Introduction

The steps for rice bran oil solvent extraction plant include: rice bran pretreatment (puffing), solvent extraction, wet meal desolventization, miscella evaporation and stripping, and solvent condensation and recovery.

Step 1: Rice Bran Pretreatment

Because raw rice bran contains oil, fiber, and impurities like husk, dust, and broken rice. Without pretreatment, these impurities can reduce extraction efficiency and compromise oil quality. (Related Post: Complete rice bran oil manufacturing process >>)

Cleaning and Conditioning

Raw bran passes through a vibrating sieve and magnetic separator to remove coarse impurities, ensuring only pure bran enters the extraction system.

The cleaned bran then undergoes conditioning in a vertical stack cooker, where operators adjust moisture levels to 8–10% and elevate temperatures to 60–70°C.

This thermal treatment deactivates lipase enzymes that could otherwise degrade oil quality during storage.

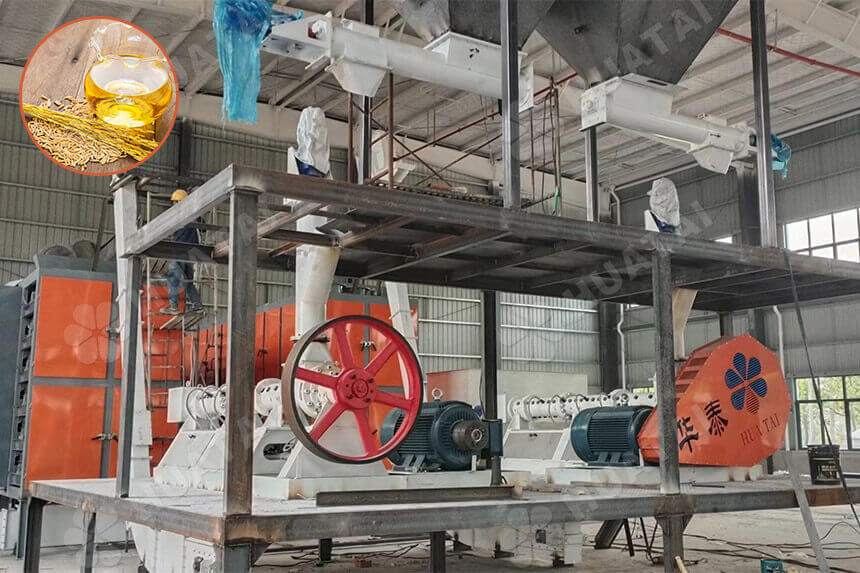

![Rice bran oil extraction machine for sale Rice bran oil extraction machine for sale]()

Puffing and Drying

The conditioned bran is fed into an extruder or expander, where high-pressure mechanical shear and steam injection transform it into porous, granular pellets. This "puffing" step increases surface area by 300–400%, improving solvent penetration.

The expanded material is then dried to 3–5% moisture in a plate dryer, cooling it to 50–55°C to prevent solvent vaporization during extraction.

Step 2: Rice Bran Solvent Extraction

The pre-treated (expansion) rice bran forms porous pellets, enter extractor. Solvent (hexane) contacts it thoroughly through countercurrent spray extraction, dissolving the oils to form miscella (mixed oil).

Strictly controls four parameters during rice bran solvent extraction:

- Solvent temperature: 50-55°C to ensure good solvent flowability and permeability while preventing excessive solvent evaporation due to high temperatures.

- Material temperature: Rice bran stays at 50-55°C, matching the solvent temperature. This reduces heat exchange losses and promotes oil dissolution.

- Solvent ratio and concentration: 1:0.8 and 1:1.1. For rice bran with an oil content of 18-20%, thorough extraction produces miscella concentrations exceeding 18-27%.

- Extraction time: 90-120 minutes, ensuring the residual oil in rice bran meal is below 1%.

![Rice bran DTDC desolvention machine Rice bran DTDC desolvention machine]()

Step 3: Wet Meal Desolventization

The wet rice bran meal exits extractor contains 25-35% solvent, must be thoroughly removed and recovered to ensure feed safety and improve meal's nutritional value.

DTDC desolventizer toaster processes the wet meal through continuous "pre-desolventization - desolventization - drying - cooling" stages.

Pre-desolventization layer section: Using secondary steam rising from lower layers to preheat and initially desolventize the upper wet meal, saving 15-20% of steam consumption.

Desolventization layer section: Material layer height at 500-750 mm. Stirring paddles rotating at 10-12 r/min suspend the material, allowing it to contact direct steam thoroughly. The system controls steam penetration density at 650-750 kg/(h·m²) with temperatures reaching 105°C. This ensures rapid solvent evaporation while promoting Maillard reactions, improving meal's flavor and color.

Through precise temperature and time control, stabilize the finished meal's urease activity between 0.15-0.25, ensuring protein quality. The system reduces residual solvent content in the meal to below 300 mg/kg while keeping protein dispersibility index (PDI) above 75%.

![Mixed oil evaporation and stripping tower Mixed oil evaporation and stripping tower]()

Step 4: Mixed Oil Evaporation and Stripping

The mixed oil obtained from the extractor undergoes evaporation, concentration and stripping to yield crude rice bran oil (CRBO) with purity exceeding 99.5%. The process is as follows:

- The first long-tube evaporator raises mixed oil concentration to 70% at 60°C.

- The second long-tube evaporator uses fresh steam heating to improve concentration above 95%.

- Finally, the oil enters the stripping tower.

Under vacuum (pressure ≤350 mbar) and direct steam distillation, stripping tower thoroughly removes any remaining solvent from the miscella. Reduce mixed oil's solvent content below 500 ppm, achieving purity above 99.5%. The crude rice bran oil obtained through evaporation and stripping can be further refinery, produce edible oil suitable for direct consumption. (Read More: Rice bran oil refinery plant >>)

![Solvent condensation and recovery system Solvent condensation and recovery system]()

Step 5: Solvent Condensation and Recovery

Solvent recovery directly impacts production costs, environmental safety, and continuous plant operation. This system condenses solvent vapor from all equipment including extractor, desolventizer, evaporators, and stripping tower.

Pipelines collect solvent vapor from all equipment and direct it into condenser groups. Typically uses multi-stage condensation processes:

- Primary condensation: Circulating water (30-32°C) condenses most of the solvent vapors.

- Secondary condensation: Low-temperature chilled water (below 7°C) condenses low-boiling-point and residual solvent vapor.

After efficient recovery, the system consumes only 1.5-2.5 kg of solvent per ton of rice bran material processed.

![Rice bran oil solvent extraction plant built by Huatai Group Rice bran oil solvent extraction plant built by Huatai Group]()

Henan Huatai Group's Solvent Extraction Equipment Features

- National Patent Technology: Henan Huatai Group offers rotocel, loop-type, and patented drag-chain extractor (Patent No.: ZL 2018 2 1882277.1), meeting different capacity requirements for rice bran oil extraction plants.

- Full Model Range Coverage: Providing desolventization system models ranging from 100 tons/day to 6,000 tons/day processing capacity, allowing you to select based on your project needs.

- Intelligent Control: Integrated PLC and SCADA-based intelligent control system, achieves fully automatic control of extractor start-stop, stepless speed regulation, and material bin level monitoring. This simplifies operation and reduces human error.

- Versatile Materials: Our equipment body is made of stainless steel, composite steel plates, or special alloys, suitable for the trace fatty acid environment potentially present in rice bran oil. This ensures long-term corrosion resistance. Our design and manufacturing follow strict domestic and international standards including GB and ASME.

- High-Efficiency Condensation Technology: Through optimized condenser structure and flow path design, combined with efficient jacketed cooling and metal wire mesh falling film filtration technologies, our condensation recovery efficiency exceeds industry average by over 30%, significantly reducing refrigeration energy consumption.

- System Integration Design: Designs stripping tower together with evaporators and condensers as an integrated system, providing reliable equipment foundation for achieving energy savings.

![100 tons per day rice bran oil processing plant project 100 tons per day rice bran oil processing plant project]()

Conclusion

Henan Huatai Intelligent Equipment Group manufactures rice bran oil solvent extraction plants from small 10 ton daily rice bran oil machine to large-scale 3,000 ton daily rice bran oil production line. Our machinery is stable and reliable, meeting international quality standards.

At the same time, Henan Huatai Group provides complete support from initial consultation and engineering design through installation, commissioning, and ongoing technical assistance.

Contact us today to discuss your specific requirements and discover how our advanced oil solvent extraction technology can reduce your costs, improve oil yield.

Frequently Asked Questions

What is the solvent extraction of rice bran?

Solvent extraction of rice bran uses a solvent, typically hexane, to dissolve and separate oil from rice bran. This efficient method extracts oil from the bran, a rice milling byproduct, and is commonly used industrially for high oil recovery.

How much oil can be extracted from rice bran?

Rice bran contains about 15-20% oil by weight. With solvent extraction, up to 95% of this oil can be recovered. The exact amount varies depending on bran quality and extraction technology.

How much oil can be extracted from 1 kg of rice bran?

From 1 kg of bran, 150–230 grams of oil is theoretically possible (15–23% oil content). Real-world extraction recovers 130–220 grams (85–95% efficiency). High-yield plants using puffing and hexane achieve up to 190–200 grams per kg.

What is the capacity of a rice bran oil solvent extraction plant?

Huatai Intelligent Equipment Group's rice bran oil solvent extraction plant production capacity is 30-1000 tons. Capacity depends on extractor type (Rotocel, loop, or drag chain) and solvent recovery efficiency.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ