Corn Oil Processing Plant | Corn Germ Oil Extraction Process

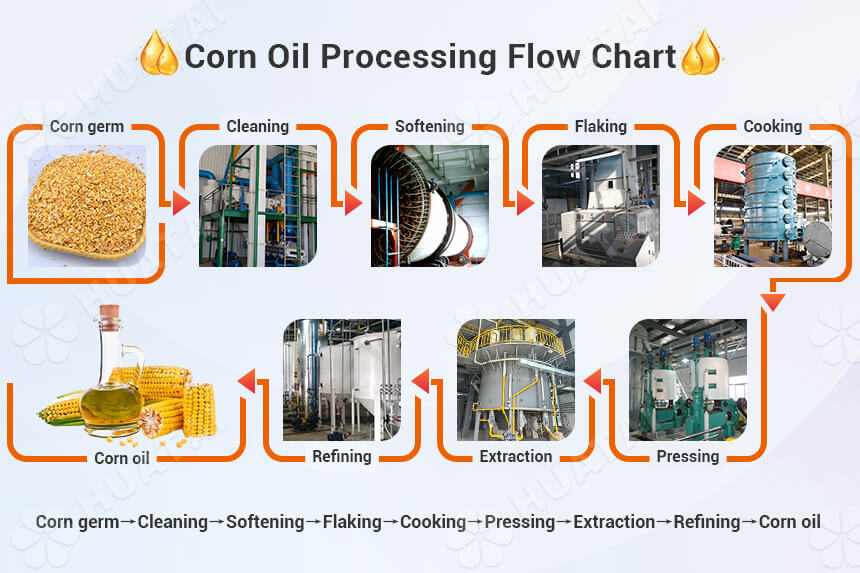

The corn oil processing plant extracts oil from corn germ using methods such as pressing or a combination of pre-pressing and solvent extraction.

LEARN MOREThe corn oil processing plant extracts oil from corn germ using methods such as pressing or a combination of pre-pressing and solvent extraction.

LEARN MOREThe linseed oil refining process includes degumming, neutralization, bleaching, and deodorization to convert crude linseed oil into edible oil suitable for human consumption.

LEARN MOREThis article provides a comprehensive overview of linseed oil manufacturing plant, from its nutritional value and extraction methods to market analysis.

LEARN MOREExplore everything about cottonseed oil fractionation, including process, nutritional value, and setting up costs for plants of different scales.

LEARN MORESoybeans are widely recognized for their rich nutritional profile, serving as a vital source of protein and oil for both human consumption and animal feed. In

LEARN MOREExplore the complete process of cottonseed oil mill plant and different scales of costs, start investing in cottonseed oil industry now!

LEARN MORECottonseed oil refinery plant converts crude oil into edible oil for direct consumption through degumming, neutralization, bleaching, deodorization, and winterization.

LEARN MOREThe cold pressed canola oil extracts oil directly from canola seeds using purely physical mechanical pressure at 45-60℃.

LEARN MOREThe canola oil solvent extraction process uses hexane to extract oil from canola seeds or pre-pressed canola cakes, higher oil yield.

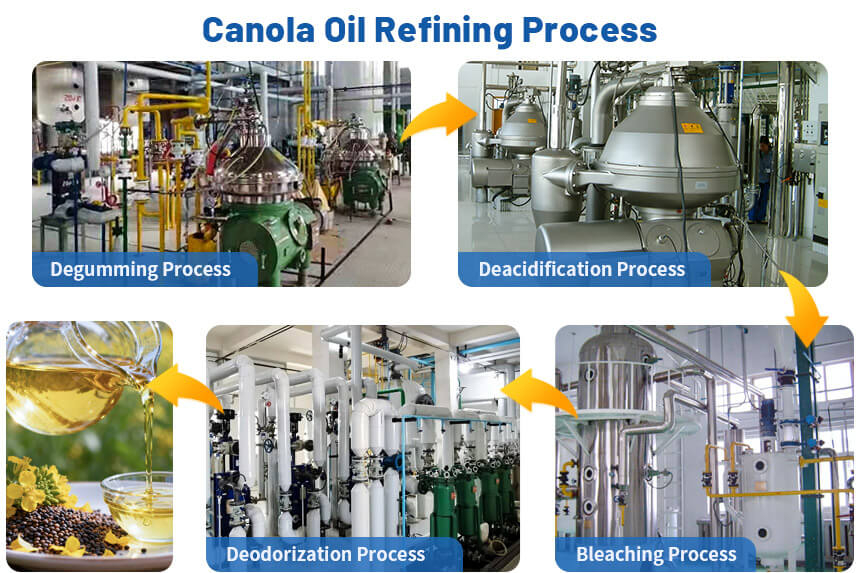

LEARN MOREThe canola oil refining process transforms crude canola oil into edible oil suitable for direct human consumption through degumming, deacidification, bleaching and deodorization.

LEARN MORE

膨化机介绍-封面_副本.jpg)