Introduction

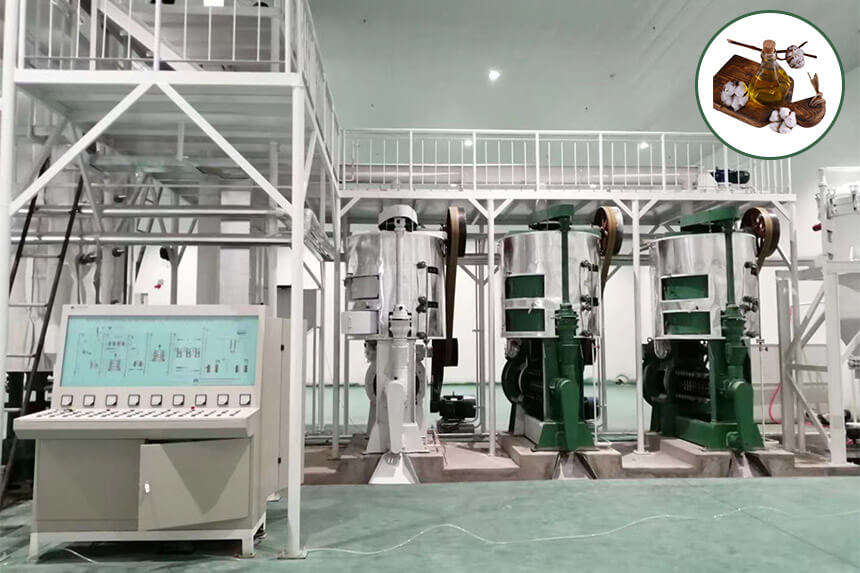

The global edible oil industry continues to expand, and cottonseed oil represents one of the most promising segments for processors and investors.

Henan Huatai Group specializes in designing and implementing efficient cottonseed oil mill plants tailored to your specific needs and budget.

Whether you're planning to establish a new processing facility or upgrade existing equipment, understanding the complete production process helps you make informed decisions.

What is Cottonseed Oil?

Cottonseed oil is a vegetable oil extracted from cotton seeds and ranks among the world's primary edible oils. Crude cottonseed oil contains substances like gossypol and appears darker red than other oils. It must go through refining to be safe for consumption.

Research shows, refined cottonseed oil contains rich necessary fatty acids for the human body. For example: palmitic acid (21.6-24.8%), stearic acid (1.9-2.4%), oleic acid (18.0-30.7%), and linoleic acid (44.9-55.0%).

The linoleic acid in refined cottonseed oil effectively inhibits cholesterol elevation in the blood, promoting human health. The human body achieves a 98% digestion and absorption rate for cottonseed oil, making it ideal for mixing with animal fats in consumption.

![Cottonseed oil production process flow chart Cottonseed oil production process flow chart]()

What Is Cottonseed Oil Production Process?

Cottonseed Pretreatment

Cotton seed pretreatment is fundamental to ensuring oil yield and quality, including the following steps:

- Delinting: A cottonseed delinting machine removes short lint (<3mm) from the cottonseed surface. These can produce chemical fibers and nitrocellulose. Delinting must strictly control equipment speed and clearance, achieve a delinting rate above 95% while keeping the damage rate below 5%.

- Cleaning: Cleaning screens removes impurities such as dirt and small stone particles.

- Dehulling and shell-kernel separation: Impact dehullers or knife-plate dehullers remove the cottonseed shell. Then gravity screens and air separation systems separate the shells from the kernels, ensuring the kernel contains less than 8% shell content.

- Flaking: A double-roller flaking machine rolls the cotton kernels into uniform thin flakes measuring 0.25-0.30mm. This process destroys cell structures and increases surface area, promoting steaming and pressing.

- Cooking: A multi-layer vertical steaming and cooking pot treats the cottonseed flakes, adjusting temperature (105-110°C) and moisture content (5%-8%) to prepare them for pressing.

![Cottonseed oil expeller machine for sale Cottonseed oil expeller machine for sale]()

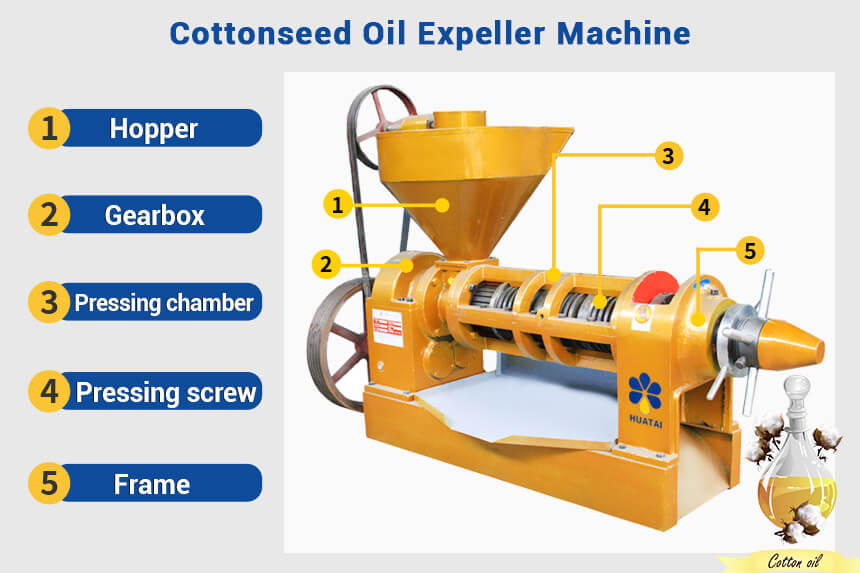

Cottonseed Oil Pre-Pressing

Using a screw oil press machine extracts oil from the pretreated cottonseed. The machine consists mainly of a hopper, gearbox, pressing chamber, screw shaft, and press bars. The screw shaft and press bars are made from alloy steel with carburization treatment to prevent damage from cottonseed's high abrasiveness.

Then, pass the crude oil through a plate-and-frame filter or horizontal leaf filter to remove 80% of solid cake residue. They quickly cool the filtered crude oil below 60°C to prevent color darkening and quality deterioration.

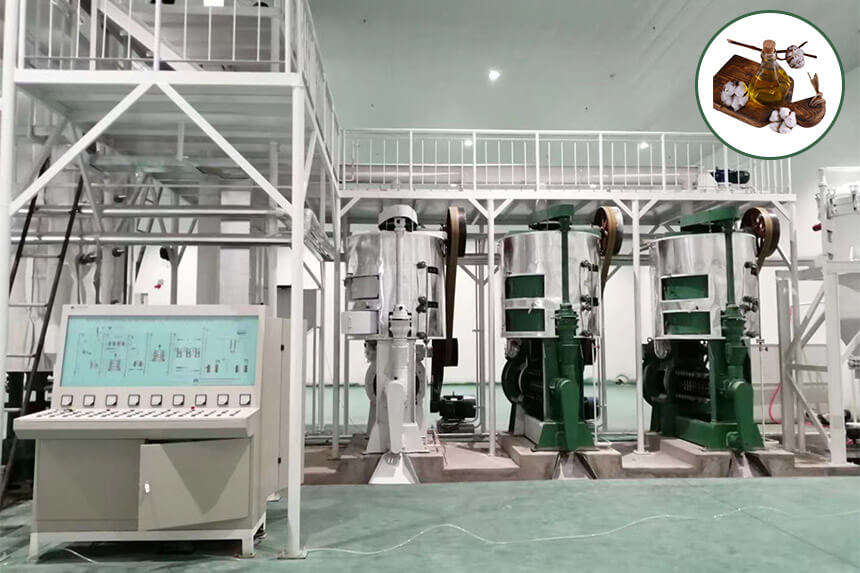

Cottonseed Cake Solvent Extraction

Pre-pressed cottonseed cake still retains 12%-18% residual oil. Solvent extraction reduces this to below 1%.

- Solvent extraction: Using n-hexane as the solvent in rotocel extractors or loop extractors. Through countercurrent extraction principles, dissolves almost all residual oil from the cake, forming mixed oil (oil-solvent mixture).

- Wet meal desolventizing: The DTDC (Desolventizer-Toaster-Dryer-Cooler) system removes residual solvent and moisture, minimizing protein denaturation (protein content >50%). And reduces free gossypol content below 400mg/kg, producing safe high-protein animal feed.

- Evaporation and stripping: First, a rising film evaporator concentrates the mixed oil from 20-25% to 90-95%. Then a disc stripping tower uses direct steam under vacuum to completely remove residual solvent, producing extracted crude oil with solvent residue below 50ppm.

- Solvent Recovery: A condenser liquefies all evaporated solvent vapors. After a water separator removes moisture, the pure solvent returns to the solvent storage tank for reuse. Solvent consumption below 5kg per ton of raw material, reducing production costs.

![Cotton seed oil solvent extraction plant Cotton seed oil solvent extraction plant]()

Cottonseed Oil Refining

Crude cottonseed oil contains gossypol (about 1%), gums, and waxes, making it poor quality and unsafe for direct consumption. After refining, the cottonseed oil contains less than 0.02% gossypol, meeting food safety standards. The cottonseed oil refining process includes the following steps:

- Degumming: Add phosphoric acid (0.02% of oil weight) to remove phospholipids and gums from the oil.

- Neutralization: Add alkali solution (NaOH) reacts with free fatty acids to form soapstock. Then, heat and centrifuge to remove soapstocks.

- Bleaching: Adsorbents (e.g., white clay) remove pigments. Add 2% bleaching earth (by oil weight) each time and perform bleaching twice continuously at 105°C under 0.098 MPa vacuum.

- Deodorization: High-temperature vacuum distillation at 210°C and 1 kPa vacuum removes odor substances such as aldehydes and ketones.

![Cotton seed oil refining process flow chart Cotton seed oil refining process flow chart]()

Cottonseed Oil Fractionation

Cottonseed oil fractionation utilizes the melting point differences among various triglycerides in cottonseed oil. Through controlled crystallization and filtration, separate the oil into liquid oil and solid stearin. The semi-continuous dry fractionation process for cottonseed oil follows: (Related Post: Palm oil fractionation plant >>)

First, slowly cool the deodorized cottonseed oil in crystallization tanks (from 50°C to 15°C at a rate of 5°C per hour) with gentle stirring. This promotes stable, large crystal formation from high-melting-point triglycerides.

Then, maintain the target temperature for a period to stabilize the crystal structure.

Finally, a high-pressure membrane filter press (25 bar pressure) performs solid-liquid separation, yielding clear liquid oil and solid stearin.

- Liquid oil: Clear and transparent when refrigerated, as a premium salad oil and cooking oil.

- Solid stearin: Natural and zero trans-fatty acids, as a base oil for margarine and shortening, with value far exceeding standard refined oil.

Cottonseed Oil Processing Plant Investment Cost Analysis

Below are investment cost estimates for cottonseed oil processing plants of different scales:

| Production Scale |

Equipment Investment |

Plant and Facilities |

Total Investment |

| 1-10 tons/day |

$150,000-500,000 |

$100,000-300,000 |

$250,000-800,000 |

| 10-50 tons/day |

$500,000-2 million |

$300,000-1 million |

$800,000-3 million |

| 50-100 tons/day |

$2-4 million |

$1-2.5 million |

$3-6.5 million |

Investment Reference: The cottonseed pressing project in Yueyang Lingang High-tech Industrial Development Zone required a total investment of about $74 million, with a construction area of 53,815.89 ㎡ and a land area of 120 acres (about 8 hectares).

Global Cottonseed Oil Producing Countries Ranking

According to QYResearch survey statistics, the current status of the global cottonseed oil industry shows:

| Country |

Annual Production (10,000 MT) |

Global Share |

| India |

124 |

25% |

| China |

87 |

17.5% |

| Pakistan |

87 |

17.5% |

| United States |

25 |

5% |

| Brazil |

20 |

4% |

| Uzbekistan |

15 |

3% |

| Turkey |

12 |

2.4% |

| Australia |

10 |

2% |

| Argentina |

8 |

1.6% |

| Greece |

7 |

1.4% |

Global Market Size: QYResearch statistics, the global cottonseed oil market sales will reach RMB 52.45 billion by 2031, with a compound annual growth rate (CAGR) of 3.3% (2025-2031). Major global cottonseed oil manufacturers include ADM, Bunge, Louis Dreyfus, PYCO Industries, and N.K. Proteins. The top five global manufacturers collectively hold about 10% of the market share.

Conclusion

Investment cottonseed oil mill plant delivers reliable returns on. From small 10 ton daily capacity plants to large industrial facilities processing 500+ tons daily, all can achieve rich profits.

Henan Huatai Group provides cotton seed oil production line comprehensive turnkey solutions including equipment selection, plant layout design, installation supervision, operator training, and ongoing technical support. Contact us today for a free consultation and customized quotation.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ