Introduction

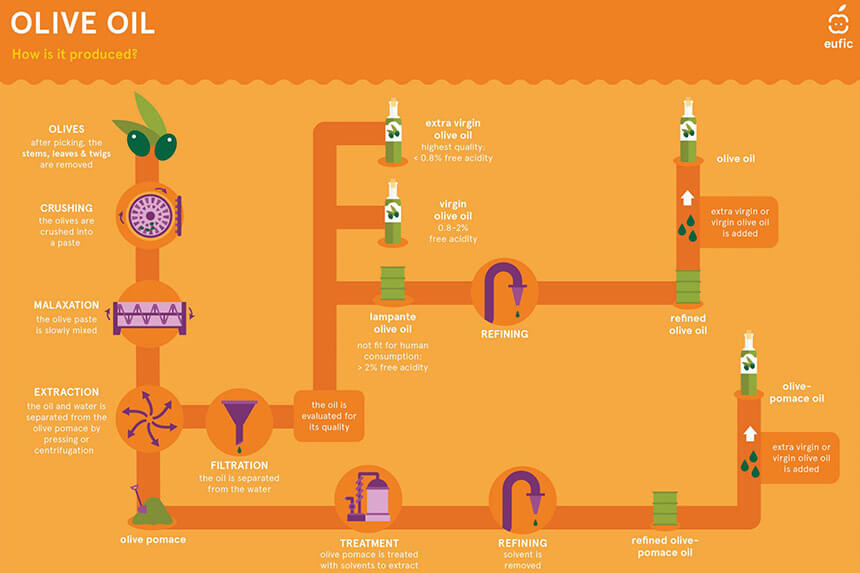

The olive oil refining process use physical and chemical methods to convert virgin olive oil into neutral, versatile olive oil.

This article explores processing of refined olive oil, its health impacts, machinery used, and setup an olive oil refinery plant cost.

Whether you are considering buying an olive oil refining machine or setting up an olive oil refinery plant, Henan Huatai Intelligent Equipment Group can provide you with professional and customized solutions, ensuring efficient and low cost.

What is Refined Olive Oil?

Refined olive oil is olive oil that has through chemical and physical processing to remove impurities, off-flavors, and undesirable components.

The International Olive Council defines refined olive oil as oil extracted from virgin olive oil by refining process. This process does not change olive oil's initial glycerol structure.

This oil typically has free fatty acid content of less than 0.3%. It is colorless, odorless, and tasteless in appearance.

![What is refined olive oil What is refined olive oil]()

Is Refined Olive Oil Still Healthy?

Refined olive oil loses many healthful compounds during refining process, such as polyphenols, antioxidants, and vitamins. However, it still has following benefits:

- Contain heart-healthy monounsaturated fats

- Have higher smoke point than extra virgin olive oil

- Provide essential fatty acids

- Stability at higher cooking temperature

In short, compared to animal fats and other vegetable oils, refined olive oil still safe and nutrient-rich. But its health benefits are not as good as fresh cold-pressed olive oil.

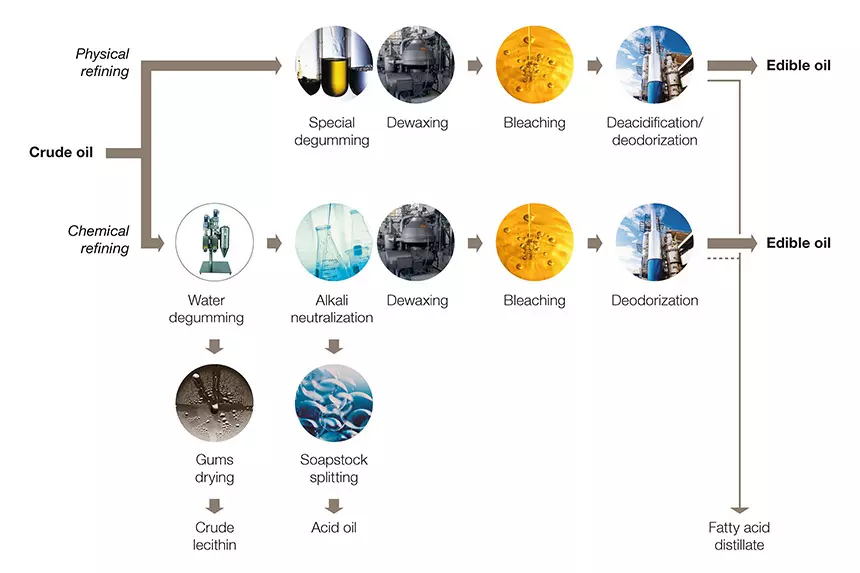

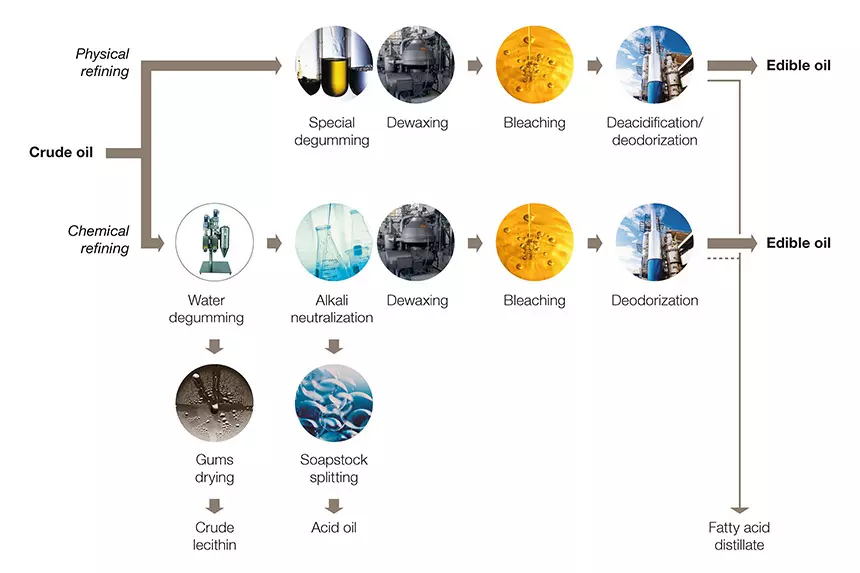

What is Olive Oil Refining Process?

The olive oil refining process involves four main steps: deguming, deacidification, decolorization and deodorization. Each step removes specific impurities and odors, preserving oil's basic structure and fatty acid composition.

Degumming

Degumming removes olive oil phospholipids, proteins, gums, and other impurities.

The process heat olive oil to 70-80°C and add 2-3% water or diluted phosphoric acid. Then, high-speed centrifugation separates gums and phospholipids from olive oil.

The degumming process typically reduces phosphorus content to less than 10 ppm, ensure better oil stability. (Related Post: palm oil degumming process >>)

![Olive oil neutralization tank Olive oil neutralization tank]()

Deacidification/Neutralisation

The deacidification process removes free fatty acids, reduces rancidity and off-flavors.

Heat olive oil to 85-90°C and mix with caustic soda or an alkaline solution. The chemical reaction produce soap base, separated from oil through centrifugation. The deacidification process reduces free fatty acid content to below 0.3%.

After deacidification, wash olive oil with hot water to remove soap base residues and excess alkali. This step requires precise temperature and pH control to prevent over-neutralization, result in oil loss. (Related Post: palm oil deacidification process >>)

![Olive oil decolorization tower Olive oil decolorization tower]()

Decolorization/Bleaching

Decolorization removes colored compounds, chlorophyll, and carotenoids that affect olive oil color and stability.

This process use activated bleaching earth or activated carbon at 85-120°C under vacuum conditions.

The olive oil refining machine mixes olive oil with 0.5-2% bleaching earth for 15-30 minutes. Then, filtration removes spent bleaching earth along with adsorbed impurities. (Related Post: palm oil bleaching process >>)

![Olive oil deodorization tower Olive oil deodorization tower]()

Deodorization

Deodorization removes odors and volatile compounds, resulting in a neutral flavor.

Heat olive oil to 210-220°C under vacuum conditions, then steam distill to remove volatile odors, aldehydes and residual free fatty acids.

This process needs temperature control to prevent thermal degradation of olive oil. (Related Post: palm oil deodorization process >>)

![Pure olive oil and refined olive oil Pure olive oil and refined olive oil]()

What is Difference Between Pure Olive Oil and Refined Olive Oil?

Pure olive oil and refined olive oil are different products with different characteristics:

| Attribute |

Pure Olive Oil |

Refined Olive Oil |

| Composition |

Blend of refined oil + 15–25% extra-virgin |

100% refined oil |

| Free acidity (max) |

1.0% |

0.3% |

| Flavour |

Mild olive notes |

Neutral, almost tasteless |

| Smoke point |

200 – 215 °C |

230 °C + |

| Main use |

Everyday stir-frying, baking |

High-heat frying, mayonnaise |

| Nutrient density |

Higher polyphenols than refined alone |

Lowest polyphenols |

What is Better, Refined or Unrefined Olive Oil?

Unrefined olive oil (extra virgin) typically has better health benefits and flavor than refined olive oil. The choice depends on use and personal preference.

![Refined and unrefined olive oil Refined and unrefined olive oil]()

Unrefined (Extra Virgin) Olive Oil Benefits

- Rich antioxidants and polyphenols

- Distinctive flavor and aroma

- Higher vitamin E content

- Anti-inflammatory properties

- No chemical processing

Refined Olive Oil Benefits

- Higher smoke point for cooking

- Neutral flavor for baking

- Longer shelf life

- Lower cost

- Consistent quality

Refined olive oil is better for high-heat cooking, baking, and neutral flavor applications. Unrefined olive oil more suitable for salad dressings, finishing dishes, and low-heat cooking.

![Olive oil refining machine Olive oil refining machine]()

What Machines are Used in Olive Oil Refining Process?

The olive oil refining process relies on specialized olive oil refining machines to ensure efficiency and quality. Key equipment includes:

Acid or enzymatic mixers and disc-stack centrifuges for degumming.

Neutralization tank with lye dosing and centrifugal separators.

Bleaching tank fitted with vacuum pumps, clay dosing screws and leaf filters.

High-vacuum deodorization tower with steam injectors, packed trays, and heat recovery exchangers.

PLC automation system with auxiliary pumps, plate heat exchangers, nitrogen blanketing, and temperature and vacuum control.

Henan Huatai Intelligent Equipment Group olive oil refinery plant have three types: batch type (1–20 tons/day), semi-continuous type (20–50 tons/day), and full-continuous type (>50 tons/day). Please feel free to contact us or visit our factory at any time!

![Olive oil refinery plant cost Olive oil refinery plant cost]()

How Much Set up an Olive Oil Refinery Plant?

The cost of set up an olive oil refinery plant based on capacity, equipment specifications, brand and others. As show in table below:

| Type |

Capacity |

Equipment Cost |

Initial Cost |

| Batch-type |

1-20 ton/day |

$50,000-$250,000 |

$100,000-$500,000 |

| Semi-continuous type |

20-50 ton/day |

$250,000-$600,000 |

$500,000-$1.2 million |

| Full-continuous type |

>50 ton/day |

$600,000-$1 million |

$1.2-10 million |

Additional costs include:

- Land and building construction

- Utilities and infrastructure

- Permits and regulatory compliance

- Working capital for operations

- Staff training and certification

Energy-efficient equipment reduces operate cost, but needs higher initial investment. Location factors, labor costs, utilities, and transportation access affect total project economics.

Conclusion

The olive oil refining process removes impurities, improves color, odor, and taste, and reduces acidity of olive oils through degumming, deacidification, decolorization, and deodorization.

Selecting right olive oil refining machine and sizing olive oil refinery plant needs balancing capacity, automation, and budget.

Henan Huatai Intelligent Equipment Group olive oil extraction machine provide efficient, automated processing that meets international quality standards. Our olive oil processing plant maximizes yield and profitability. Please feel free to contact us for more information or to visit our factory!

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ