Introduction

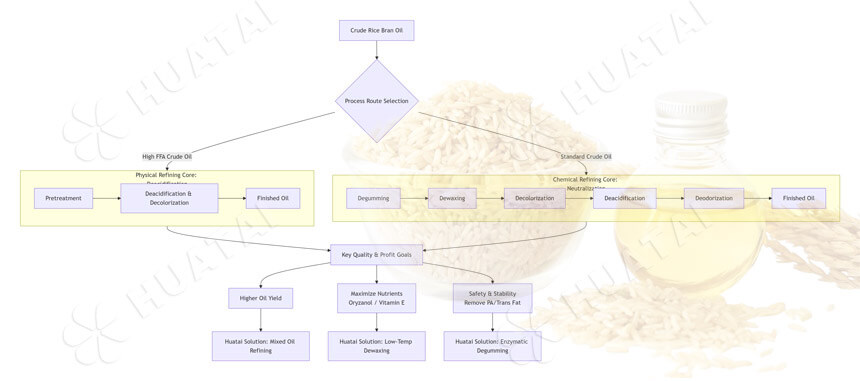

Rice bran oil stands out as one of the healthiest edible oils available today, rich in oryzanol, vitamin E, and phytosterols. However, crude rice bran oil contains impurities, waxes, and free fatty acids, and cannot eat directly. It needs to be refined.

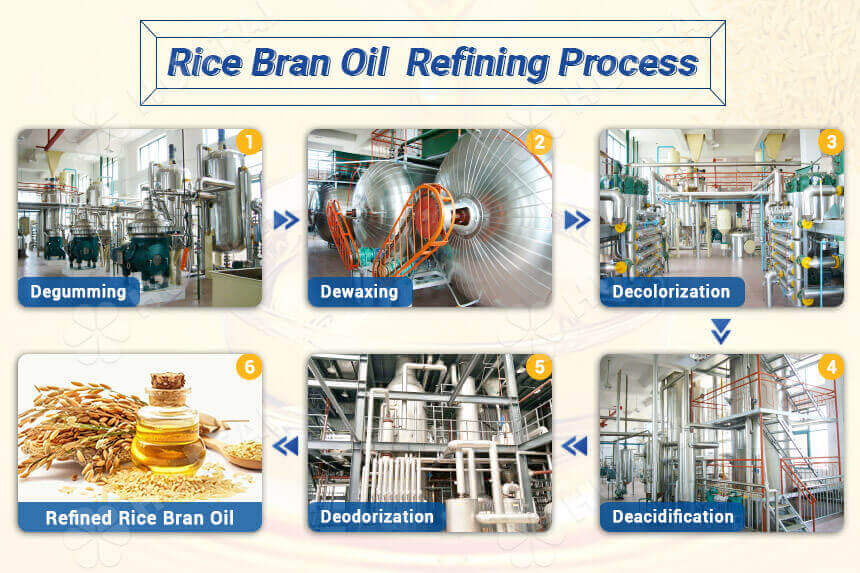

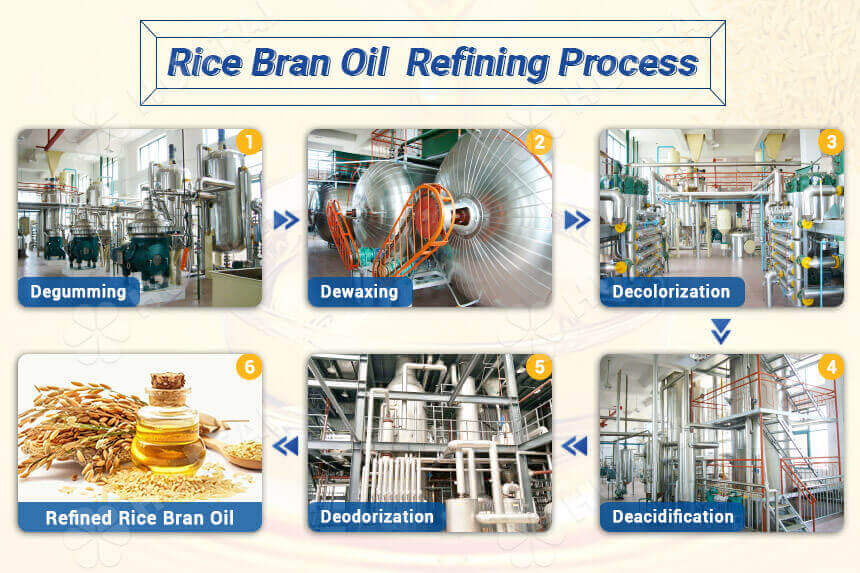

In this article, I will introduce the rice bran oil refining process includes degumming, dewaxing (winterization), decolorization (bleaching), deacidification (neutralization), and deodorization. And different methods and machines are used for each step.

![Degumming section in rice bran oil refining process plant Degumming section in rice bran oil refining process plant]()

Step 1: Rice Bran Oil Degumming

Degumming removes phospholipids from crude rice bran oil, preventing them from carbonizing and darkening after heating, which affects oil color and stability. These are three degumming methods:

- Water degumming: Add hot water to hydrate and coagulate phospholipids, then separate. The operation is simple, but it achieves low removal efficiency for non-hydratable phospholipids.

- Acid degumming: Add phosphoric acid or citric acid, convert non-hydratable phospholipids into hydratable forms, and remove. Research shows, phosphoric acid degumming effectively reduces total gum and wax content in rice bran oil.

- Enzymatic degumming: This method uses phospholipase to selectively hydrolyze phospholipids. The mild reaction conditions preserve valuable nutrients like oryzanol while minimizing wastewater discharge.

The main equipment for rice bran oil degumming includes acid/water mixing tanks, reaction tanks, and disc centrifuges.

Henan Huatai Group's edible oil degumming machine uses corrosion-resistant stainless steel materials. Our system ensures thorough and uniform contact between acid/enzyme and oil, ensuring effective degumming while minimizing oil hydrolysis. Our engineering team will customize the most economical degumming solution based on your crude oil's phospholipid composition.

![Dewaxing section in rice bran oil refining process plant Dewaxing section in rice bran oil refining process plant]()

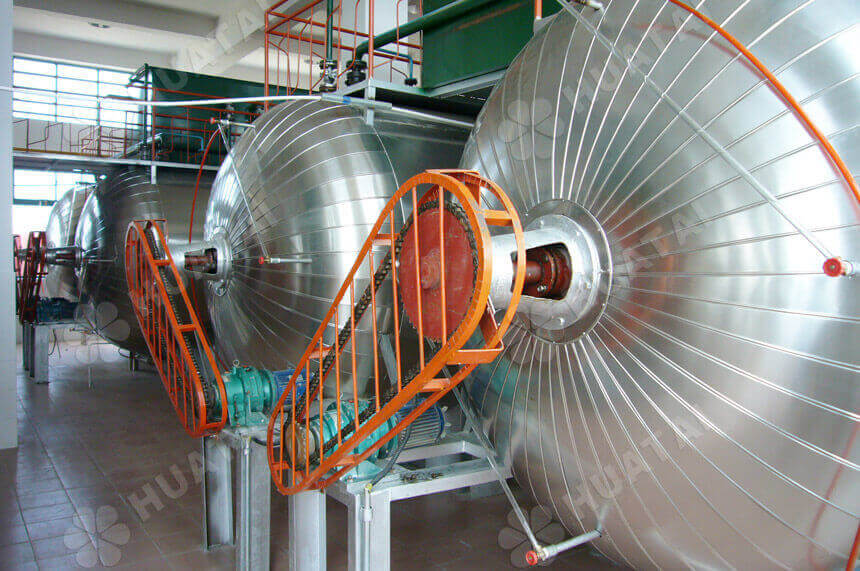

Step 2: Rice Bran Oil Dewaxing (Winterization)

Rice bran oil contains high wax content, easily crystallizes at room temperature, causing oil to become cloudy. Dewaxing removes these high-melting-point waxes, ensuring clarity at low temperatures. These are three dewaxing methods:

- Cooling crystallization-filtration method: This process gradually cools rice bran oil to 10-15°C, wax crystals to grow, then separates through filtration or centrifugation. This method is stable, effective, and widely applicable.

- Low-temperature dewaxing: Research shows, dewaxing at 10°C or even lower temperatures produces high-quality oil with light color and low total gum and wax content, regardless of whether the rice bran oil has low or high acid value.

- Mixed oil dewaxing: This method dewaxes in a mixed oil system with hexane, reducing oil viscosity and making wax crystals easier to separate. It particularly suits crude rice bran oil with high free fatty acid content.

The main equipment for rice bran oil dewaxing includes crystallization tanks, crystal-nurturing tanks, plate-and-frame filters or disc centrifuges.

Henan Huatai Group's multi-stage gradient cooling crystallization system precisely controls cooling rate, promoting the formation of large, firm wax crystals that dramatically improve filtration efficiency and yield. Our machine features efficient refrigerant systems and insulation design, energy consumption.

![Decolorization section in rice bran oil refining process plant Decolorization section in rice bran oil refining process plant]()

Step 3: Rice Bran Oil Decolorization (Bleaching)

Decolorization uses adsorbents to remove pigments (such as chlorophyll and carotenoids) from rice bran oil while further eliminating trace metals, residual phospholipids, and oxidation products. These are three decolorization methods:

Adsorption decolorization: Uses activated clay or activated carbon to adsorb pigments under vacuum at 105-120°C. Research shows, optimal decolorization conditions are at 120°C for 20 minutes.

Silica gel decolorization: Employs silica gel column percolation or direct mixing adsorption. It has good selective adsorption for certain difficult to remove pigments and can simplify the refining process (by integrating degumming and dewaxing steps).

Molecular distillation decolorization (Physical Refining): During molecular distillation, the process removes some pigments simultaneously with deacidification.

The main equipment for rice bran oil decolorization includes decolorization towers, vacuum systems, clay quantitative addition devices, and vertical leaf filters.

Henan Huatai Group produces fully automatic decolorization systems, achieve quantitative clay addition, vacuum drying, adsorption reaction, and spent clay filtration. By strictly controlling decolorization temperature and time, achieve oryzanol retention rates as high as 90.2%.

![Deacidification section in rice bran oil refining process plant Deacidification section in rice bran oil refining process plant]()

Step 4: Rice Bran Oil Deacidification (Neutralization)

Deacidification removes free fatty acids (FFA), improving oil yield, flavor, and stability. These are three deacidification methods:

- Chemical alkali refining: Add alkali solution to neutralize FFA, producing soap stock, then separate. The process is mature but causes significant losses when treating high-acid-value oil and generates wastewater.

- Biological refining (enzymatic deacidification): This method uses lipase to catalyze the reaction between FFA and glycerol, regenerating glycerides. The mild conditions preserve nutrients exceptionally well and suit crude oil with very high acid values (FFA > 30%). This energy-efficient method has excellent economic benefits.

- Combined deacidification: For very high acid value oil, it can also use a "physical + chemical" combination method. Research shows, first reducing acid value through physical refining, then using chemical refining, achieves the highest rice bran oil yield of 87.2% with 87.6% oryzanol retention.

Different deacidification methods require different machines, such as:

- Physical refining: Deacidification tower, high-temperature thermal oil system, high-vacuum system, fatty acid condensation recovery system.

- Chemical alkali refining: Alkali preparation tank, mixer, ultra-high-speed disc centrifuge, vacuum dryer.

Henan Huatai Group manufactures multi-stage steam distillation deacidification systems and advanced molecular distillation machine. Our extremely high vacuum lowers operating temperature, protecting oryzanol and tocopherols.

![Deodorization section in rice bran oil refining process plant Deodorization section in rice bran oil refining process plant]()

Step 5: Rice Bran Oil Deodorization

Deodorization is the final step in rice bran oil refinery. Through high-temperature, high-vacuum steam distillation, it removes aldehyde and ketone compounds that cause off-flavors and odors, residual FFA, and peroxides, improving smoke point and oxidation stability. Deodorization methods are divided into semi-continuous and fully continuous:

- Batch/semi-continuous deodorization: Suitable for multi-variety, small-batch production.

- Full continuous deodorization: This is the standard configuration for a large-scale rice bran oil production line, with high efficiency, stable energy consumption, and product quality.

The main equipment for rice bran oil deodorization includes deodorization towers, steam jet vacuum systems, thermal oil furnaces, fatty acid traps, and heat exchanger.

Henan Huatai Group's continuous physical refining deodorization tower features built-in exact temperature control and multi-stage vacuum systems, ensuring complete deodorization with minimal heat damage. It achieves retention rates of over 97.6% for gamma-oryzanol, 94.5% for sterols, and 91.9% for vitamin E.

Conclusion

The above are the complete steps in the rice bran oil refining process. Choosing the high-efficiency refinery technology and rice bran oil machine manufacturer directly impacts product quality, operational costs, and profit.

Henan Huatai Intelligent Equipment Group has independently developed advanced rice bran oil refinery technology, helps our customers build defference scale rice bran oil plants and achieve profitability.

Contact us today for a free consultation and customized proposal. Let's together produce premium rice bran oil while maximizing your return on investment.

![Rice bran oil refining process flow chart Rice bran oil refining process flow chart]()

Frequently Asked Questions

What is refined rice bran oil?

Refined rice bran oil is a clear, stable, and safe edible oil after crude oil through degumming, dewaxing, decolorization, deacidification, and deodorization to remove impurities, off-flavors, and harmful components.

Is refined rice bran oil healthy?

Yes, it is healthy. While refining removes impurities, it effectively preserves core nutrients like gamma-oryzanol and vitamin E.

What are the methods for refining rice bran oil?

The main methods for refining rice bran oil include chemical refining (alkali neutralization), physical refining (molecular distillation), biological refining (enzymatic method), mixed oil refining.

What is physically refined rice bran oil?

Physically refined rice bran oil uses distillation as the main method to remove free fatty acids. This process produces no soap stock wastewater, preserves nutrients well, and minimizes refining losses.

What is the difference between refined rice bran oil and crude oil?

Refined rice bran oil is clear and transparent with high smoke point, no off-flavors, and good oxidation stability, suitable for direct consumption. Crude oil is cloudy with high acid value, contains many impurities, easily turns rancid, and cannot consume directly.

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ