Introduction

Cottonseed oil fractionation technology transforms refined cottonseed oil into liquid olein and solid stearin to meet the diverse needs of today's market.

In this guide, I will walk you through everything you need to know about cottonseed oil fractionation.

What Is Fractionated Cottonseed Oil?

Fractionated cottonseed oil is a product obtained through dry fractionation of refined cottonseed oil. This process is a further physical separation step beyond refining. By controlling temperature changes to separate cottonseed oil into liquid olein (soft fat) and solid stearin (hard fat), enabling functional applications of the oil. (Related Post: Fractionated coconut oil process >>)

The fractionation process alters the fatty acid composition of both liquid oil and solid stearin according to temperature changes. The liquid oil shows a significantly higher proportion of unsaturated fatty acids (such as linoleic acid and oleic acid).

![Cottonseed oil fractionation process Cottonseed oil fractionation process]()

What Is the Cottonseed Oil Fractionation Process?

Cottonseed oil fractionation, also known as dry fractionation, relies on the differences in melting points and solubility among various triglycerides in cotton seed oil. Through controlled cooling crystallization and solid-liquid separation, it separates liquid oil (Olein) from solid stearin (Stearin). The complete process includes four key steps:

Step 1: Cottonseed Oil Melting and Heating

Heat refined cottonseed oil in a crystallization tank to 50-60°C, and keep this temperature with continuous stirring for at least 30-60 minutes.

This step destroys the original crystal structure in the oil, ensuring all lipid components melt completely and reach a uniform state. Ensures the formation of uniform, stable, and easily filterable crystals.

If don't completely clear up the original crystal structure, cooling will result in poor crystal formation and excessive oil entrapment, which affects separation efficiency.

![Henan Huatai Group edible oil crystallization tank Henan Huatai Group edible oil crystallization tank]()

Step 2: Cottonseed Oil Cooling Crystallization

First, cool the melted cottonseed oil at a relatively fast rate (5-10℃ per hour) to 30-35℃. At this point, high-melting-point triglycerides begin reaching saturation and prepare to form crystal nuclei.

Then, once the temperature reaches the crystallization point, must reduce the cooling rate (0.5-3℃ per hour).

Finally, after reaching the final temperature, continue slow stirring for 4-12 hours to ensure stable and uniform crystal structure, facilitating solid-liquid separation.

To get more and clearer liquid oil, a lower final temperature (e.g., 15-20℃); to get more stearin, use a higher final temperature.

Step 3: Cottonseed Oil Solid-Liquid Separation

After crystal growth is complete, separate the crystallized oil slurry (a mixture of liquid oil and solid stearin crystals) at low temperatures of 15-25℃. The main equipment used includes vacuum filters or membrane filter presses.

Vacuum Filter: This system uses vacuum suction for filtration and requires extremely stable and uniform β' crystals. Its advantages include continuous feeding and high automation.

Membrane Filter Press: After filtration, this system applies controlled pressure (0.4-1.5 MPa) to the filter cake. By pressing filter cake, extract additional liquid oil trapped in crystals, increasing liquid oil yield by more than 5% and producing stearin with lower oil content.

Solid-liquid separation directly determines the yield and quality of cottonseed oil fractionation products, finally producing liquid cottonseed olein and solid cottonseed stearin. (Related Post: Fractionated palm kernel oil >>)

![Cottonseed oil solid-liquid separation equipment Cottonseed oil solid-liquid separation equipment]()

Step 4: Liquid Oil and Solid Stearin

- Liquid Oil (Cottonseed Olein): Rich in unsaturated fatty acids, has high smoke and flash points with good oxidation stability. It is an excellent frying oil and base oil for salad oils, while also adding unique flavor to foods.

- Solid Stearin: With a higher melting point, as raw material for shortening and margarine in pastry and cookie processing to create crispy textures in foods.

What Factors Affect Cottonseed Oil Fractionation?

- Crystallization temperature: Different target products require different final crystallization temperatures.

- Cooling Rate: Cooling too quickly produces small crystals that trap excessive oil, affecting filtration efficiency and liquid oil yield. Slow cooling helps form large, stable crystals.

- Raw material quality: The fatty acid composition of cottonseed oil directly impacts fractionation results. Cottonseed oil contains about 21.6%-24.8% palmitic acid, and this content determines stearin yield. If crude oil contains too many impurities, they will interfere with crystal formation. Therefore, cottonseed oil refining quality is the basis for fractionation.

- Stirring intensity: During crystallization, moderate stirring enables uniform crystal growth and prevents crystal clumping. Excessive stirring can destroy formed crystals.

- Filtration process and additive use: Must precisely control pressure and temperature during filtration. Sometimes, to improve filtration efficiency, add appropriate amounts of filter aids (such as diatomaceous earth), which form loose filter cakes, improving filtration rate and liquid oil clarity.

Fractionated vs Refined vs Crude Cottonseed Oil

The table below provides a detailed comparison of fractionated, refined, and crude cottonseed oil across processing methods, physical properties, and chemical characteristics:

| Model |

Fractionated cottonseed oil |

Refined cottonseed oil |

Crude cottonseed oil |

| Processing Steps |

After crude oil refining, further physical fractionation processes, including heating, temperature-controlled crystallization, and filtration. |

Through chemical/physical refining steps such as degumming, neutralization, bleaching, and deodorization. |

Cotton seeds through direct pressing or solvent extraction, without refining treatment. |

| Appearance |

Liquid oil is clear and transparent; stearin is a white solid. |

Light yellow, transparent. Prone to crystallization under cold conditions, forming a partially white solid block. |

Dark in color, appearance is cloudy. |

| Smoke Point |

Liquid oil: ≥220℃ |

≥210℃ |

About 160-180℃ |

| Freezing Point |

Liquid oil: -5-0℃; Solid stearin: 30-40℃ |

About 0-5℃ |

None |

| Fatty Acid Composition |

Liquid oil has a higher content of unsaturated fatty acids; stearin is enriched with saturated fatty acids. |

It possesses the natural fatty acid composition of cottonseed oil, such as linoleic acid content of 44.9%-55.0%. |

Similar to refined cottonseed oil, but impurities affect its stability. |

| Gossypol Content |

None |

<0.02% |

About 1%, rich in free gossypol. |

| Stability |

Liquid oil has good oxidative stability. |

Good oxidative stability. |

Due to impurities, prone to oxidative rancidity. |

| Main Uses |

Liquid oil: premium salad oil, frying oil; Stearin: shortening, margarine, cocoa butter substitute. |

Ordinary cooking oil, also used as a raw material for producing salad oil, margarine, and shortening. |

Not for direct consumption, used only as a raw material for industrial oils. |

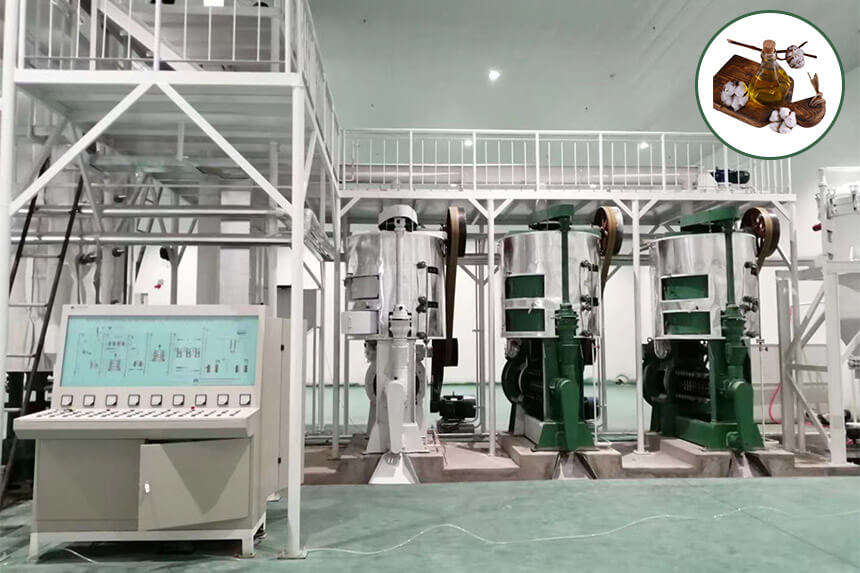

Cottonseed Oil Fractionation Plant Investment Cost Analysis

The cost of setting up a cottonseed oil fractionation plant depends on factors such as processing scale, automation level, and equipment manufacturer. Below are cost estimates for different scales: (Related Post: Cottonseed oil mill plant cost >>)

| Processing Capacity (tons/day) |

Estimated Investment Cost (USD) |

Main Components |

| 1-10 tons/day |

$80,000-200,000 |

Includes crystallization tanks, filter presses, cool units, and basic control systems. Features low automation levels with high labor costs. |

| 10-20 tons/day |

$200,000-420,000 |

Configured with continuous crystallization systems, larger-area filter presses, and PLC automated control systems. Equipment investment increases, with economies of scale beginning to appear. |

| 20-50 tons/day |

$420,000-850,000 |

A complete automated production line, including multiple crystallization towers, large filter press units, and a central control room. |

Conclusion

Henan Huatai Intelligent Equipment Group specializes in designing and installing cottonseed oil fractionation plants and cottonseed oil production line tailored to your specific needs and budget. Whether you're starting small or planning a large-scale plant, we provide comprehensive support from initial consultation through installation and staff training.

Contact us today for a free consultation and customized quotation. Our experts are ready to answer your questions and help you make informed decisions about your investment.

![]() Service Coverage

Service Coverage

![]() FAQ

FAQ