Introduction

Olive oil production process is designed to maximize olive fruit flavor, aroma and nutritional content. This guide explores olive oil making process each step, from harvest to filling.

Whether you are planning to transform exist olive oil processing plant or want to start olive oil business, Henan Huatai Intelligent Equipment Group can provide best solution. We have a professional team of engineers, ensure produce high-quality olive oil.

Step 1: Olive Harvest

Olives are usually picked by hand or machine (shaker) in early maturity stages, turn from green to purple or black. This process take place in fall each year. At this time, olives have high oil content, rich polyphenols and best flavor.

During harvesting, try to avoid olives falling to ground and getting damaged. Because fallen fruits are easily oxidized, contaminated by soil and microorganisms, resulting decrease oil quality (high acidity and odor). Also avoid damaging the branches.

![Olive harvest Olive harvest]()

Step 2: Olive Transport

Since olives deteriorate exposed to high temperatures or humid environments, they must transport to processing plant as soon as possible (within 24 hours, and no later than 48 hours) after harvesting.

During transport, olives should place in well-ventilated crates or large mesh bags, prevent piling up, generating heat and fermentation.

![Olive transport Olive transport]()

Step 3: Deleafing and Cleaning

Before processing, olives must be defoliated and washed. Removing leaves, branches, soil and other impurities, ensure quality of olive oil and protect machines used later.

Defoliation/Debranching

Use blower or vibrating screen to remove leaves, small branches, and other impurities. Chlorophyll in leaves can impart bitter and grassy taste.

In small scale factory, this may need to be done manually.

Cleaning

After defoliation, sent olives to washing machine. Thoroughly rinsed with water to remove soil, dust, pesticide residues, small stones, etc.

![Olive cleaning Olive cleaning]()

Step 4: Slicing and Crushing

After cleaning, olives are sliced and crushed, break down flesh and release oil.

Slicing

Some modern olive oil processing equipment is equipped with slicer, it can cut olives into small pieces. This step makes pressing process more efficient.

Crushing

Use hammer crusher or disc crusher to crush olives. The degree of crushing should be moderate.

Over crushing may result in overly fine pulp, making subsequent separation difficult, and potentially leading to excessive extraction and bitterness; insufficient crushing reduce oil yield.

Additionally, must avoid high temperatures during crushing (typically below 30°C) to prevent thermal damage.

The result paste is a mixture of oil, water, and solids, ready for separation in next step of olive oil extraction process.

![Olive oil centrifugal separation process Olive oil centrifugal separation process]()

Step 5: Pressing or Centrifugal Separation

Separate oil from paste is key step in olive oil manufacturing process. Use two methods: pressing and centrifugal separation.

Pressing Method

Use hydraulic press or screw press apply great pressure to olive paste, squeeze out olive oil and juice to form mixture. (You may also be interested in: Oil pressing machine >>)

The mixture then subjected to sedimentation or centrifugation for oil-water separation.

Centrifugal Separation Method

First is liquid-solid separation. Pump olive paste into high-speed rotating horizontal screw centrifuge (Decanter). Under centrifugal force, olive paste is separated into three parts based on density:

- Pomace: The heaviest solid part (pulp and stone pieces), discharged from one end of centrifuge.

- Juice (Vegetation Water): The water phase (containing water-soluble substances, sugars, organic acids, etc.), discharged from the middle.

- Oil-water mixture: A mixture of lighter oil phase and a small amount of water phase, discharged from the other end.

Then is liquid-liquid separation (oil-water separation). Pump oil-water mixture obtained before into vertical centrifuge (Disc Stack Centrifuge/Oil Purifier).

Under centrifugal force, lighter oil phase is completely separated from denser water/impurity phase. Pure olive oil flows out through central tube, water phase (containing a small amount of oil foam) discharged from periphery.

![Small scale olive oil refining plant Small scale olive oil refining plant]()

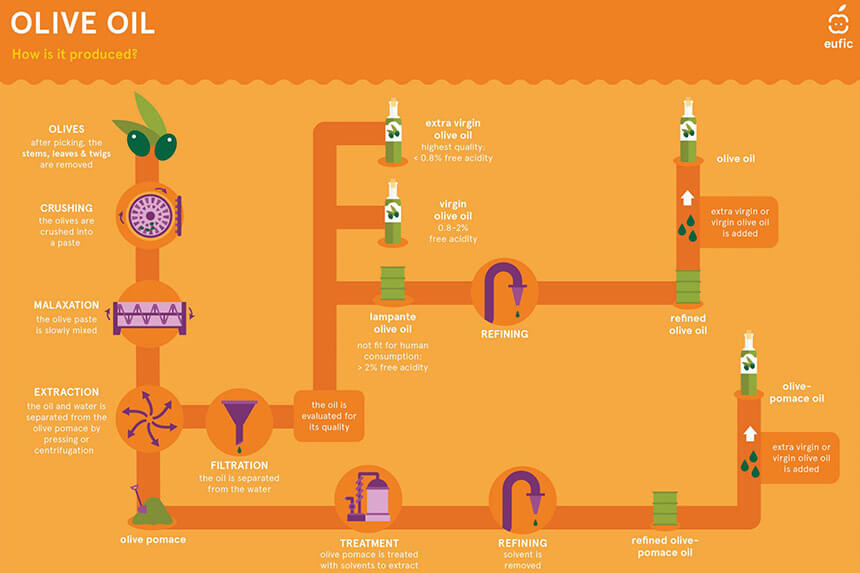

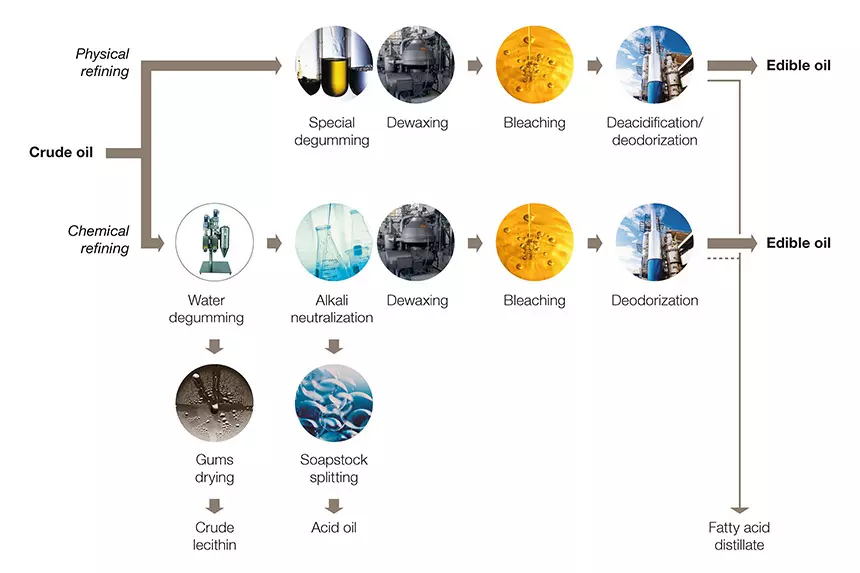

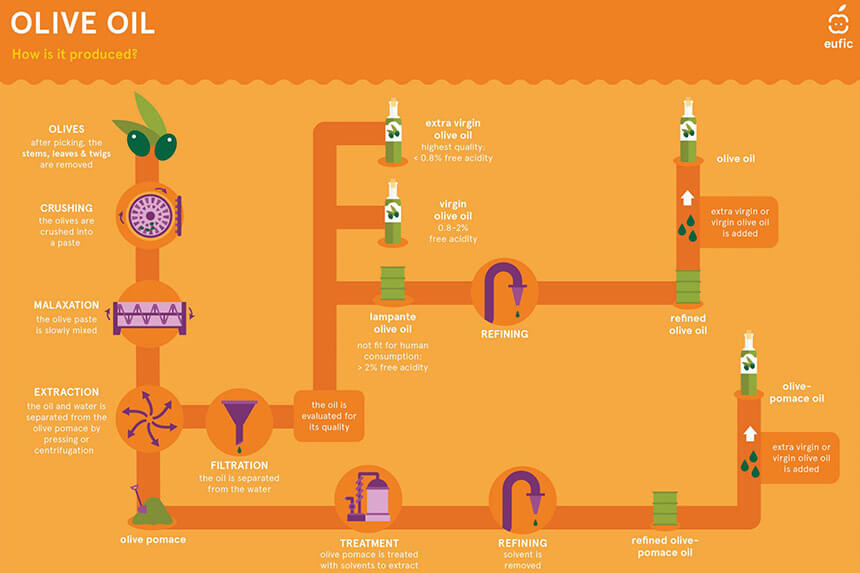

Step 6: Refining (Optional)

Refining is optional step in process of producing olive oil, usually used for lower quality olive oils. It includes neutralization, bleaching and deodorization, to remove impurities, off-flavors, and acidity.

Extra virgin olive oil, prized for its natural flavor and health benefits, is usually not refined.

Refining can extend shelf life of olive oil, but may reduce its nutritional value.

Step 7: Storage and Filling

Whether small olive oil mill or large olive oil processing plant, storage and filling ensure olive oil retains flavor and nutritional value.

Storage: After extraction, pump olive oil into food-grade stainless steel storage tanks. This protect oil's quality, stabilizes flavor, and slows down oxidation process.

Storage conditions:

- Light protection: Prevent light-induced oxidation.

- Sealing: Isolate oxygen.

- Inject nitrogen: Inject nitrogen into top space of tank, displace oxygen and prevent oxidation.

- Control temperature: Store in a cool, temperature-controlled environment (typically 15–18°C).

Filling: Olive oil is transported from storage tank via pipelines to automated filling line. Then fill into dark glass bottles, food-grade metal cans, or specially light-protected PET plastic bottles.

Dark container minimize contact between high-quality olive oil and air and light.

![Olive oil storage and filling Olive oil storage and filling]()

Conclusion

The above is olive oil processing plant complete process. Modern equipment not only improve efficiency but also maintains excellent olive oil quality.

Henan Huatai Intelligent Equipment Group has advanced olive oil processing equipment, improve olive oil production process efficiency and control quality.

Whether you want to process extra virgin olive oil or refined olive oil, our olive oil extraction machine can meet your requirements. Feel free to contact us for more details!

Frequently Asked Questions

What is the best method of extraction olive oil?

Centrifugal separation is best method for extracting olive oil. It’s efficient, yields 85-90% oil. This method yields high-quality oil with good flavor and antioxidants, is efficient and continuous, popular than traditional pressing.

How much olive oil from one tree?

A mature olive tree (20+ years) produces about 20 to 40 liters oil per season under ideal conditions. Young trees yield less, around 5 to 10 liters. Oil yield depends on olive variety, climate and cultivation. About 4 to 5 kg olives produce 1 liter oil.

How ripe should olives be for oil?

Olives for extra virgin olive oil should be harvested at ripeness levels 5-6, they’re black with partially purple flesh. Overripe olives increase acidity, reduce quality, underripe yield less oil.

How long does expensive olive oil last?

High-quality extra virgin olive oil lasts about 18 to 24 months if stored properly. Once opened, use within 2-3 months to enjoy optimal flavor and nutritional benefits.

How much does olive oil processing plant cost?

The cost of olive oil processing plant varies widely based on capacity and technology. From $50,000 for small-scale equipment to over $1 million for large automated facilities.

References:

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ