling some air.

- Main pressing stage: The variable diameter press chamber subjects palm kernels to great spatial compression force. This thoroughly destroys cell structures, and high pressure squeezes large amounts of oil from cell gaps. Controlling pressure and temperature during this stage is very important.

- Cake formation and residue discharge stage: After thorough oil press, the material forms hard cakes (palm kernel meal). The machine continuously extrudes cakes from out port at the end of chamber. You can control cake thickness and residual oil rate by adjusting out port gap.

Huatai Group Palm Kernel Oil Expeller Machine Parameters

| Parameter |

Value |

| Patent Number |

ZL 2020 2 0239333.0 |

| Processing Capacity |

2-20 ton/hour |

| Main Motor Power |

32-38 kW |

| Cake Oil Residue Rate in Cake |

5-6% |

| Shaft Speed |

10-12 r/min |

| Lifespan |

9 months |

| Size |

5550*1360*830 mm |

Huatai Group Palm Kernel Oil Machine Features

Henan Huatai Group offers advanced palm kernel oil processing machines with the following features: (Related Post: Palm oil processing machine >>)

- High Efficiency: Their palm kernel oil screw press machines achieve high oil extraction rates with low residual oil in cake.

- Durability: Made with robust materials to withstand continuous operation and harsh conditions.

- User-Friendly Operation: Simple controls and easy maintenance reduce labor requirements.

- Complete Processing Lines: Huatai provides turnkey palm kernel oil mill plants including shell cracking, crushing, cooking, pressing, clarification, filtration, and refinery equipment.

- Customization: Machines can be tailored to different capacities and customer needs, from small scale palm kernel oil extraction machines to large industrial plants.

- Competitive Palm Kernel Oil Extraction Machine Price: Huatai Machinery offers cost-effective solutions that balance quality and affordability.

![Palm kernel oil processing plant Palm kernel oil processing plant]()

How Much Does Set a Palm Kernel Oil Processing Plant?

The cost to set up a palm kernel oil (pko) processing plant depends on capacity and automation level:

Small Scale Palm Kernel Oil Extraction Machine: For capacities around 500 kg to 1 ton per hour, prices range from $5,000 to $15,000 depending on features and brand.

Medium to Large Palm Kernel Oil Mill Plants: Plants with capacities above 5 tons per hour can cost between $50,000 and $200,000, including full processing lines from shelling to refinery.

Other costs include installation, site preparation, labor, and working capital.

Investing in quality machinery like Henan Huatai Group palm kernel oil processing machines ensures durability and efficiency, optimizing your return on investment.

Conclusion

Overall, with global demand for vegetable oils continuing to rise, palm kernel oil processing has a great investment opportunity. At Henan Huatai Group, we've helped businesses in Africa and Asia establish successful oil processing operations with our palm kernel oil processing machine and comprehensive support.

Henan Huatai Intelligent Equipment Group provides complete factory design, equipment installation, staff training, and technical support to ensure your palm kernel oil plant operation runs smoothly from day one.

Contact Henan Huatai Group today for a free consultation and customized quotation. Let our experts help you design the perfect palm kernel oil processing plant for your specific needs and budget!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ