Introduction

In this article, I will take you through the machine in rice bran oil extraction process, the rice bran oil extraction plant project, and Henan Huatai Group's property rice bran oil extraction technology.

What Machines Do You Need for Rice Bran Oil Extraction Process?

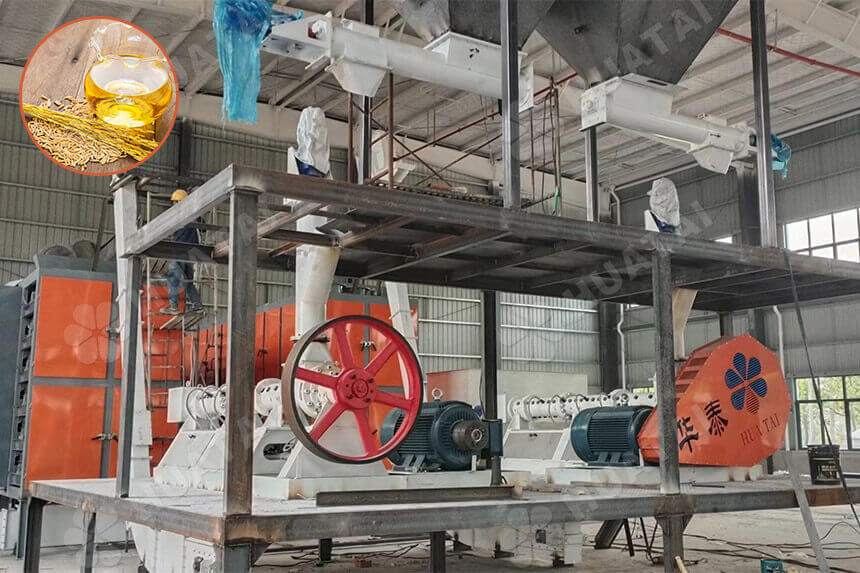

The rice bran oil extraction process uses some key machinery: cleaning sieves, tempering machines, extruders, solvent extractors, filters, refinery equipment, and bottling machines. The image below shows the complete flowchart of rice bran oil extraction machinery.

![Machines used in rice bran oil extraction process Machines used in rice bran oil extraction process]()

Rice Bran Cleaning Sieve

The cleaning sieve removes various impurities (2-5%) from rice bran, including broken rice, rice husks, straw, dust, and iron filings. These impurities not only reduce oil yield but also wear down machinery. Commonly use two types of cleaning sieves:

- Vibrating cleaning sieve: High-frequency vibration separates rice bran from impurities based on differences in particle size and specific gravity.

- Rotary cleaning sieve: The rotating drum causes rice bran to tumble forward inside the drum, and fine impurities fall through the sieve holes.

Huatai Group uses a combination design of double-layer high-efficiency vibrating screens and permanent magnet drums, cleaning efficiency of ≥98%. The screens use wear-resistant stainless steel perforated plates, which last 3 times longer than conventional steel wire mesh.

Rice Bran Tempering Machine

The tempering machine adjusts the moisture content of rice bran (from 10-13% to 14-16%) and temperature (to 70-85℃), breaking down its cellular structure and reducing oil viscosity, achieving the optimal plasticity for extrusion.

The tempering machine has a jacketed cylindrical body with an internal stirring shaft and steam injection system. Stirring blades push the rice bran forward, making it full contact with indirect steam (jacket heating) and direct steam (moisture adjustment).

Huatai Group's tempering machines use multi-point temperature and humidity sensors integrated with PLC automatic feedback control systems, ensuring constant parameters while reducing steam consumption by about 15%.

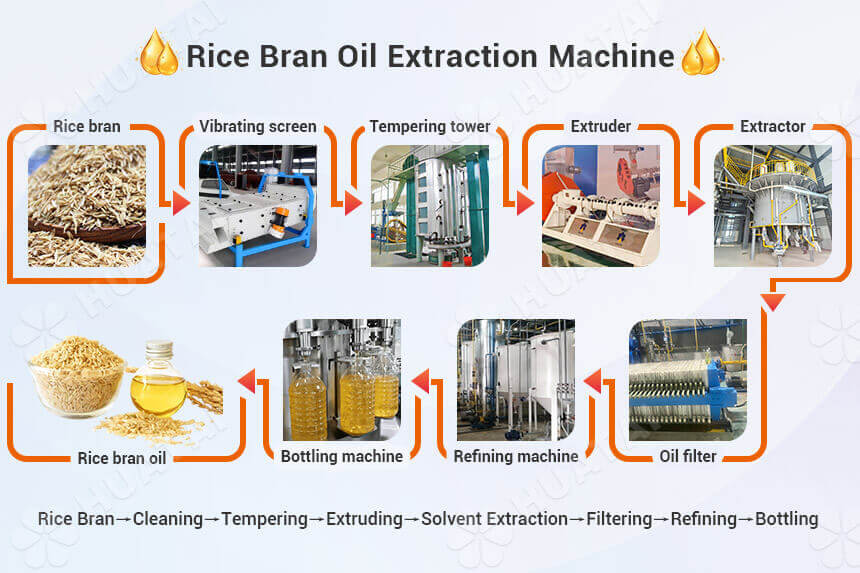

![Rice bran extrusion extruder for sale Rice bran extrusion extruder for sale]()

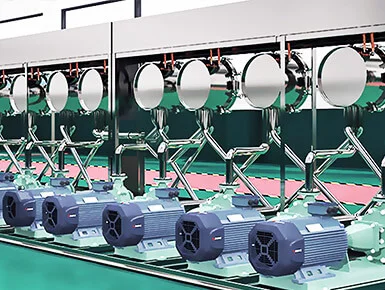

Rice Bran Extruder Machine

The rice bran extruder transforms tempered rice bran through extrusion and expansion into puffed particles (puffed bran) with loose structure and uniform porosity. Here's how it works:

- The screw pushes and compresses rice bran, subjecting it to gradually increasing pressure (up to 4MPa) and temperature (110-130℃) inside the chamber.

- The cellular structure breaks down completely, fully exposing the oils.

- When rice bran exits through the die, pressure drops suddenly, moisture evaporates instantly, and a porous structure forms.

After the extruder processes rice bran, its bulk density increases from about 380kg/m³ to 500kg/m³, improving the extractor's processing capacity by 30%. Meanwhile, the residual oil rate drops below 1%, and oil yield increases from 10% to over 18%.

Research shows, expansion reduces solvent consumption by about 10kg per ton of rice bran and steam consumption by about 20%, significantly reducing cost.

Rice Bran Oil Solvent Extractor

The bice bran oil solvent extractor uses solvents like n-hexane to extract over 95% of the oil from puffed bran through countercurrent extraction. Commonly use two types of extractors:

Rotocel extractor: The main body consists of a slowly rotating cylindrical compartmented rotor, with puffed bran into extraction cells. Fresh solvent sprays in from the meal discharge end, makes countercurrent contact with puffed bran, and the system draws out increasingly concentrated miscella (oil-solvent mixture) from the feed end.

Loop-type extractor: Chain plates convey puffed bran to an annular sealed shell, creating countercurrent flow with sprayed solvent. This design suits large-scale rice bran oil production lines.

Huatai extractors use hydraulic stepless speed drives to precisely control material layer thickness (1.2-1.5 meters) and residence time (60-70 minutes). Multi-stage layered spray systems ensure thorough saturation of puffed bran. The tail gas recovery system keeps solvent loss at the international advanced level of ≤0.5kg per ton of material.

Rice Bran Oil Filter

The rice bran oil filter removes impurities like solid cake chips from crude rice bran oil obtained after evaporation and stripping of mixed oil, providing clean crude oil for refinery. Filtration reduces impurity content in crude oil from 0.1% to below 0.01%. Commonly use two types of filters:

- Plate-and-frame filter: High filtration accuracy, but requires many labor and consumes filter cloth quickly. Suitable for small batches or crude oil with high impurity content.

- Leaf filter: High automation with stainless steel filter screens or filter cloth. Hydraulic systems control opening/closing of filter, enabling automatic sludge discharge and backwash cleaning.

Huatai Group's vertical leaf filter uses a unique vibrating sludge discharge device, ensuring more thorough meal discharge and low residual oil in filter cakes. Contact us anytime for the best price.

![Rice bran oil plant built by Henan Huatai Group Rice bran oil plant built by Henan Huatai Group]()

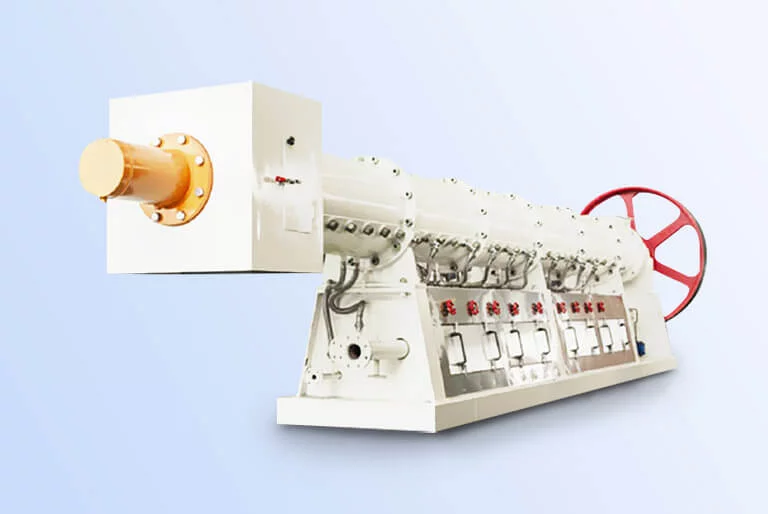

Rice Bran Oil Refining Machine

The rice bran oil refining machine removes gum, free fatty acids, pigments, odor substances, and wax from crude rice bran oil through degumming, deacidification, decolorization, deodorization, and dewaxing (winterization), producing edible oil suitable for direct human consumption. The system combines the following core equipment: (Related Post: Rice bran oil refining process >>)

- Degumming tank: Add water or acid to convert non-hydrated phospholipids in rice bran oil into hydrated phospholipids, then separate by centrifugation.

- Deacidification tower: High temperature (240-260℃) and high vacuum (absolute pressure ≤3mbar) directly distill and remove free fatty acids.

- Decolorization tank: Under vacuum and heating, activated clay adsorbs pigments, residual phospholipids, and oxidation products.

- Deodorization tower: At high temperature (240-260℃) and higher vacuum (absolute pressure ≤1.5mbar) with direct steam, removes small molecule aldehydes and ketones causing off-flavors and residual fatty acids.

- Crystallization tank: Programmed cooling (gradually reducing from 50℃ to 5℃ within 24 hours) and holding at 5℃ for over 72 hours, causes wax to form stable large crystals, filtration then removes.

Advantages of Henan Huatai Group's Rice Bran Oil Refining Machinery:

- The deacidification tower uses a combined design of packed tower and plate tower, ensuring uniform steam distribution and short residence time. This efficiently removes acids while maximally retaining oryzanol (retention rate ≥85%).

- The decolorization tank uses a closed design with automatic quantitative clay feeding, multi-stage stirring, and vertical leaf filtration, reducing clay consumption and oil loss.

- The deodorization tower uses multi-layer tray structure with thin oil layers, high mass transfer efficiency, and low steam consumption.

Rice Bran Oil Bottling Machine

This machine is fully automatic for metering, filling, capping, labeling, and coding of refined rice bran oil. You can choose filling lines for different capacities (e.g., 5L, 1L, etc.) using PET bottles or glass bottles. Common filling lines include two types:

- Line filling machine: Suits flexible production with multiple varieties and medium output.

- Rotary filling Machine: Suits single-variety, large-batch, high-speed production, with speeds reaching thousands of bottles per hour.

Tip: Rice bran oil is rich in unsaturated fatty acids and prone to oxidation. Pre-filling bottles with nitrogen to displace air reduces residual headspace oxygen to below 1%, significantly extending shelf life.

What Is Rice Bran Oil?

Rice bran is a mixture of the husk, seed coat, germ, and small fragments of rice removed during rice milling, accounting for about 7%-9% of rice.

Rice bran oil is rich in oryzanol (3-10g/kg), tocotrienols, phytosterols (≥8g/kg), and squalene (3g/kg), making it highly nutritious.

The ratio of saturated fatty acids, monounsaturated fatty acids (oleic acid), and polyunsaturated fatty acids (linoleic acid) in rice bran oil approaches 1:1:1. For this reason, the World Health Organization (WHO) recommends it as one of the three healthiest edible oils.

![100 tons per day rice bran oil extraction plant project 100 tons per day rice bran oil extraction plant project]()

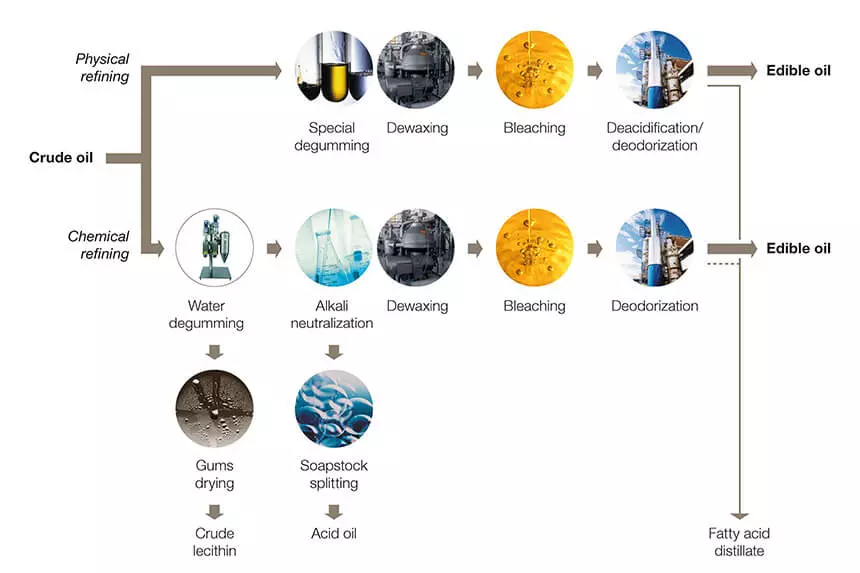

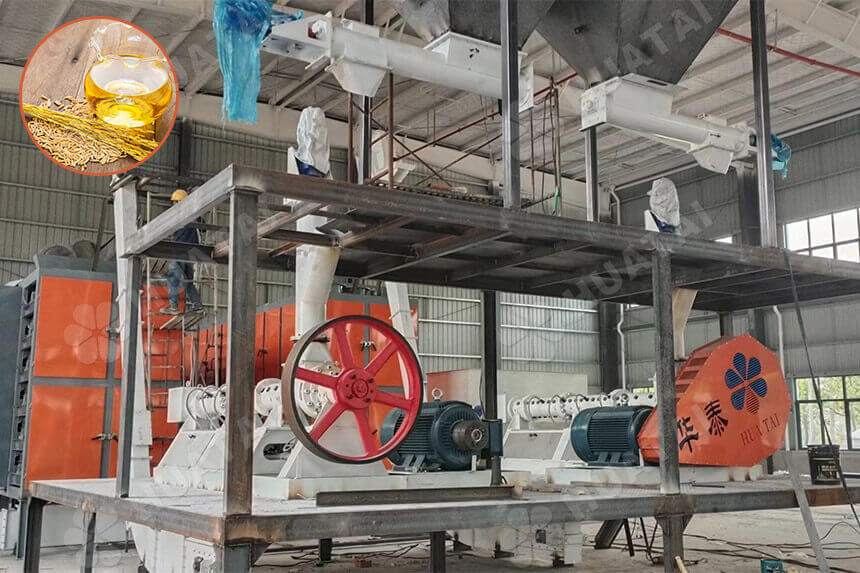

100TPD Rice Bran Oil Extraction Plant Project

In August 2024, Henan Huatai Group shipped a complete set of equipment for a 100 ton per day rice bran expansion and extraction project to Wuchang City, Heilongjiang Province. Huatai Group designed, manufactured, installed, and commissioned.

Project Background

Wuchang City and its surrounding areas have intensive rice processing industries, rich fresh rice bran resources. This project achieves local processing, perfectly solving the issue of rice bran's extreme susceptibility to rancidity (requiring processing within 24 hours). It holds in nutritional components and oil freshness from the source.

Project Core Technical Solutions

Efficient expansion: Uses Huatai's independently developed efficient energy-saving rice bran extruder, achieving a lipase inactivation rate of >95%.

Integrated solvent extraction system: With fully enclosed, low-solvent-consumption rotocel extractor and negative pressure evaporation system, achieving meal residual oil rate of ≤1.0%, solvent consumption of ≤2.5 kg/ton of material, and steam consumption of ≤280 kg/ton of material. (Related Post: Rice bran oil solvent extraction plant >>)

Integrated refinery system: Uses mild refining processes like low-temperature deodorization, with oryzanol retention rate ≥85%.

Project Value Insights

For investors, this project validates the feasibility of the "grain-producing area + professional equipment + timely processing" business model. It not only creates dual profits from rice bran oil and rice bran meal but also improves the value of local rice byproducts.

![Henan Huatai Group rice bran oil extraction patented technology Henan Huatai Group rice bran oil extraction patented technology]()

Henan Huatai Group Rice Bran Oil Extraction Patented Technology

As the Intelligent Innovation R&D Center for Oil Equipment of the China Cereals and Oils Association, Henan Huatai Intelligent Equipment Group invests 10% of annual sales revenue into research and development. Our independently developed rice bran extruder for rice bran's characteristics of low density, poor fluidity, and easy agglomeration.

Through unique screw configuration, temperature control systems, and discharge dies, achieve efficient expansion at lower temperatures.This significantly reduces oxidation and rancidity during rice bran pretreatment.

The resulting puffed bran has superior porosity, enabling more uniform and thorough solvent penetration during extraction. Thus, oil yield increases while solvent consumption and steam energy reduce.

Why Choose Henan Huatai Group?

- Patented technologies: Has 7 national patents for rice bran oil production lines, extrusion processing, and refinery equipment, ensuring cutting-edge solutions.

- Energy-saving and low residual oil: Heat energy recycling, steam consumption reduced by 30%. The residual oil rate of oil solvent extraction line is ≤1%.

- Industry leadership: As the earliest research enterprise in rice bran oil equipment in China, designed and built the country’s first fully continuous rice bran oil production line.

- Customizable solutions: Provides tailored solutions for capacities ranging from mini rice bran oil machines (3-5 TPD) to large industrial plants (up to 2000 TPD).

- Full certification guarantee: Certified by ISO9001, CE, BV, in line with international safety standards.

- One-stop service: From equipment customization to installation and commissioning, providing lifelong technical support.

Conclusion

With the professional rice bran oil machine and technology, you can transform rice bran into premium cooking oil that gets huge profits.

Henan Huatai Group has 38 years of experience in designing, manufacturing, and installing complete rice bran oil extraction plant from small 10TPD to large-scale 500TPD.

Contact Henan Huatai Group today for a free consultation and customized quotation for your rice bran oil extraction project!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ