Introduction

Sesame oil is edible vegetable oil extracted from sesame seeds, rich in sesamol and sesamolin. They are beneficial to health. Sesame seeds have oil content of 45%~63%. If you are looking for sesame oil extraction machine or want to setup sesame oil processing plant to start your sesame oil business, you have come to right place!

Henan Huatai Group's sesame oil extraction machines use extract edible oil from all plant seeds and nuts. From seed pretreatment to finished oil packaging, we can provide high-quality sesame oil machinery and complete sesame oil processing solutions.

Sesame Seeds Pretreatment Machine

Sesame seeds pretreatment removes impurities, ensure process only high-quality sesame seeds. This step can improve sesame oil yield and quality. The following equipment is used:

Cleaning Screen

The cleaning screen removes large impurities (such as straw, hemp rope, and stones) and small impurities (such as dust, fine sand particles, and imperfect grains) from sesame seeds.

Commonly used types include vibrating screen and flat rotating screen.

![Sesame seeds cleaning screen Sesame seeds cleaning screen]()

Remove Stone Machine

The stone remover use principles of density differences and vibrating air separation.

It can remove similar in size and density sesame seeds heavy impurities (such as stones and metal pieces).

Magnetic Separator

Magnetic separator remove mixed ferromagnetic metal impurities (such as nails, screws, and iron filings) from sesame seeds, protect subsequent equipments (especially sesame oil press) from damage.

Common types include permanent magnet drums and magnetic frames.

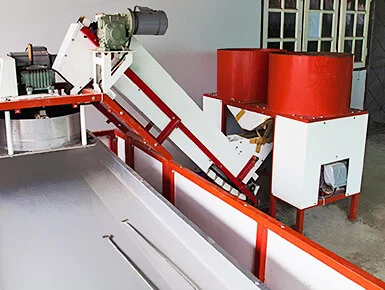

Elevator

Conveys sesame seeds vertically or at an angle to different processing stages, such as from cleaning to seeds frying, or from seeds frying to oil press machine hopper.

The most common elevator type is bucket elevator.

![Bucket elevator Bucket elevator]()

Color sorter (optional)

Color sorters operate based optical recognition and airflow projection.

For high-quality sesame oil, used to remove moldy grains, discolored grains (such as white sesame seeds in black sesame seeds, or black sesame seeds in white sesame seeds), and diseased grains, thereby improving raw material purity and oil quality.

Sesame Roasting/Conditioning Equipment

Through heating and stirring, reduce sesame seeds moisture content to about 7%, proteins denature, and broken down cell structures, producing distinctive rich aroma of sesame.

Control of temperature, time, and stirring speed is critical. Common machine types include:

- Drum-type frying machine: Continuous or semi-continuous production, high thermal efficiency.

- Flat plate dryer: Batch operation, easy to observe and control.

Sesame Oil Press Machine

Sesame oil is physically extracted. The sesame oil press machine is main of sesame oil production process. Two primary types are used: screw oil press machine and hydraulic oil press machine.

![Screw sesame oil press machine Screw sesame oil press machine]()

Screw Oil Press Machine

The screw oil press is core machine for modern sesame oil extraction process, oil yield is 30%~35%.

First, continuous feed roasted sesame into pressing chamber. Then, pressing chamber generate mechanical pressure, rotating inside spiral shaft, squeezing sesame paste to separate and extract oil from the cells. Finally, produce crude sesame oil and sesame cake (meal).

You can select different pressing chamber structures (cold pressing or hot pressing) based on process requirement.

![Hydraulic sesame oil press machine Hydraulic sesame oil press machine]()

Hydraulic Oil Press Machine: (Traditional or Small-Scale)

Sesame seeds are wrapped in filter cloth form cakes, which are placed in pressing chamber. A hydraulic system apply static high pressure slowly extract the oil.

Hydraulic oil press oil yield is 45%~47%, can result in thorough sesame oil extraction. But they have long cycles, low efficiency, and operate intermittently. They are main used for small-scale production or low-temperature pressing.

Crude Sesame Oil Processing/Refining Equipment

Crude sesame oil from oil press machine contains impurities, must remove to produce marketable sesame oil. We can use physical separate methods, preserve oil flavor and nutrition.

Crude Oil Storage Tank

The crude oil storage tank is used to collect crude sesame oil from the oil press. It serves to buffer and initially settle larger particles.

Plate Frame Filter Press

The plate frame filter press is most commonly used filtration equipment. By use chambers formed by filter cloth and filter plates, under pressure, filter solid suspended impurities (such as cake particles, fibers, and gum) out of crude sesame oil, get clear sesame oil.

Horizontal Screw Settling Centrifuge

The horizontal screw settling centrifuge is efficient solid-liquid separation equipment.

By use high-speed rotate generate centrifugal force, fast separate crude sesame oil larger solid particles and some gum. It is suit large-scale continuous production.

Clarification Tank

The clarification tank use gravity sedimentation principle. After filter, oil sits in tank for a while. Tiny impurities and some phospholipids and other hydrated impurities slow settle to bottom, leaving clearer layer of sesame oil on top.

However, this step usually takes a long time (hours to days).

![Sesame oil refining machine Sesame oil refining machine]()

Sesame Oil Refining Machine (Optional)

If you need higher quality sesame oil requirements, such as salad sesame oil or cooking sesame oil, refining is necessary.

However, traditional sesame oil is usually processed only by filtering and settling. Chemical refining (degumming, neutralization, bleaching, deodorization) is not used. Because it will severely deplete aromatic compounds and trace nutrients.

- Degumming tank: Add water or acid remove phospholipids and other colloidal impurities.

- Neutralization tank: Add alkali neutralize and remove free fatty acids.

- Decolorization tank: Add white clay/activated carbon adsorb pigments, remove trace metals, and residual soap residues.

- Deodorization tower: Distill under high temperature and high vacuum to remove off-flavor substances, residual free fatty acids, and small molecular volatile substances.

Finished Oil Processing and Filling Equipment

Fine Filtration/Safety Filter

Before filling, settled or refined sesame oil through final precision filtration (using filter cartridges or filter bags) remove any extremely small particles (such as white clay particles or crystallized wax).

Ensure sesame oil clear and transparent, meet filling requirement.

Finished Oil Storage Tanks

Finished oil storage tanks used to store qualified sesame oil awaiting filling, maintaining consistent quality.

![Sesame oil filling production line Sesame oil filling production line]()

Filling Machine

The filling machine is used to quantitatively fill finished sesame oil into bottles (glass bottles, PET bottles) or drums of various specifications.

It include units such as bottle sorting, rinsing (if required), filling, capping/sealing, labeling, and coding.

Packaging Equipment

The filled bottles are subjected to outer packaging, such as boxing, crating, sealing, and bundling.

![Sesame oil processing plant Sesame oil processing plant]()

Conclusion

Choose reliable sesame oil extraction machine is important. Henan Huatai Intelligent Equipment Group sesame oil machine provides comprehensive production solutions for all sizes, from small sesame oil processing plant to large complete sesame oil production line.

Our equipment combines traditional oil extraction principles with advanced technology, maintain sesame oil quality and nutritional value, achieve optimal yields.

Welcome to contact us for more details about our sesame oil making machine or price. We are always at your service!

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ