Introduction

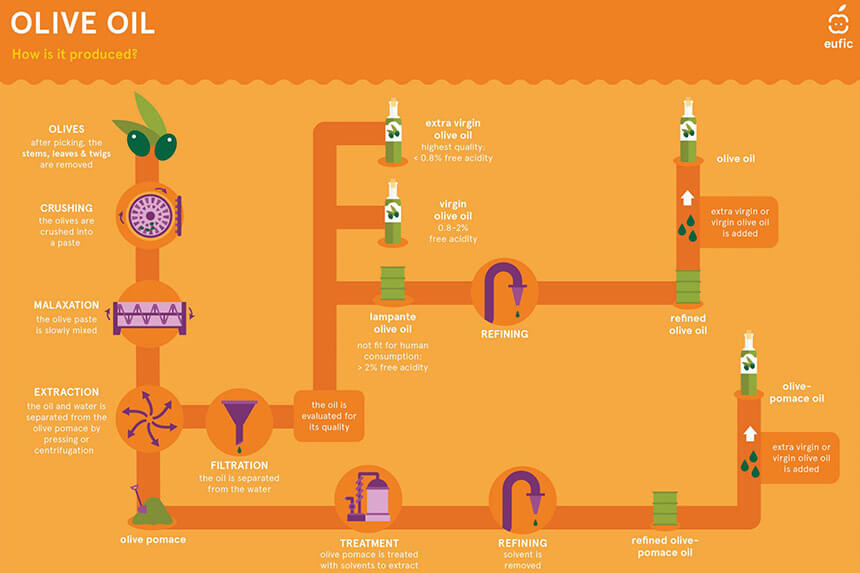

Olive oil is extracted from olive fruits. To retain flavor, aroma and nutrients, go through four stages: cleaning, pressing, refining and storage. Different machines are used in each stage. The following are main equipment used in olive oil production process and functions.

Olive Cleaning Equipment

Receive Hopper and Conveyor Belt

Receives delivered olive fruits and transports them via conveyor belt to subsequent processing equipment, ensure continuous production.

Remove Leaf Machine

Removes leaves, small branches, and other impurities mixed with olive fruits. Typically use blower or vibrating screen for separation. These impurities can affect olive oil quality.

![Olive cleaning machine Olive cleaning machine]()

Olive Cleaning Machine

Washing olive fruits with water, remove surface contaminants such as soil, dust, pesticide residues and small pebbles. Typically include spraying, soaking and brushing. After washing, olive fruits are usually drained.

Slicing Machine

The slicing machine cuts olive fruits into small pieces, then feed into crusher for further processing.

Olive Oil Press Machine

Olive Crusher

Crusher breaks down sliced olive fruits (flesh and pits) into paste-like substance. This is key step in extract olive oil. The common crushers are hammer crusher and disc crusher.

- Hammer crusher: Use high-speed rotate hammers crush olive fruits.

- Gear disc crusher: Imitate traditional stone mill, use two metal discs with tooth patterns rotating in opposite directions to grind fruits. This can better control crushing degree, reduce bitterness caused by over-crushing of pits.

![Olive oil press machine Olive oil press machine]()

Olive Oil Hydraulic Press Machine

Apply mechanical pressure (usually 300-400 tons) to crushed olives, slowly squeeze out mixed oil. (You may also be interested in: Huatai Oil Pressing Machines >>)

This process require staged pressure increases, avoid high temperatures and excessive oxidation.

Crude Olive Oil Storage Tank

Receive oil-water mixture (referred to as “crude oil”) seep from hydraulic press, temporarily store it, and prepare it for refining.

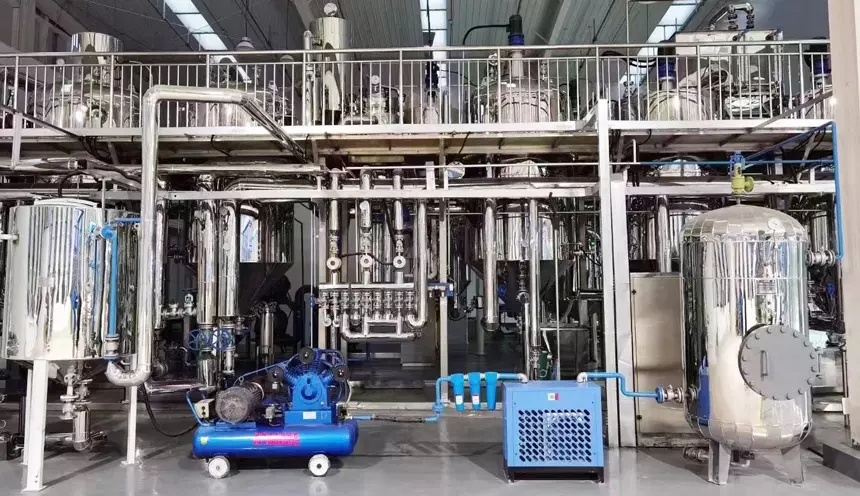

![Olive crude oil refining machine Olive crude oil refining machine]()

Crude Olive Oil Refining Machines

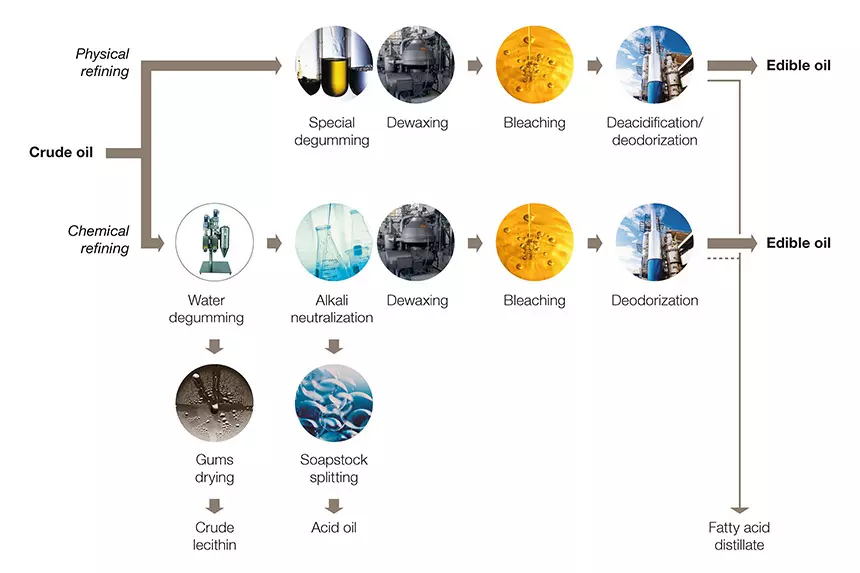

Crude Olive oil obtained through hydraulic pressing has high free fatty acid content, high impurity levels, poor flavor and texture, and instability. It must through refining (degumming, neutralization, decoloring and deodorization), become safe-to-consume olive oil.

The refining process requires a series of specialized equipment: centrifuge, neutralization tank, decolorization tank, filter, deodorization tower, etc.

Degumming Equipment

Degumming is to remove phospholipids, gums, some proteins, and metal ions. These can cause oil emulsification, cloudiness, and when heat produce foam and black sediment.

First, add hot water (or dilute acid/alkali) to stirring tank, cause hydrophilic colloids absorb water, swell and coagulate.

Then, use disc centrifuge to separate coagulated gums from degummed oil.

![Olive oil neutralization tank in refinery plant Olive oil neutralization tank in refinery plant]()

Neutralization/Deacidification Equipment

Neutralization is to remove free fatty acids (FFA), residual gum, pigments, and oxidation products from olive crude oil. The machine used is as follows:

- Mixing reaction tank: Add precisely measured alkali solution (typically sodium hydroxide) to react with FFA, produce soap residue.

- Centrifugal separation: Use high-speed disc centrifuge to separate soap residue from neutral oil.

- Water wash tank: Use hot water wash neutral oil to remove residual soap particles and alkali.

- Centrifugal separation/drying: Centrifugally separate wash water again, use vacuum drying tower to remove trace moisture from oil.

Tips: Precisely control alkali amount and concentration to minimize neutral oil loss.

![Olive oil decolorization tank in refinery plant Olive oil decolorization tank in refinery plant]()

Decolorization Equipment

Decolorization can remove pigments (chlorophyll, carotenoids), trace metals, residual soap particles and oxidation products. The machines used in this step are decolorization tanks and filters.

Decolorization tank(with stirring and vacuum): Under vacuum and moderate heating (about 90–110°C), add an adsorbent (active white clay, sometimes with activated carbon) and stir.

Filtration System: Use plate frame filter or leaf filter to thoroughly remove waste white clay and its adsorbed impurities. The filtered oil must be cooled.

![Olive oil deodorizing tower in refinery plant Olive oil deodorizing tower in refinery plant]()

Deodorization Equipment

Deodorization can remove volatile odor-causing substances (aldehydes, ketones, hydrocarbons, etc.), residual free fatty acids, solvents and pesticide residues. Simultaneously destroy peroxides to enhance oxidative stability.

The core equipment used in deodorization process is deodorization tower. Under high vacuum (absolute pressure <5 mbar) and high temperature (180–240°C), high-temperature steam (stripping steam) is introduced into olive oil. Volatile substances are carried away by the steam.

Complete deodorization tower typically includes degasser, heater, deodorization tower body, fatty acid collector, vacuum system and cooler.

Tips: High temperatures can easily produce trans fatty acids and glycerol esters (GEs), so must strictly control process parameters.

![Olive oil processing plant Olive oil processing plant]()

Olive Oil Storage Tank

Used to store refined olive oil. The materials and conditions for storage tank are as follows:

- Material: Food-grade stainless steel (304 or 316L), to avoid reaction with oil or odor.

- Inert gas protect: Inject into tank with inert gas such as nitrogen, exhaust oxygen and prevent oil oxidation and rancidity.

- Light protect: Place tank in dark room or designed to be light-resistant, to prevent oxidation caused by light.

- Temperature control: The storage environment temperature is typically maintained around 15–18°C, to avoid high temperature accelerating oxidation.

Conclusion

In general, olive oil extraction process include cleaning, pressing, refining and storage. Each stage uses different machines.

Henan Huatai Intelligent Equipment Group specializes in design and manufacture olive oil extraction machine and has many years of experience in setting up olive oil processing plant and production line. For more information about olive oil processing, please feel free to contact us.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ